Patents

Literature

63results about How to "Axially takes up little space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

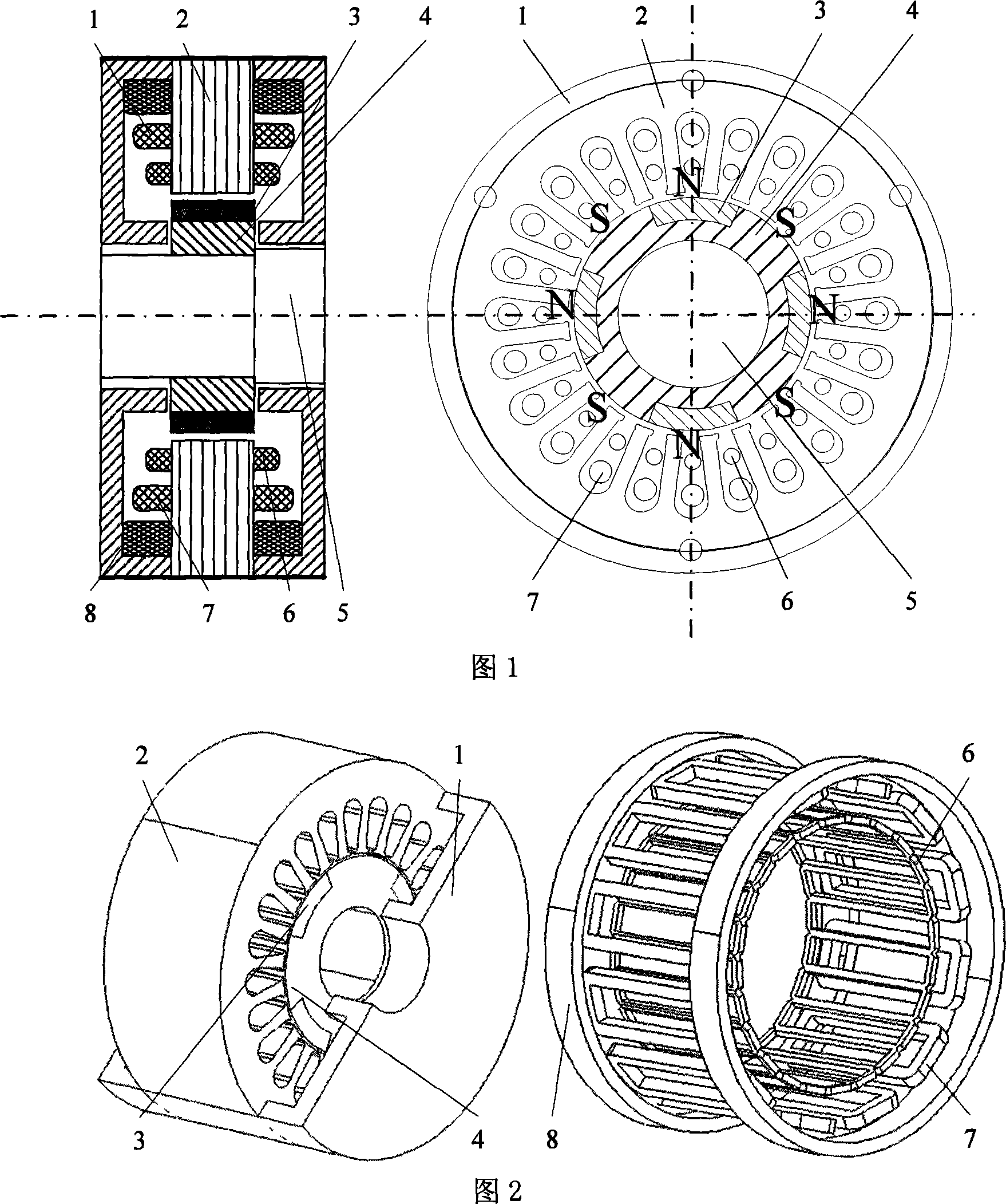

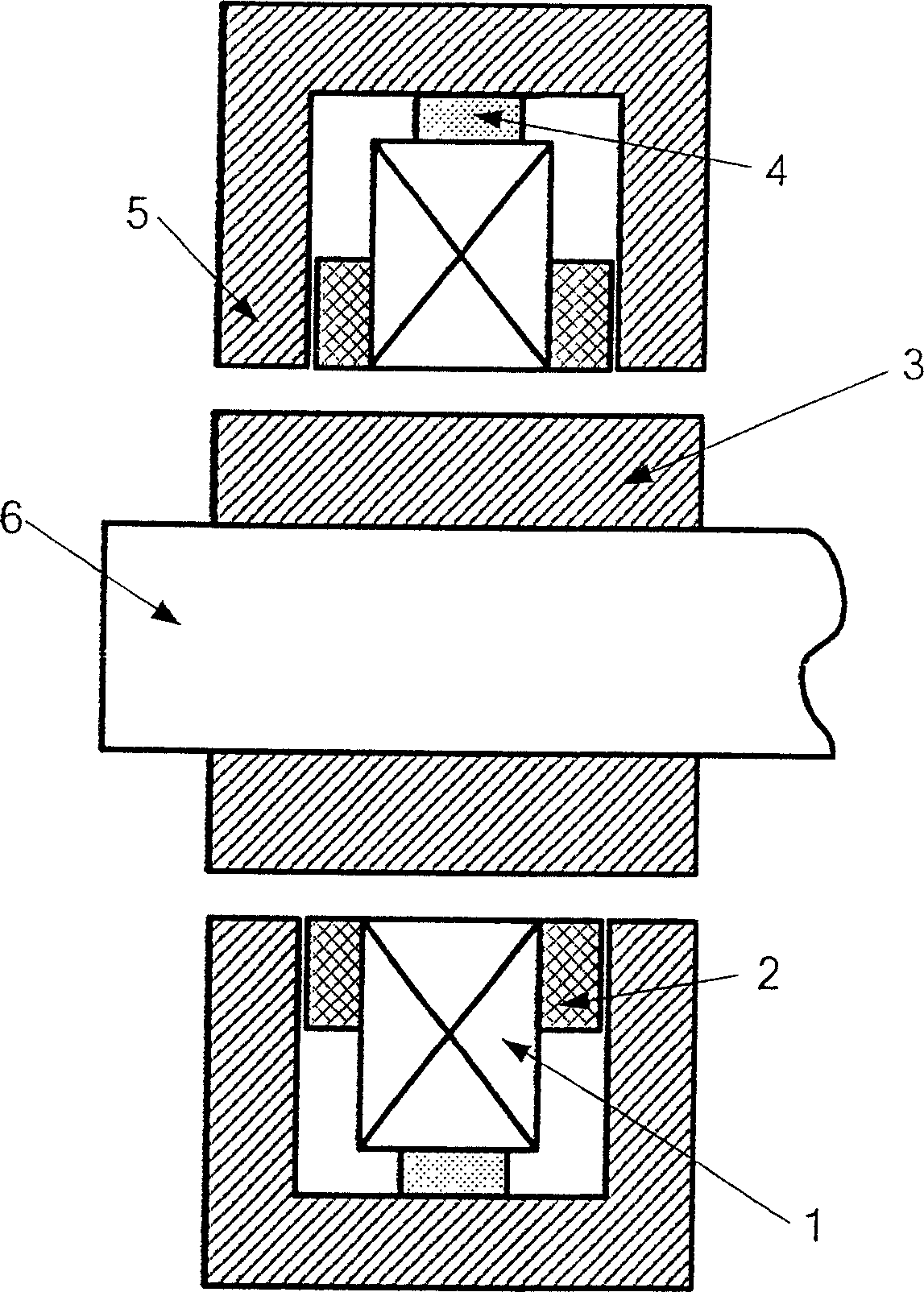

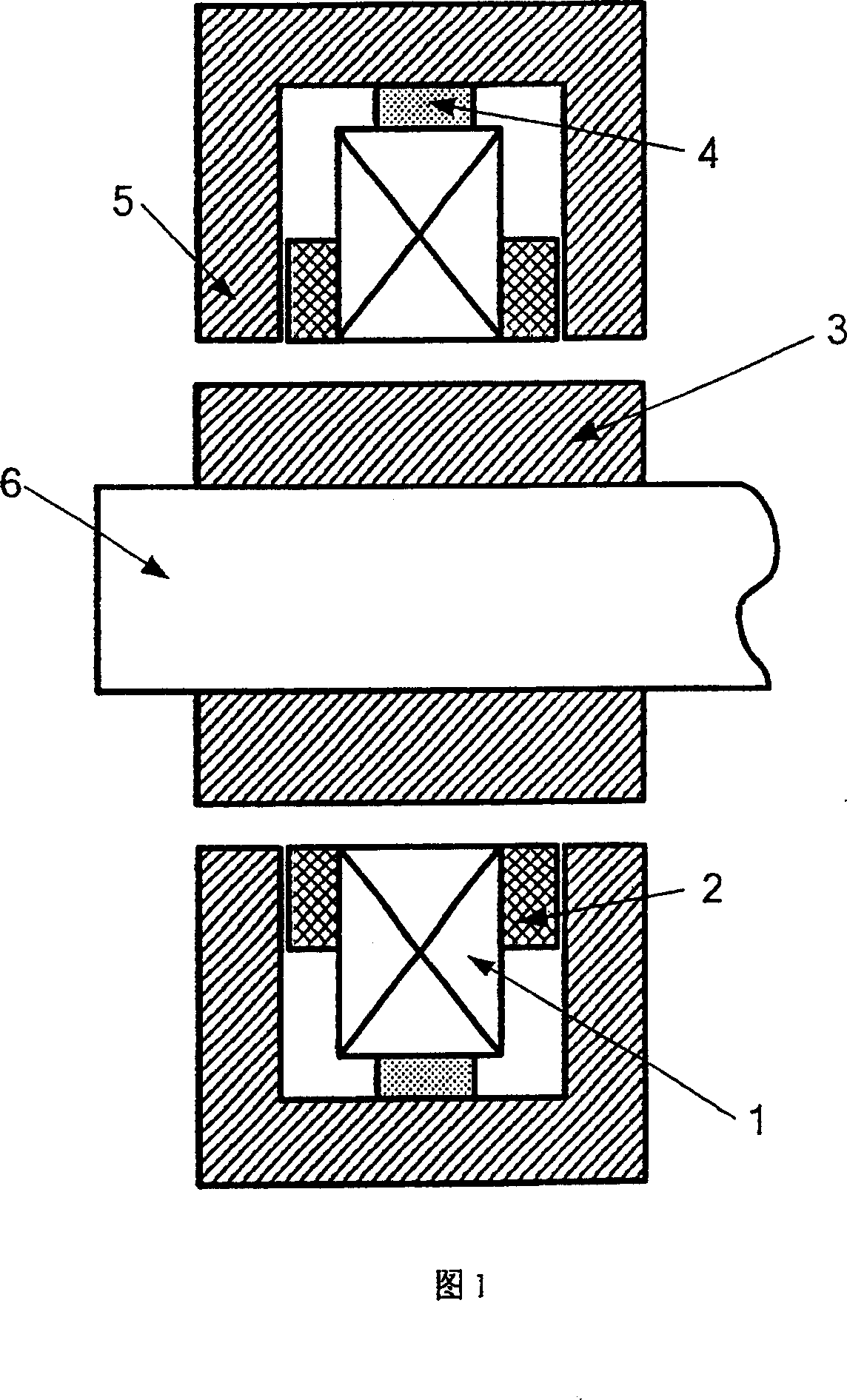

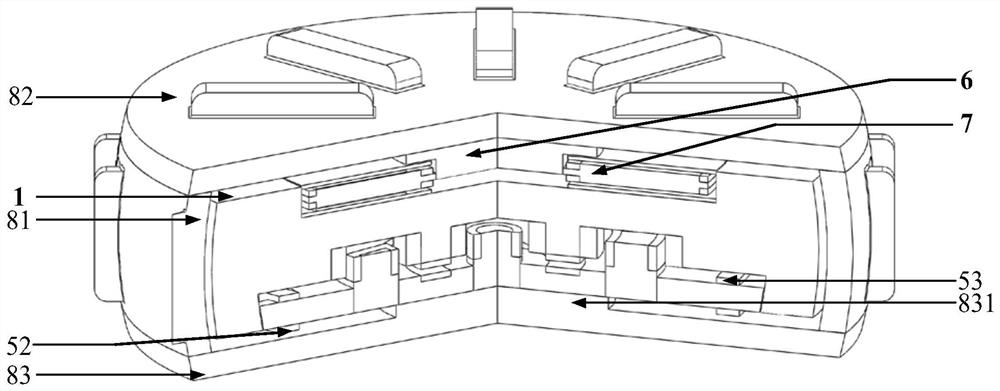

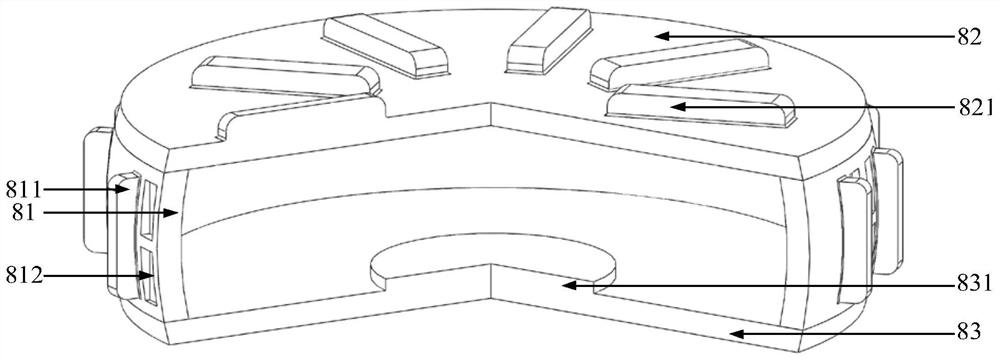

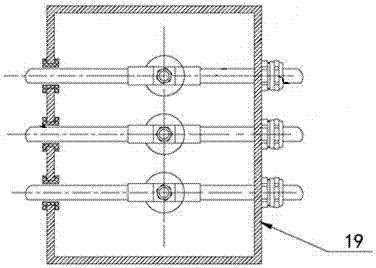

Three-freedom consequent pole permanent magnet motor without bearing of axial direction initiative suspending

InactiveCN101207310AMagnetic Control EasyLevitation current is smallMechanical energy handlingMagnetic holding devicesMagnetic bearingPermanent magnet motor

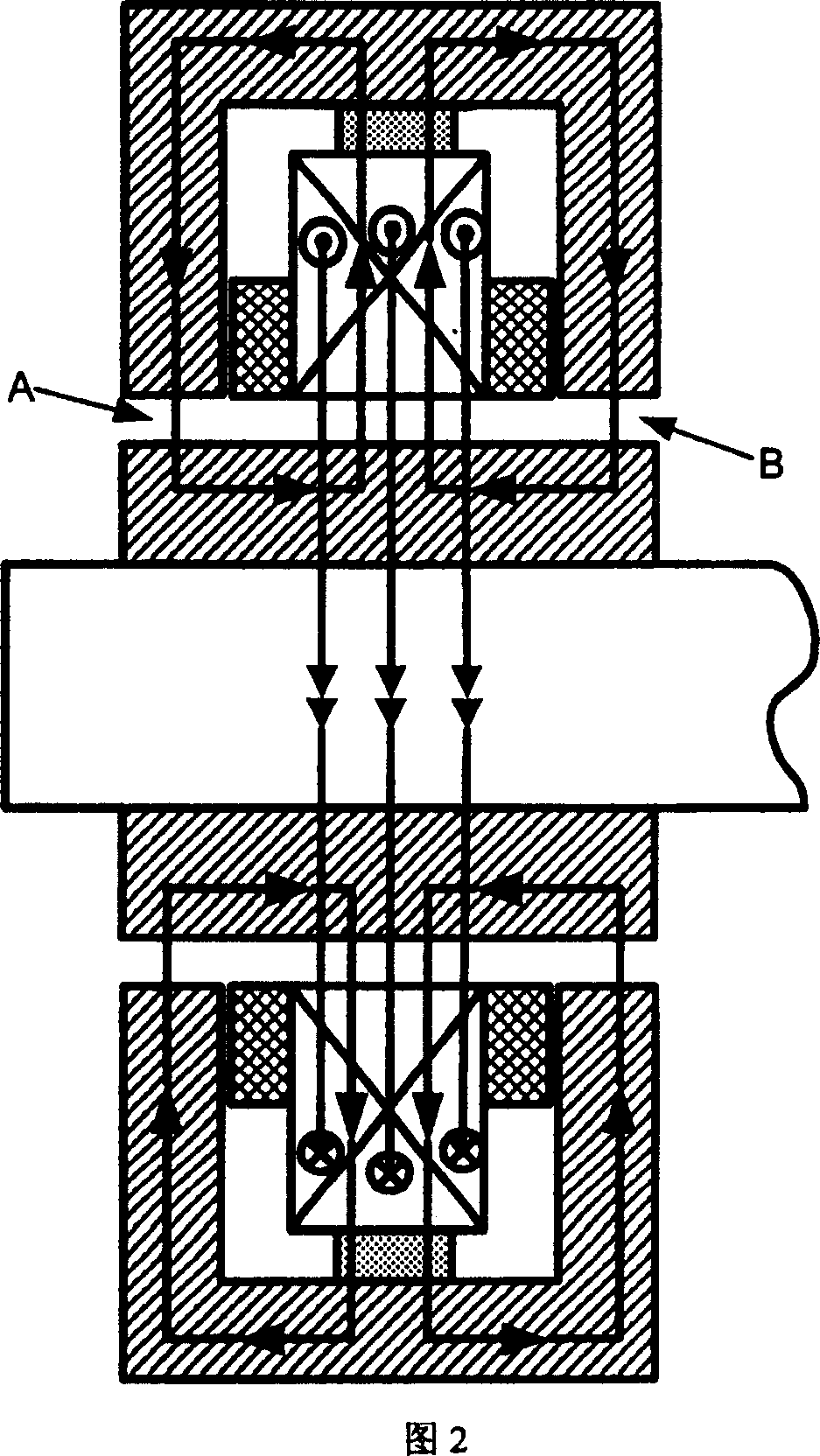

The invention relates to an axial initiative-suspension three-dimensional bearing-free alternative-pole permanent-magnetic machine, which belongs to a bearing-free magnetic-suspension motor. The machine comprises two axial stator cores (1) that are provided with axial suspension controlling windings (8) that are serially connected with each other, a radial stator core (2) that is provided with a set of four-pair-pole torque controlling windings (7) and a set of one-pair-pole radial suspension controlling windings (6), a rotor core (4) that is provided with four homo-polar magnetizing permanent-magnets (3) and a rotor rotating shaft (5) that is enclosed with the rotor core (4). The motor has simple and compact structure, is free from additional axial magnetic bearing, integrates the motor rotation and axial and radial simultaneous-suspension functions of the rotor, has high integration, enlarges the suspension freedom of the bearing-free motor, simplifies the system structure, reduces the volume, the weight and the cost of the system, and has broad application prospect and important significance in different high-speed magnetic-suspension motor systems.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

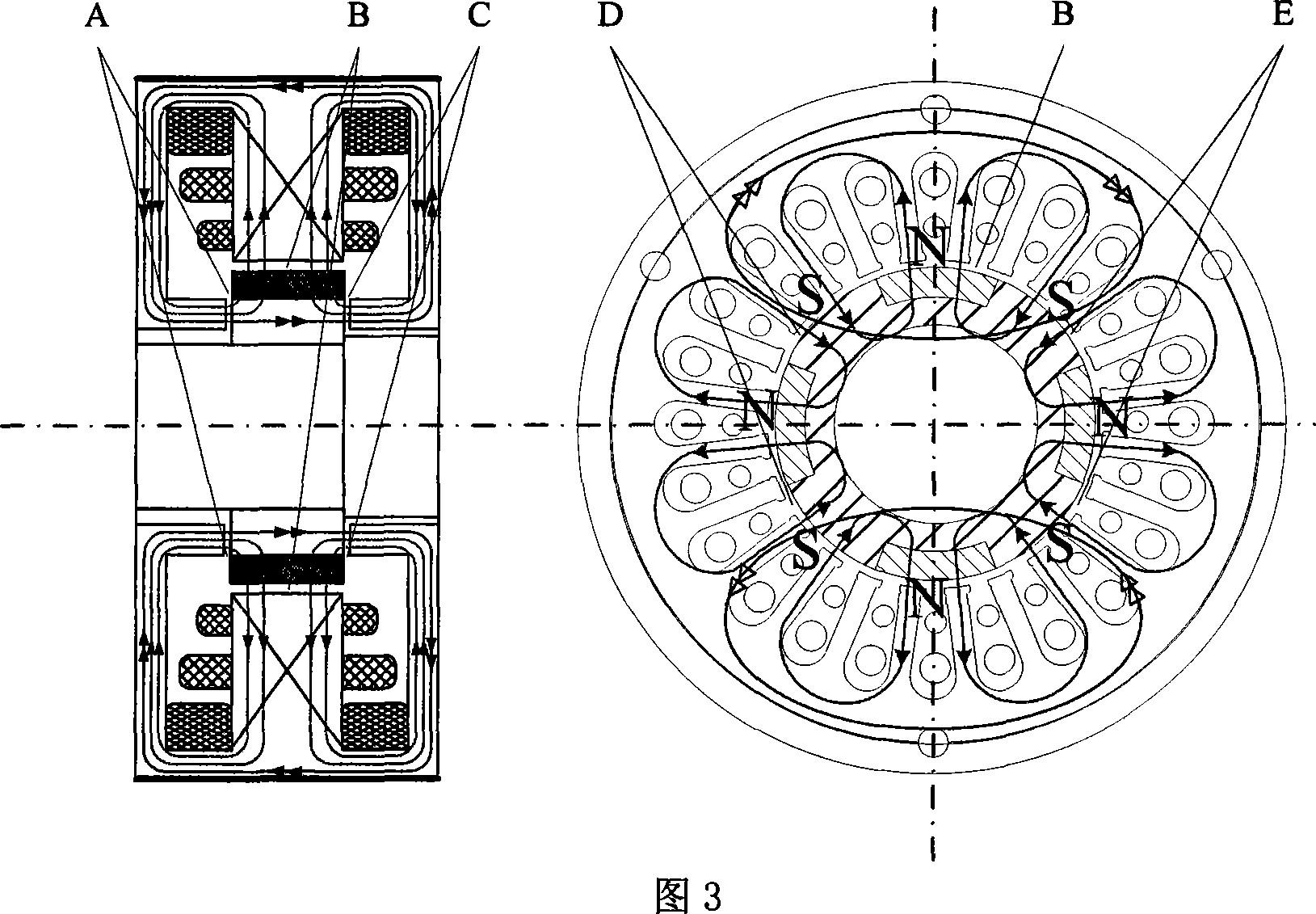

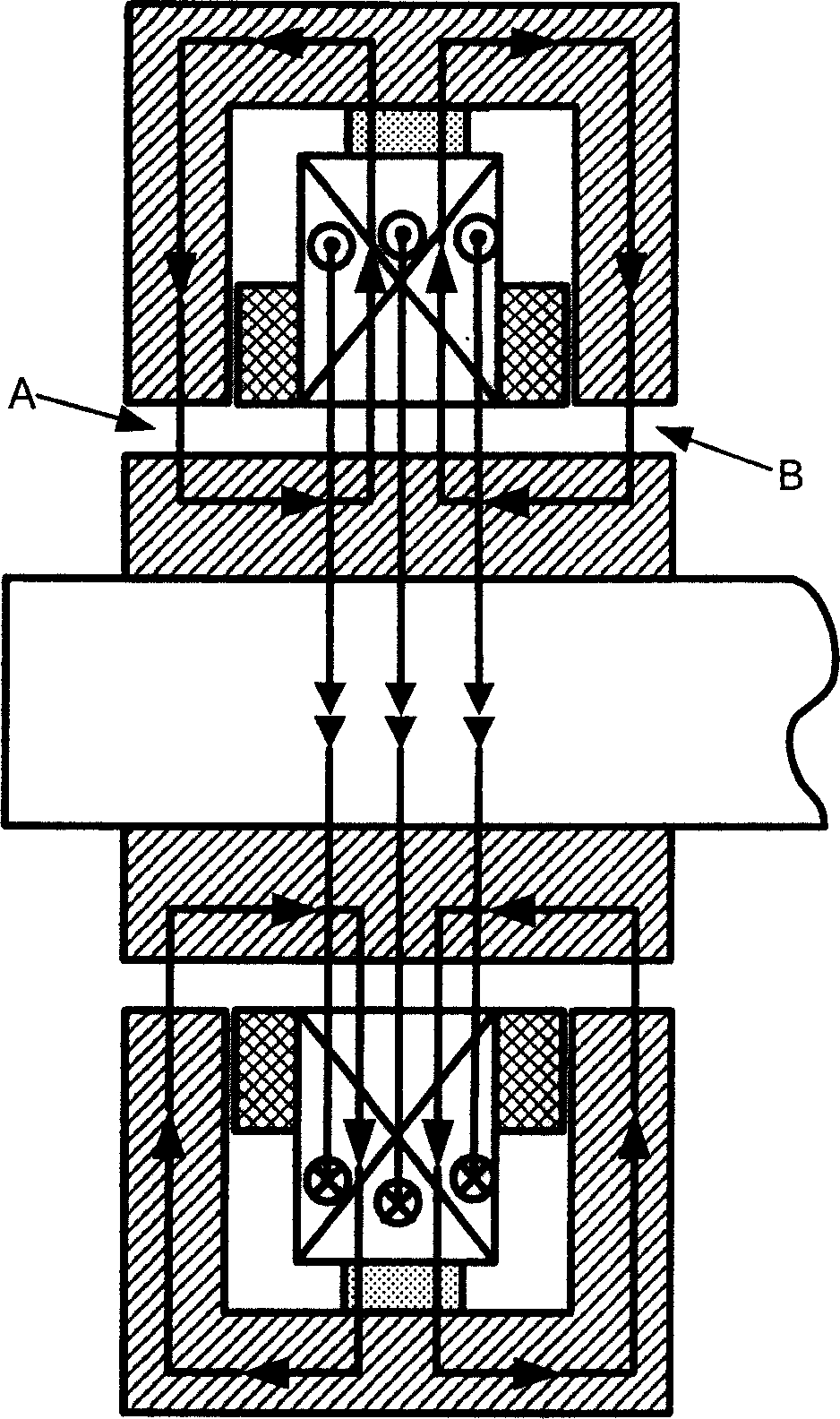

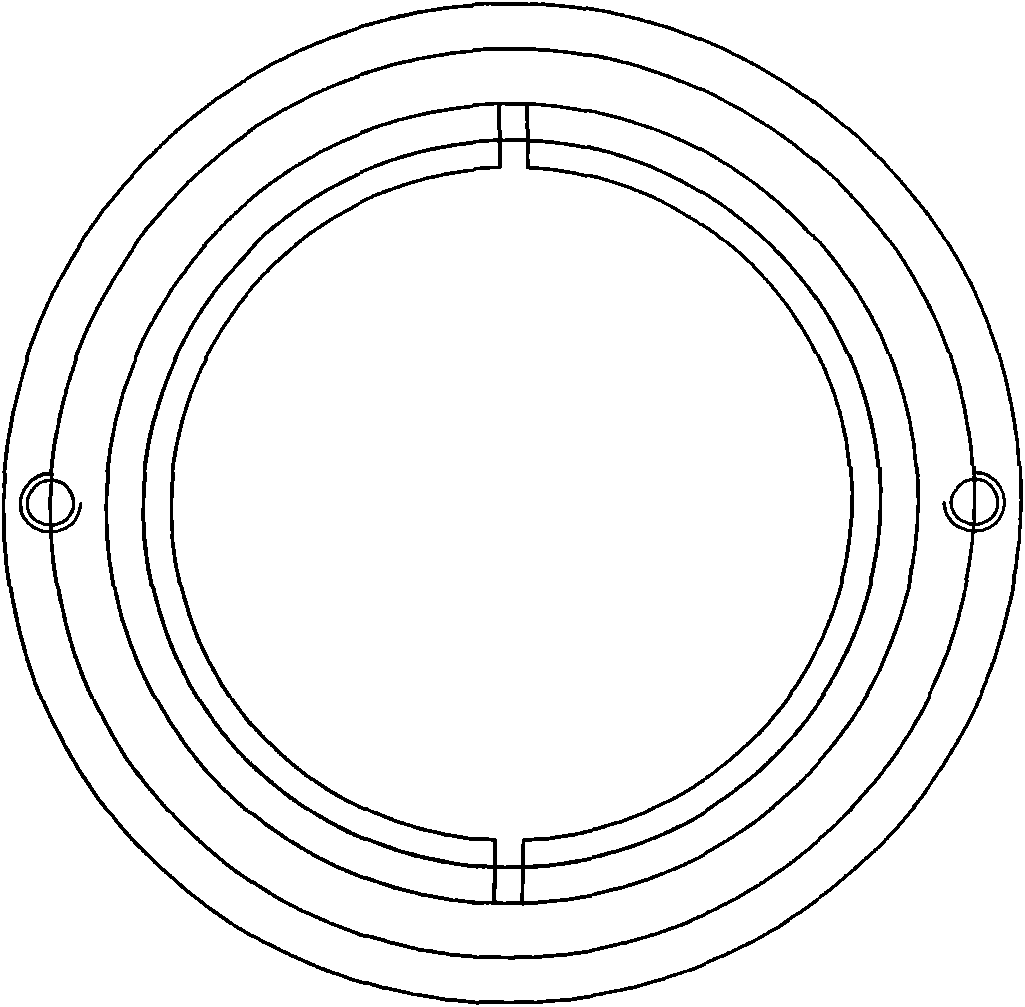

Permanent magnet offset radial magnetic bearing

The invention relates to a permanent-magnet offset radial magnetic bearing. It includes radial stator, control coil, circle permanent magnet, exterior magnetic pole iron core and rotator covered by rotator iron core. The permanent-magnet offset radial magnetic bearing has advantage of simple structure, small volume, and light weight. It has a broad application prospect in kinds of magnetic suspension systems that take up small space on radial direction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

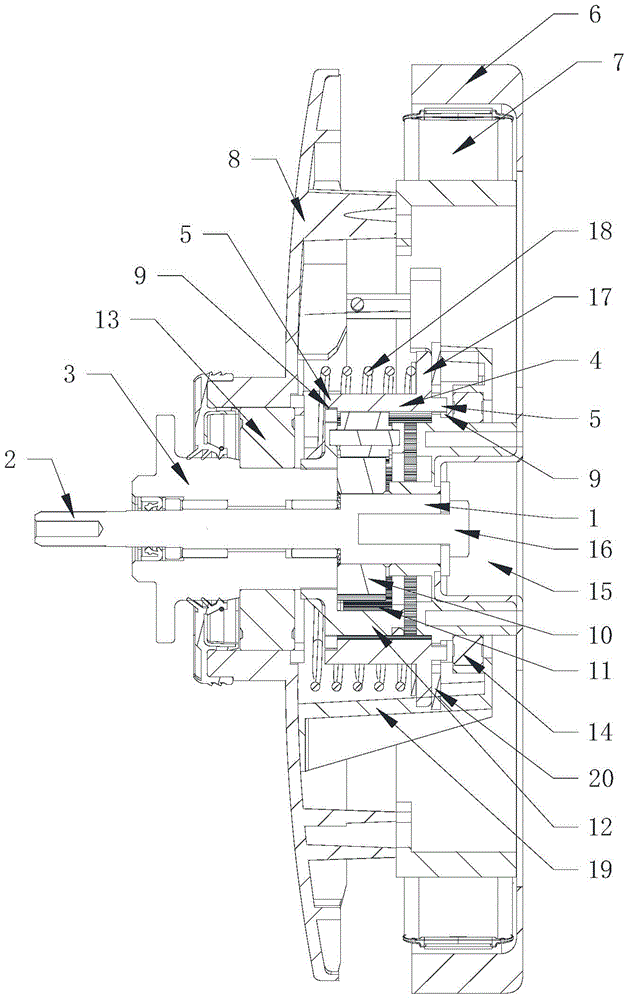

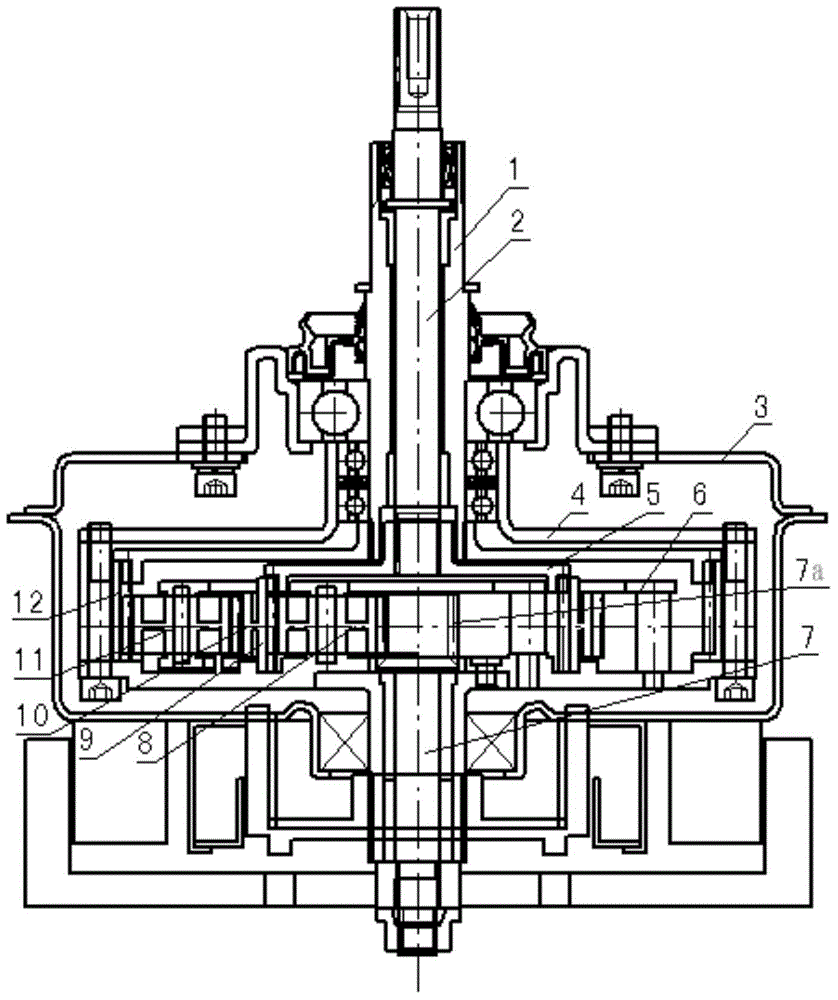

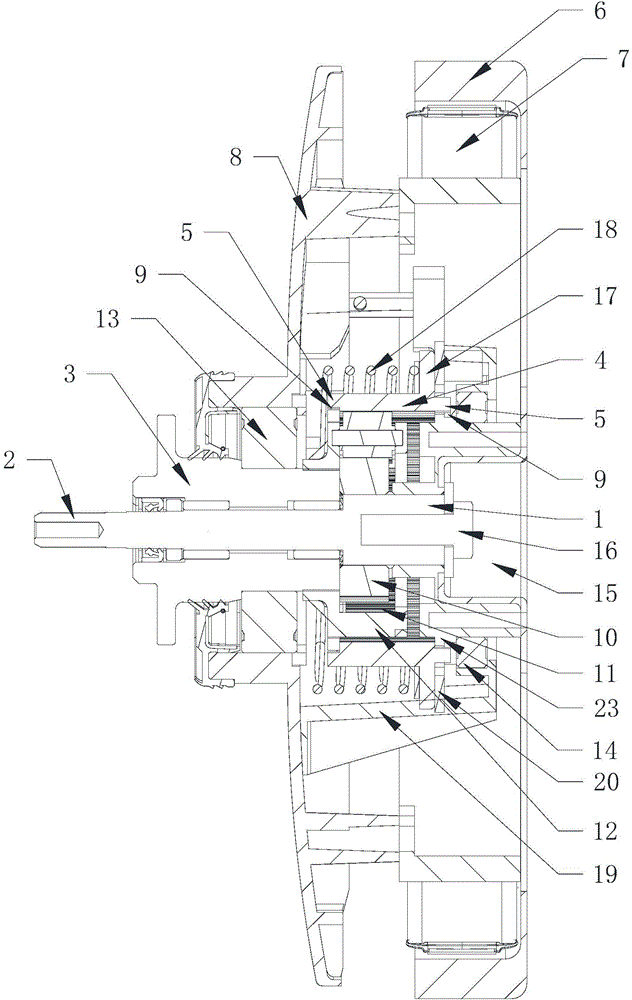

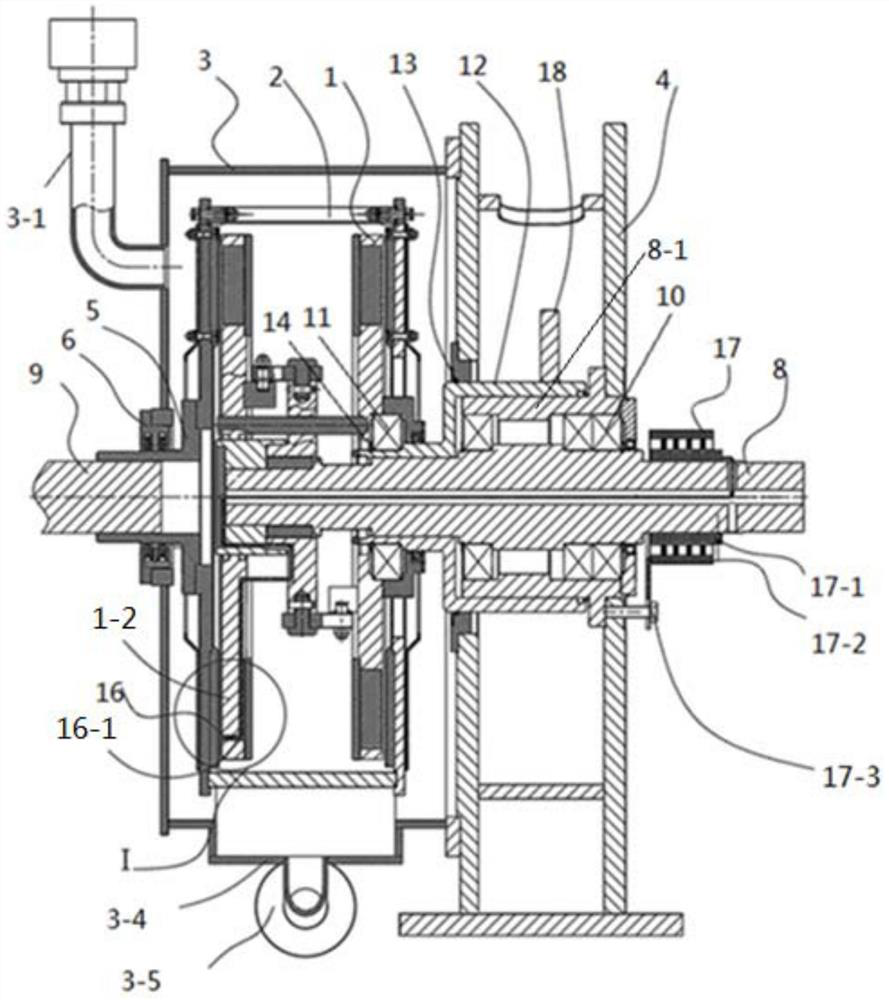

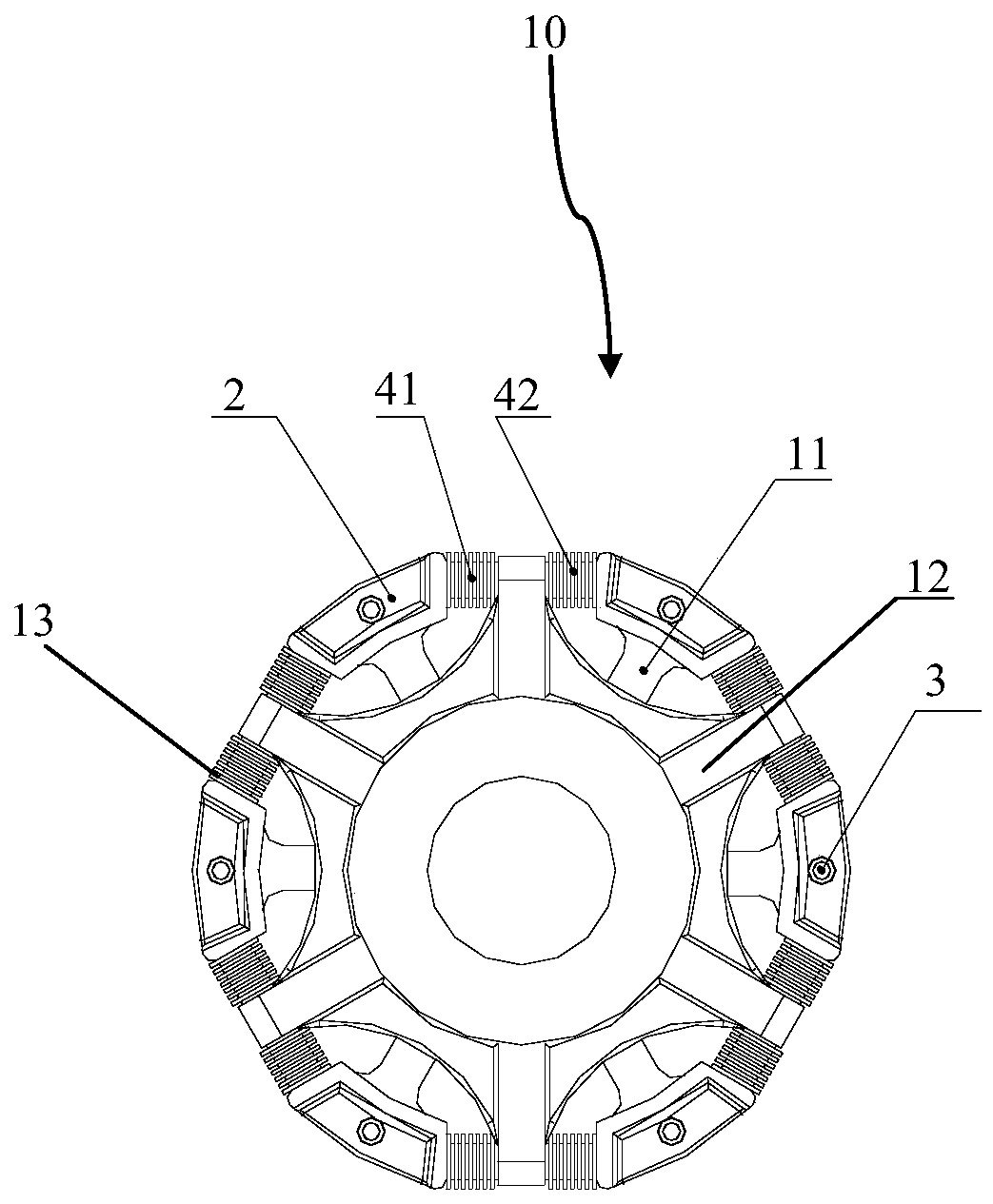

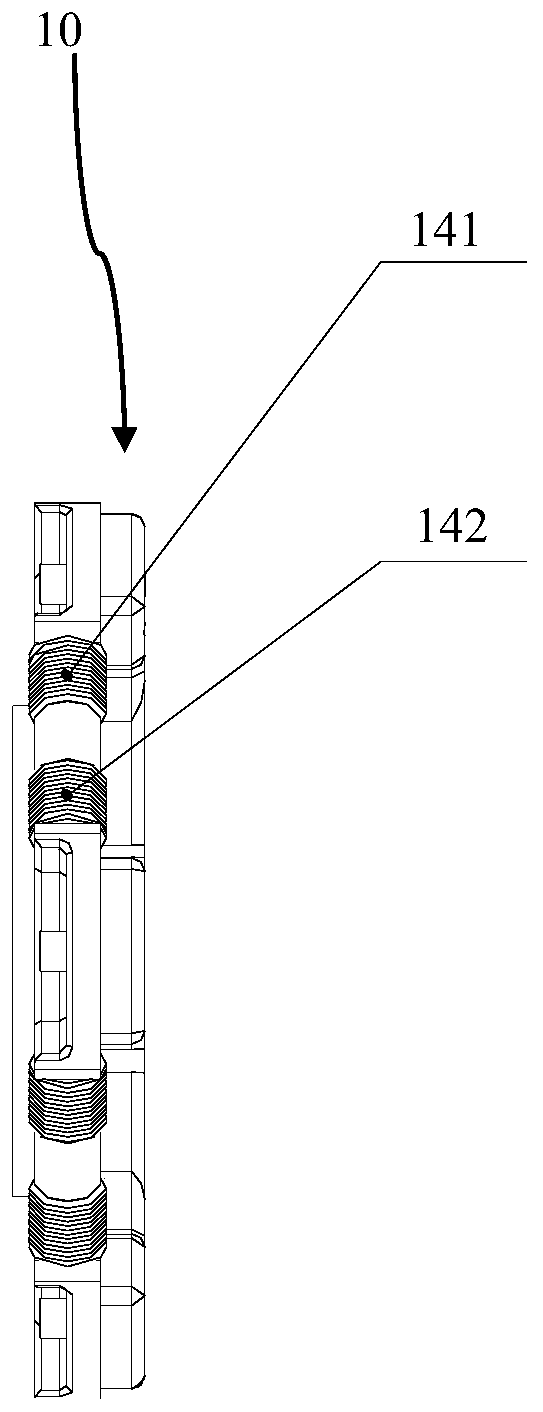

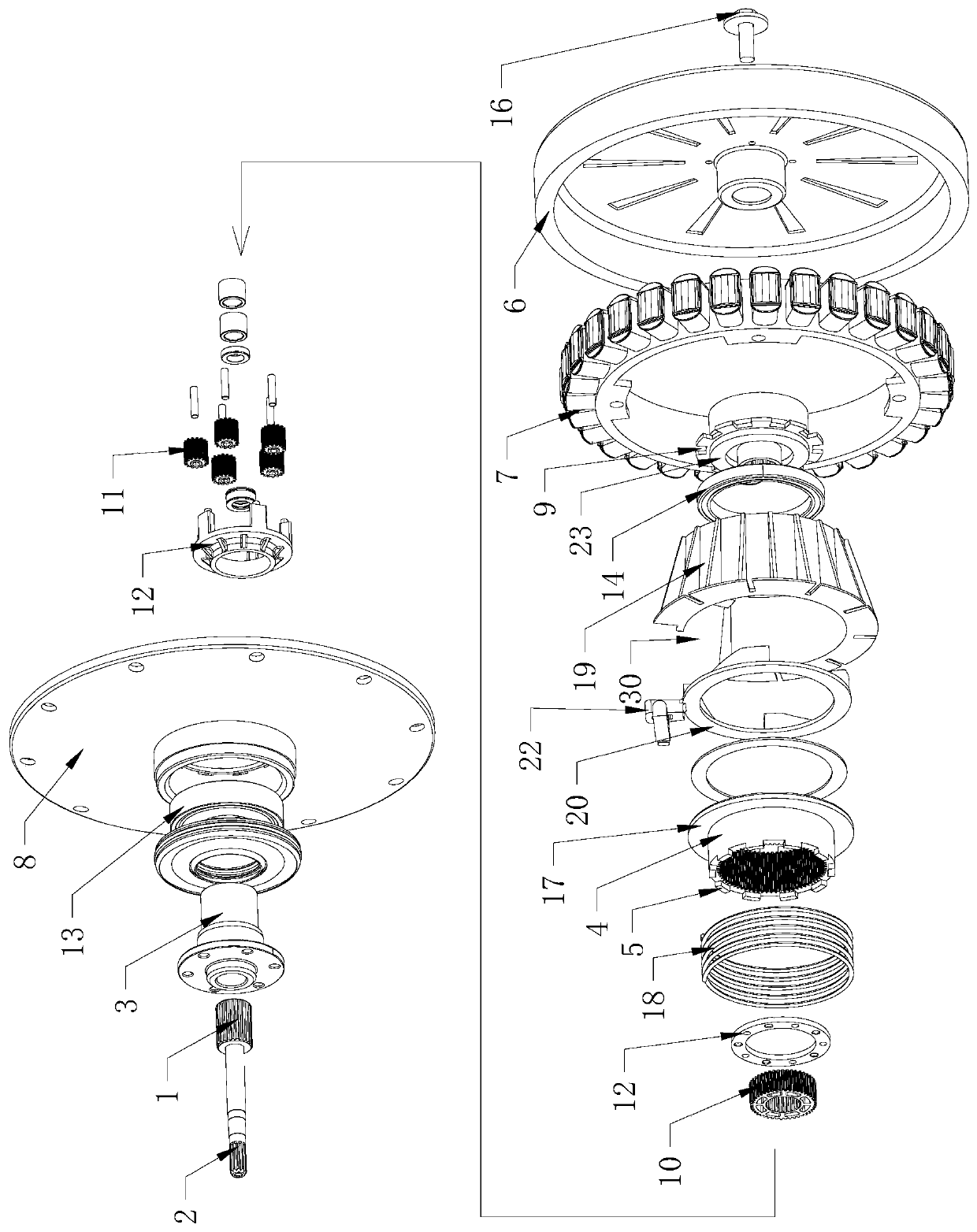

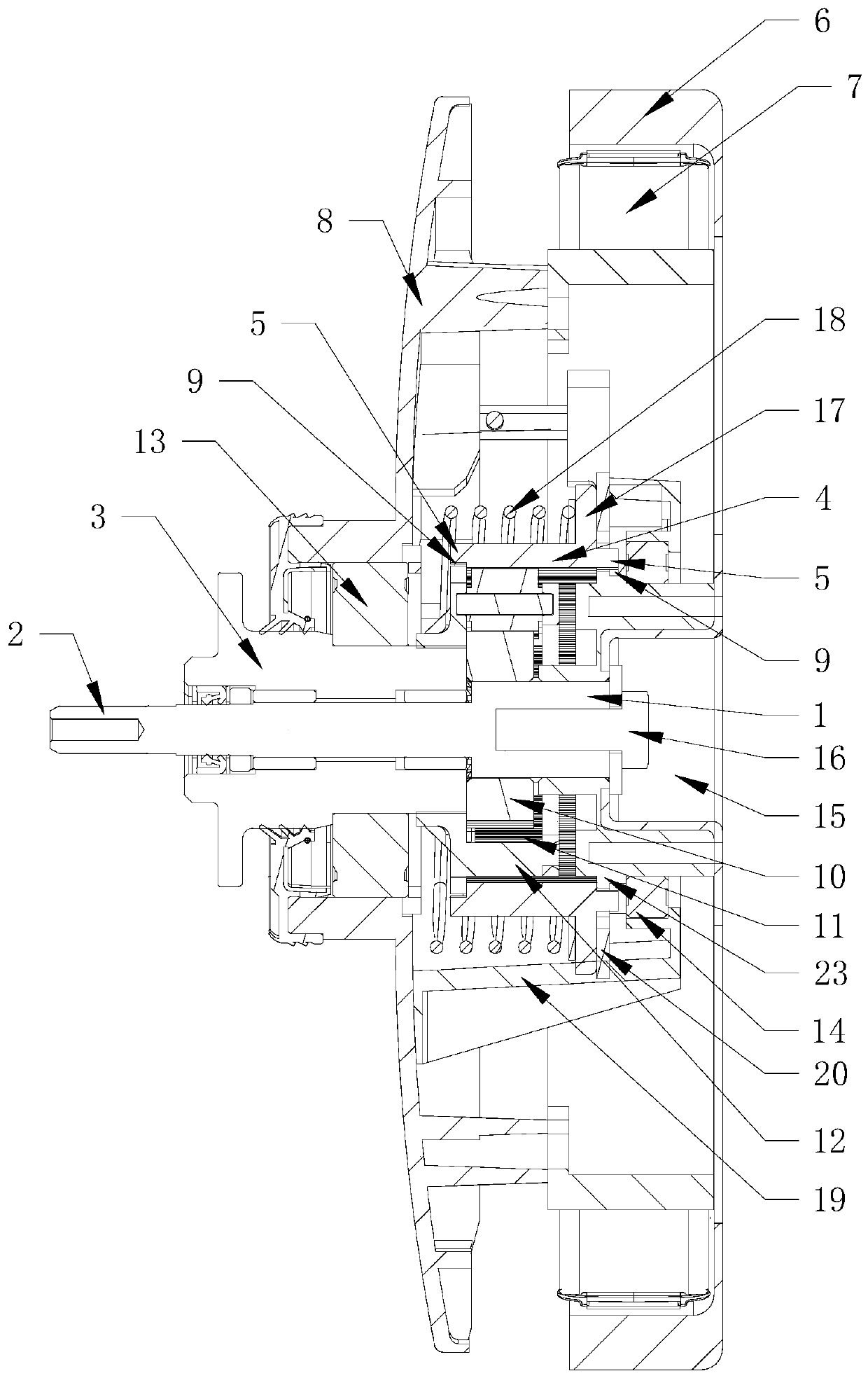

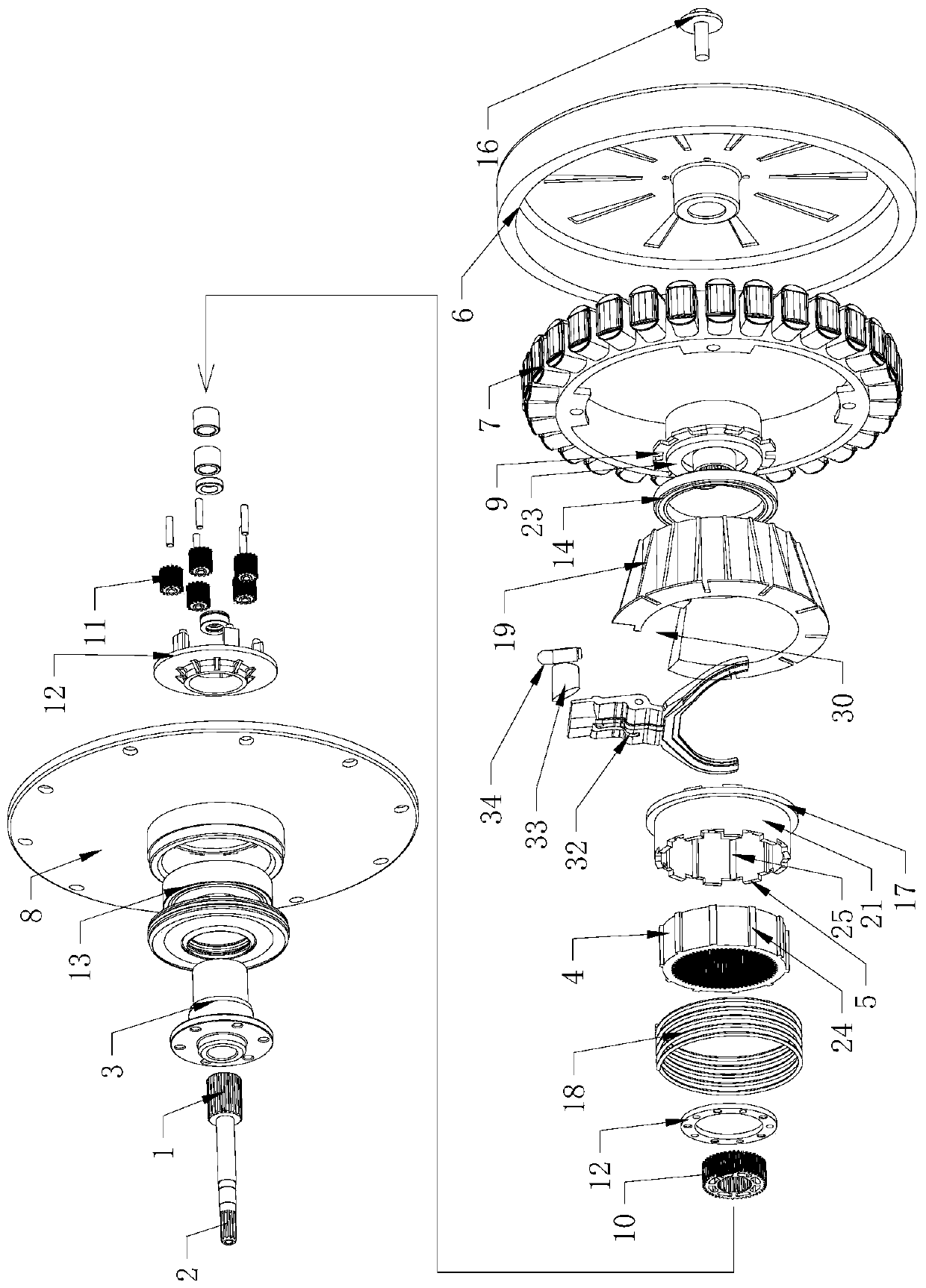

Washing machine deceleration clutch and washing machine

ActiveCN105463769AAxial space savingCompact structure and installationClutchesOther washing machinesEngineeringDrive motor

The invention provides a washing machine deceleration clutch and a washing machine. The washing machine deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is formed by a clutch platen and a clutch shaft sleeve; the clutch shaft sleeve covers the circumferential periphery of the deceleration device; the clutch platen rotationally move surrounding the axis to drive the clutch shaft sleeve to axially move; a first position of the clutch shaft sleeve movement is connected with a fixing device; the fixing device and an external cylinder of the washing machine are relatively fixed, so a washing work condition can be achieved; a second position of the clutch shaft sleeve movement is connected with a rotor of a direct-drive motor, so a dehydrating work condition can be achieved. The clutch device is arranged on the circumferential periphery of the deceleration device, so overall height of the deceleration clutch can be reduced, washing machine size can be reduced with the same of the washing capacity or washing capacity can be increased with the same of the washing machine size.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Permanent magnet offset radial magnetic bearing

The invention relates to a permanent-magnet offset radial magnetic bearing. It includes radial stator, control coil, circle permanent magnet, exterior magnetic pole iron core and rotator covered by rotator iron core. The permanent-magnet offset radial magnetic bearing has advantage of simple structure, small volume, and light weight. It has a broad application prospect in kinds of magnetic suspension systems that take up small space on radial direction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

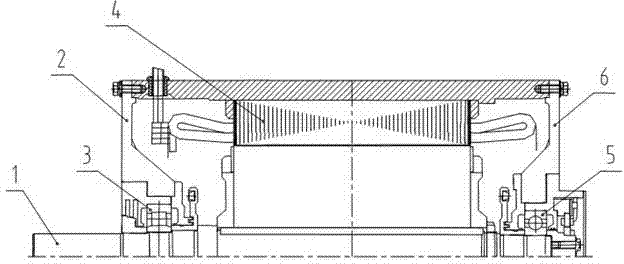

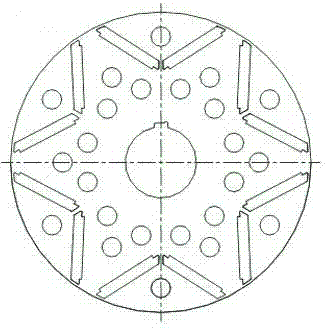

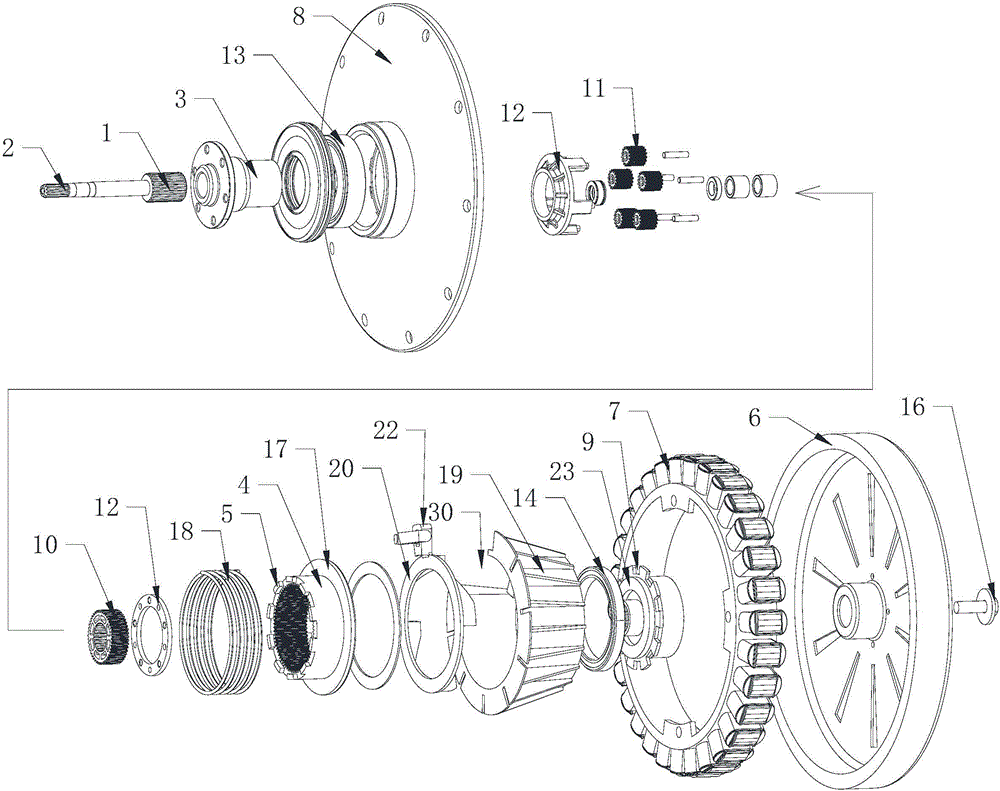

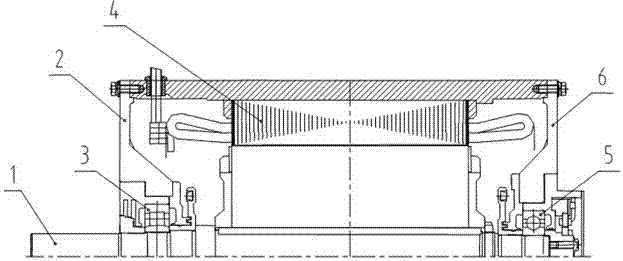

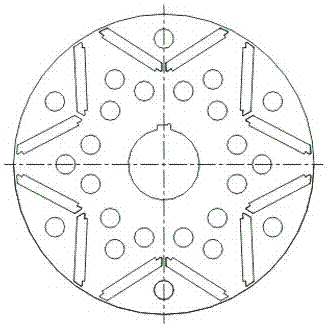

Permanent-magnet synchronous traction motor for motor train

ActiveCN104767337AImprove efficiencyIncrease powerSynchronous machine detailsMagnetic circuit rotating partsPunchingPermanent magnet synchronous motor

The invention relates to a motor, in particular to a permanent-magnet synchronous traction motor for a motor train. The permanent-magnet synchronous traction motor for the motor train solves the problem that an existing permanent-magnet synchronous motor is not suitable for being directly used as a permanent-magnet synchronous traction motor for a motor train due to structure defects. The motor adopts a novel rotor magnetic circuit structure punching plate, a high-integration compact type rotor structure, a detachable connecting box structure and a lead structure. A connecting box can be conveniently disassembled so that the motor can be installed easily. A U-shaped magnetic circuit permanent magnet structure of an inner rotor is adopted, the magnetic separation bridge and circular bead design is added, and therefore the start and overload capacity of the motor can be improved. A rotor pressing ring at the driving end integrates rotor core pressing, permanent magnet end face pressing, rotor dynamic balancing and an inner seal ring labyrinth seal structure into a whole, the advantages that the structure is compact, the axial occupied space is small, and the installation is convenient are achieved, and the motor can be widely applied in the field of locomotive trains. According to the research, development and the operation of the permanent-magnet synchronous traction motor for the motor train, realistic bases are supplied for the permanent-magnet motor to research and develop a permanent-magnet traction motor structure with higher power, higher rotation speed and higher power density.

Owner:CRRC YONGJI ELECTRIC CO LTD

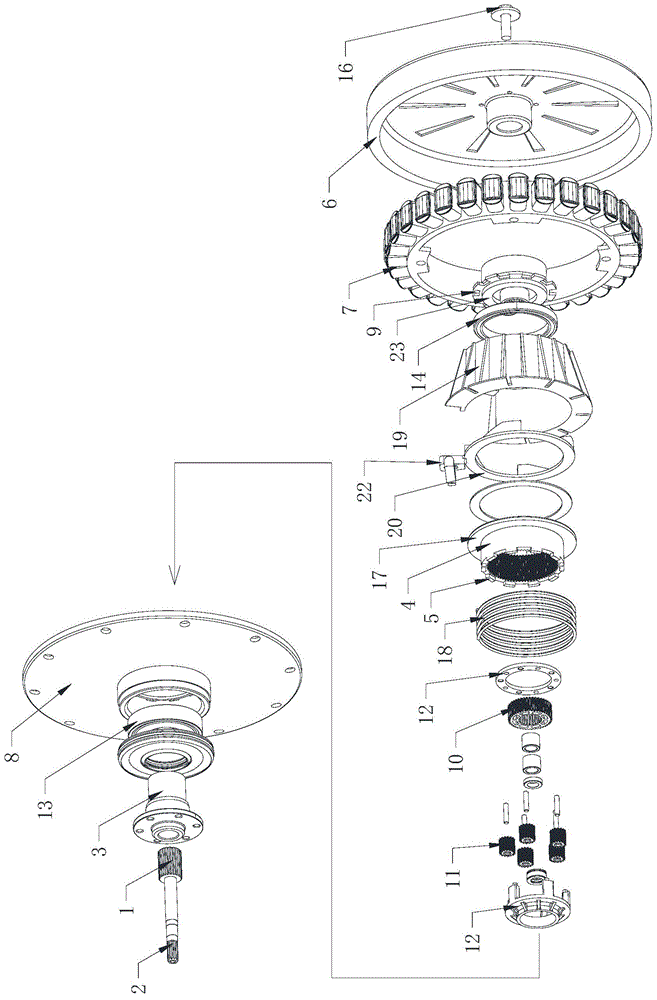

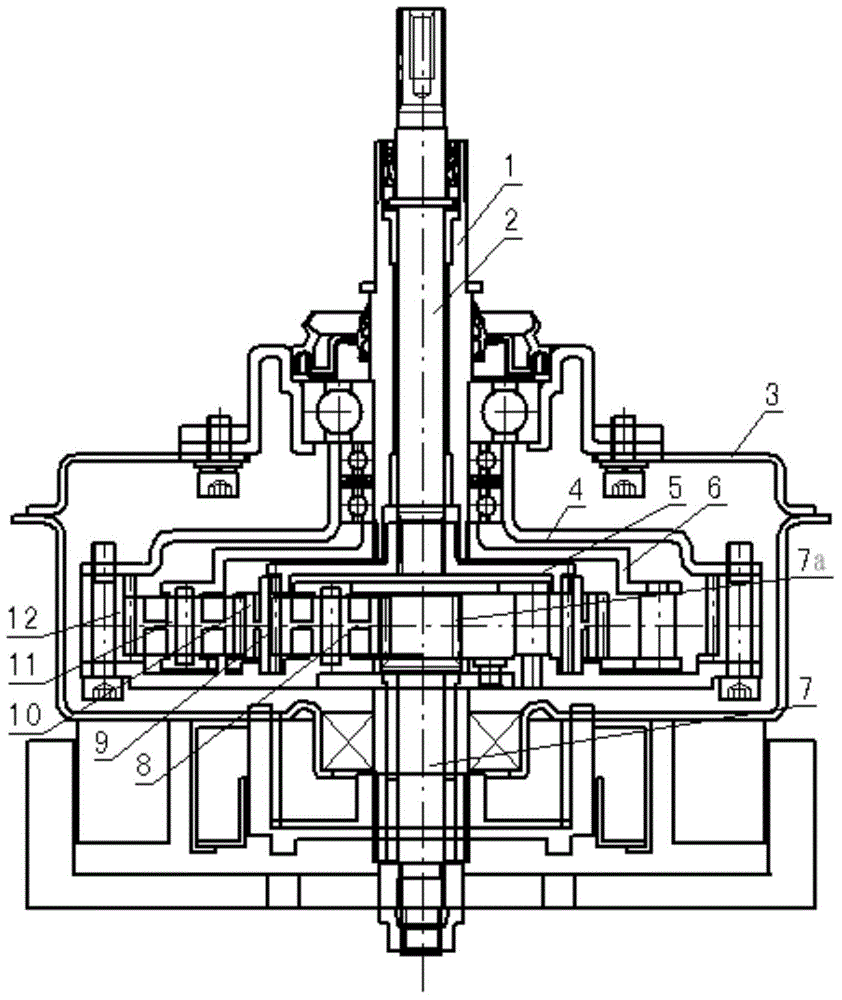

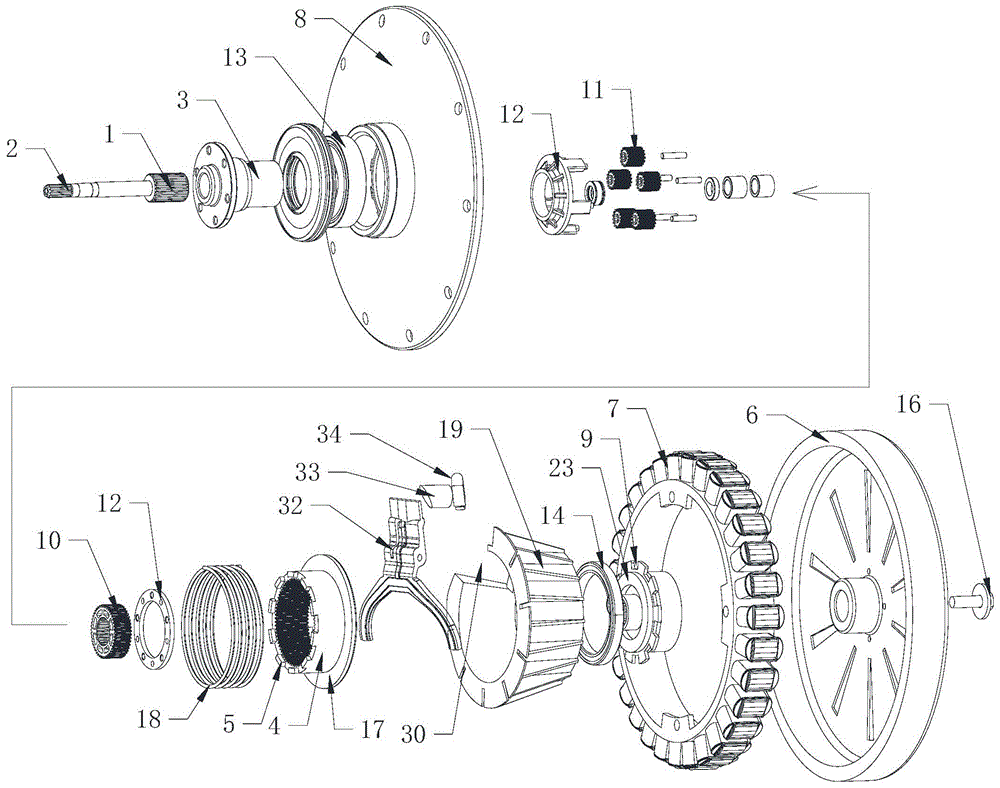

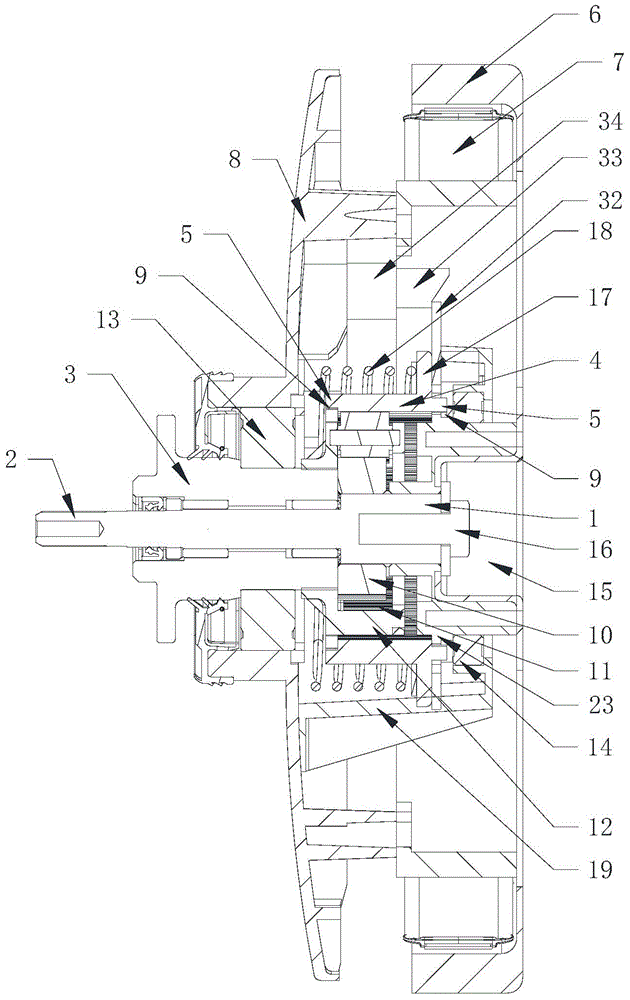

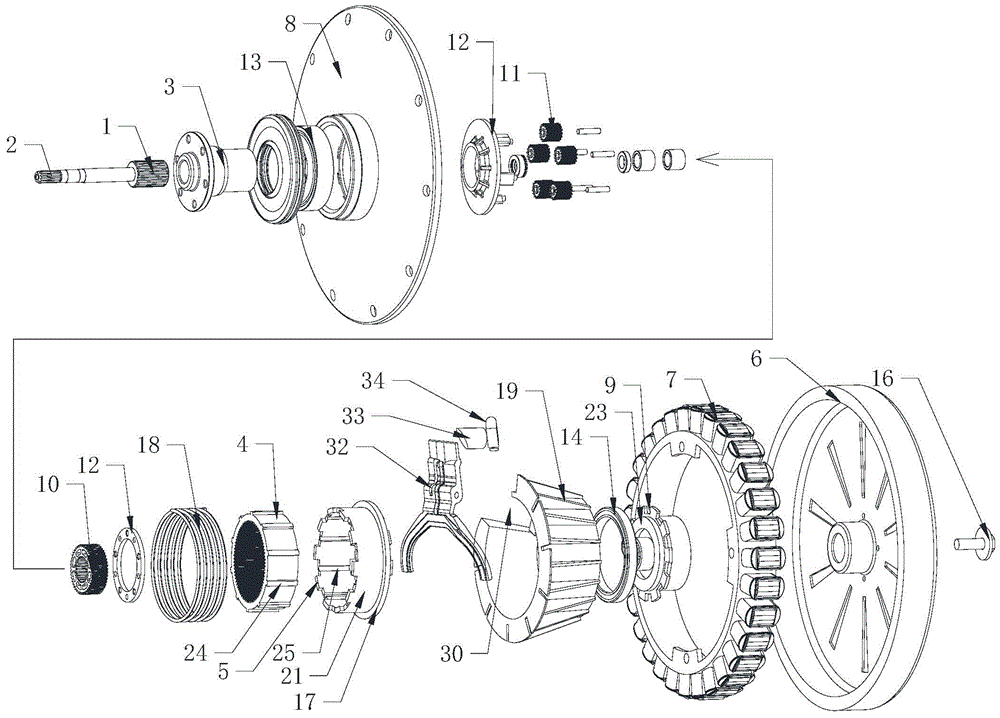

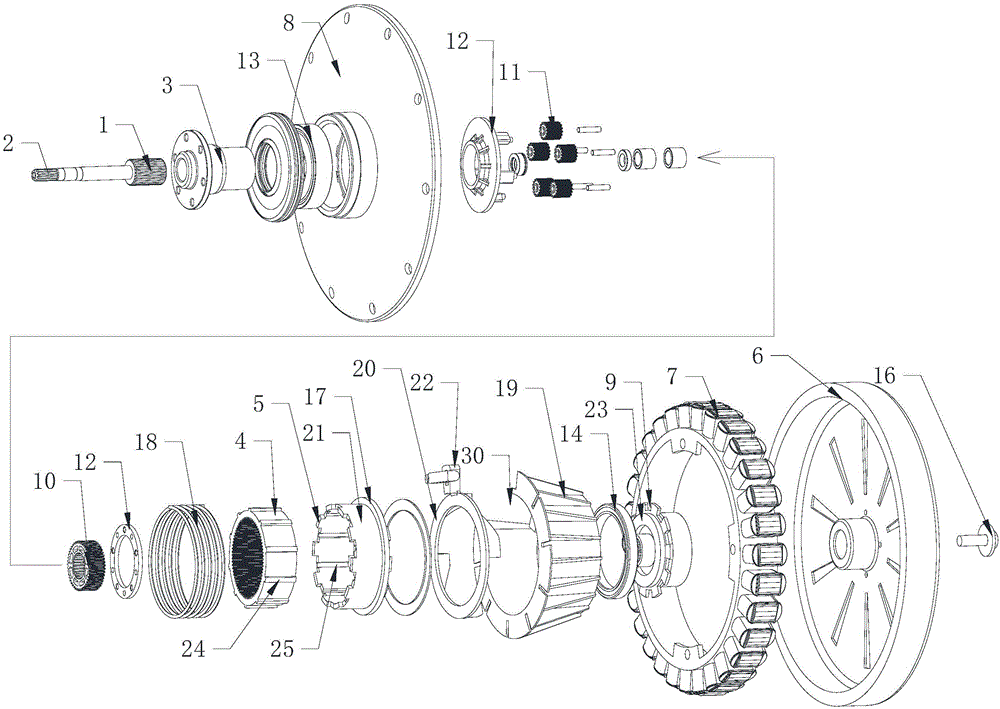

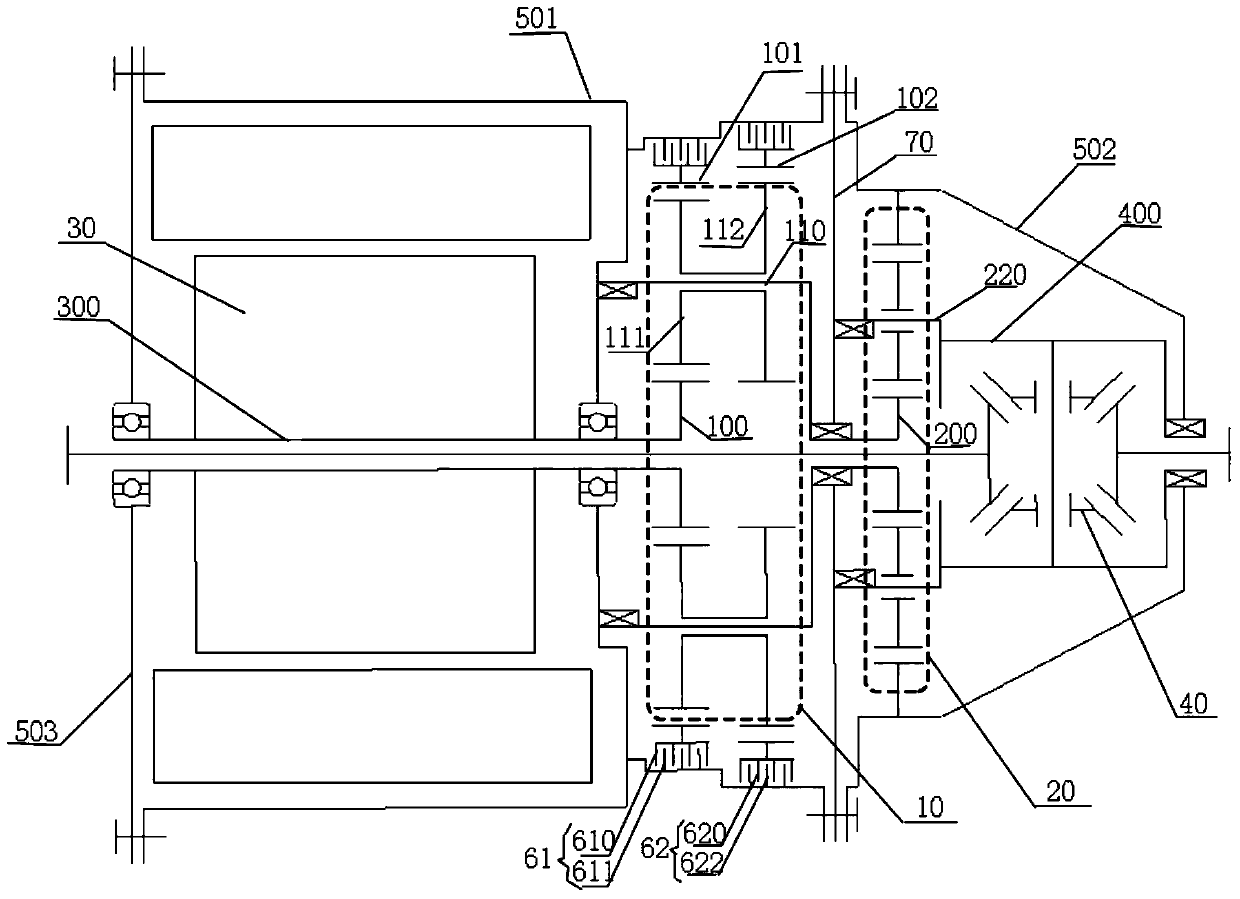

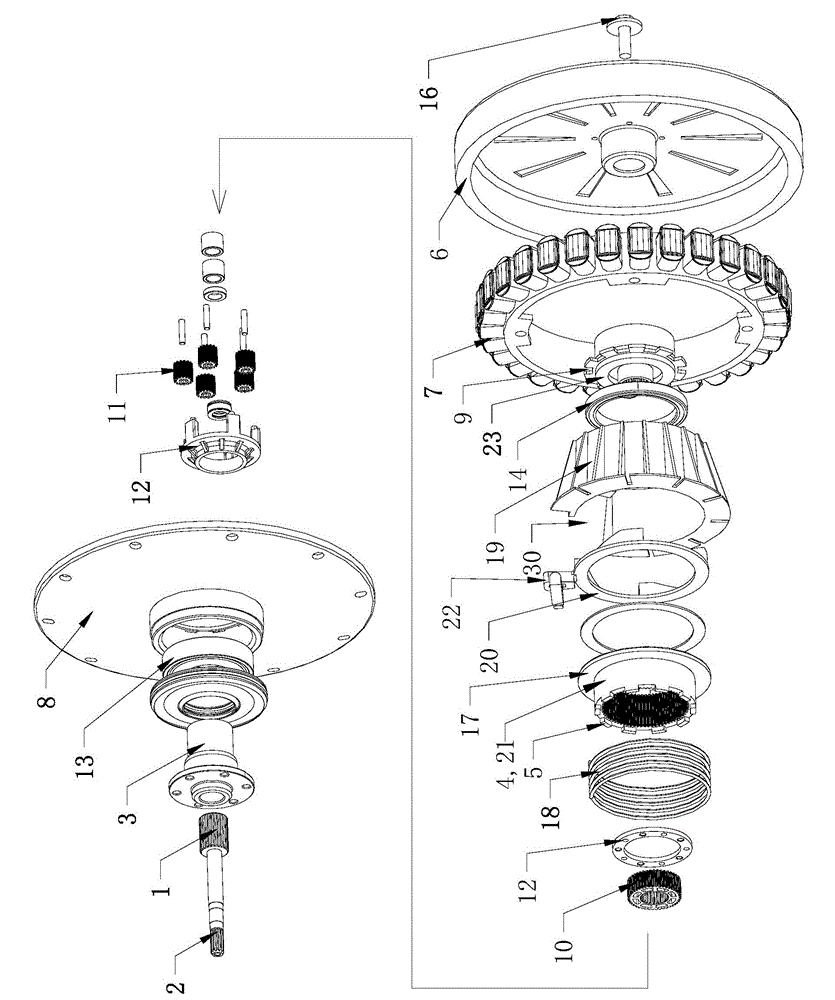

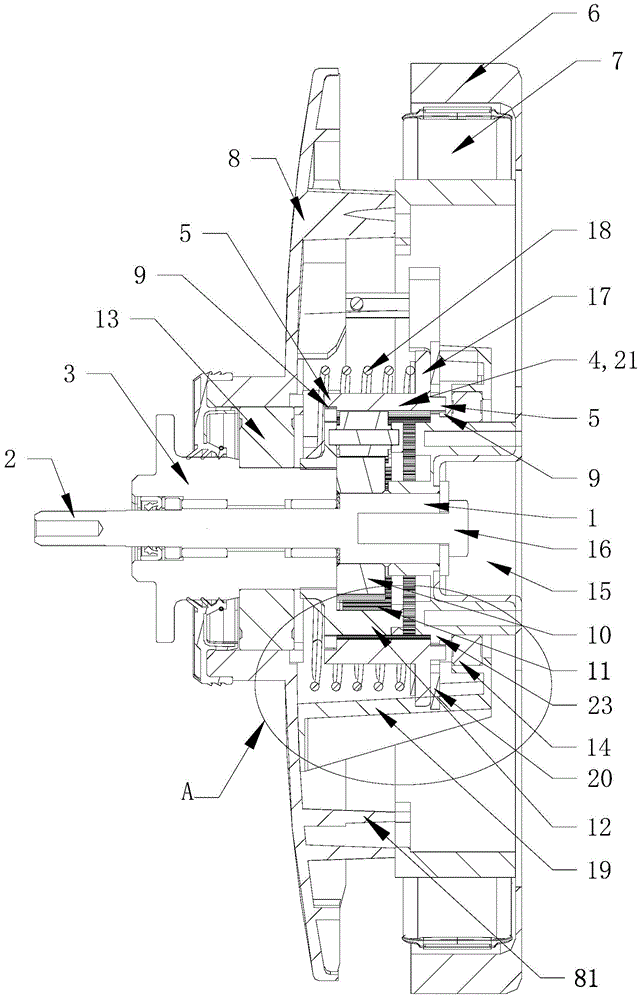

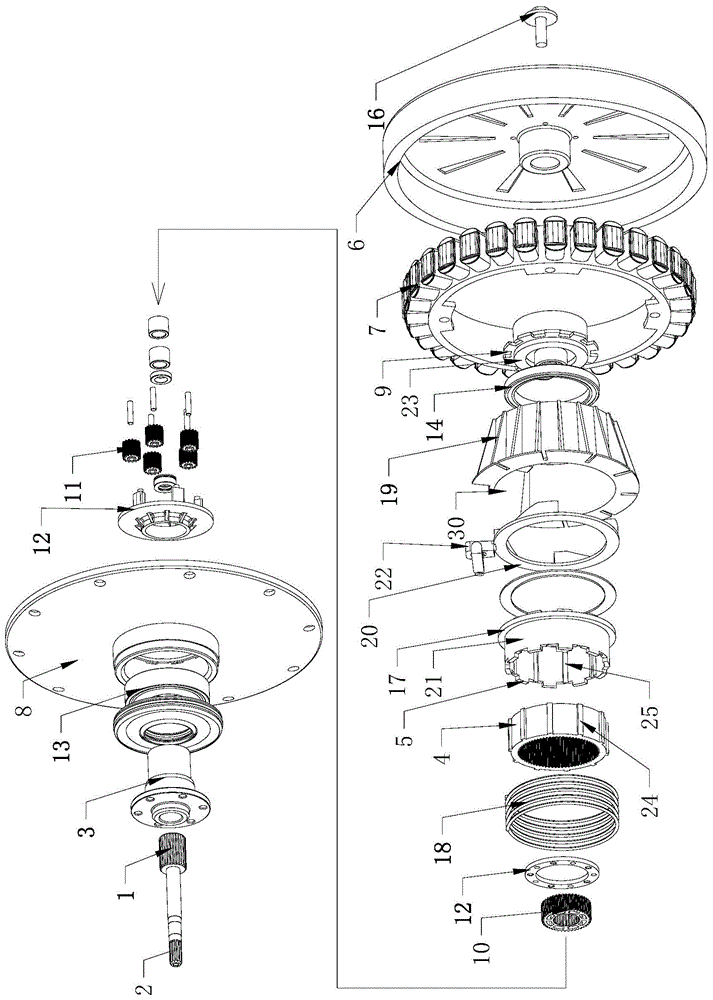

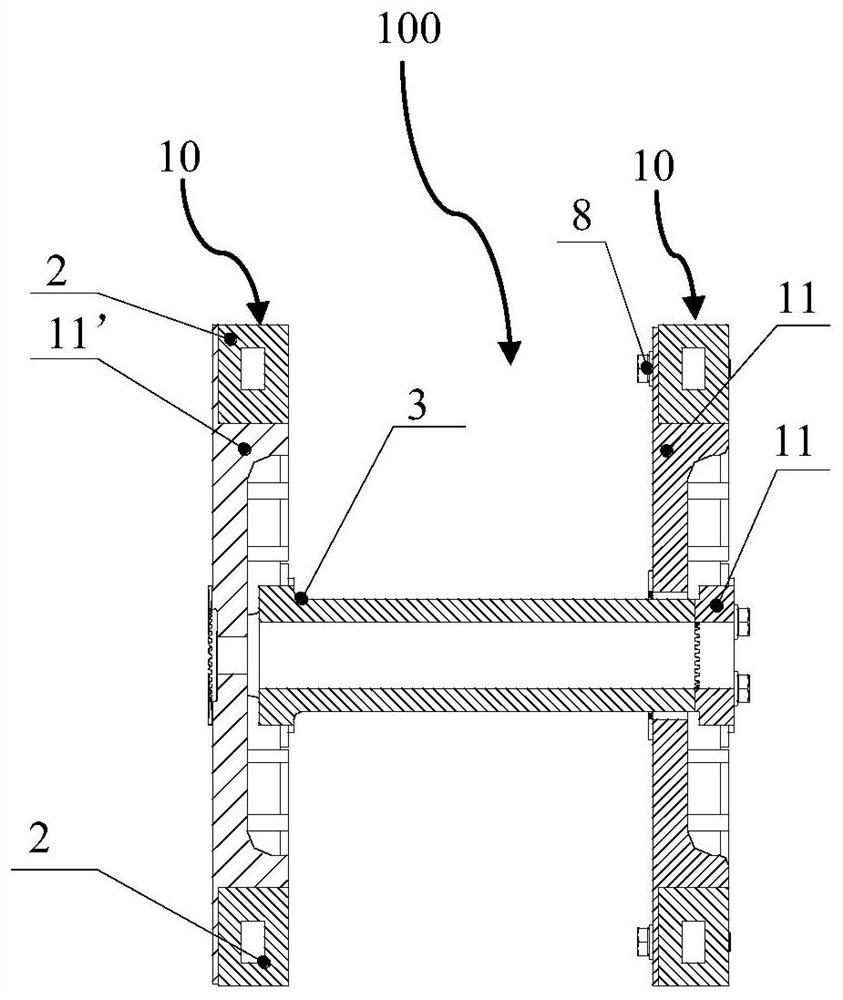

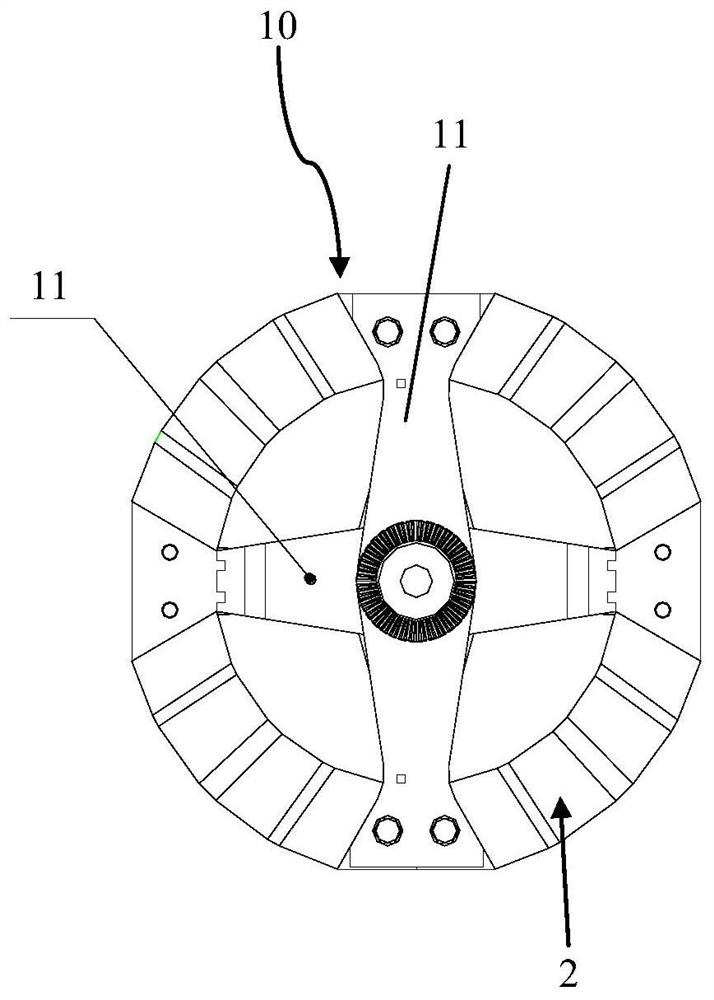

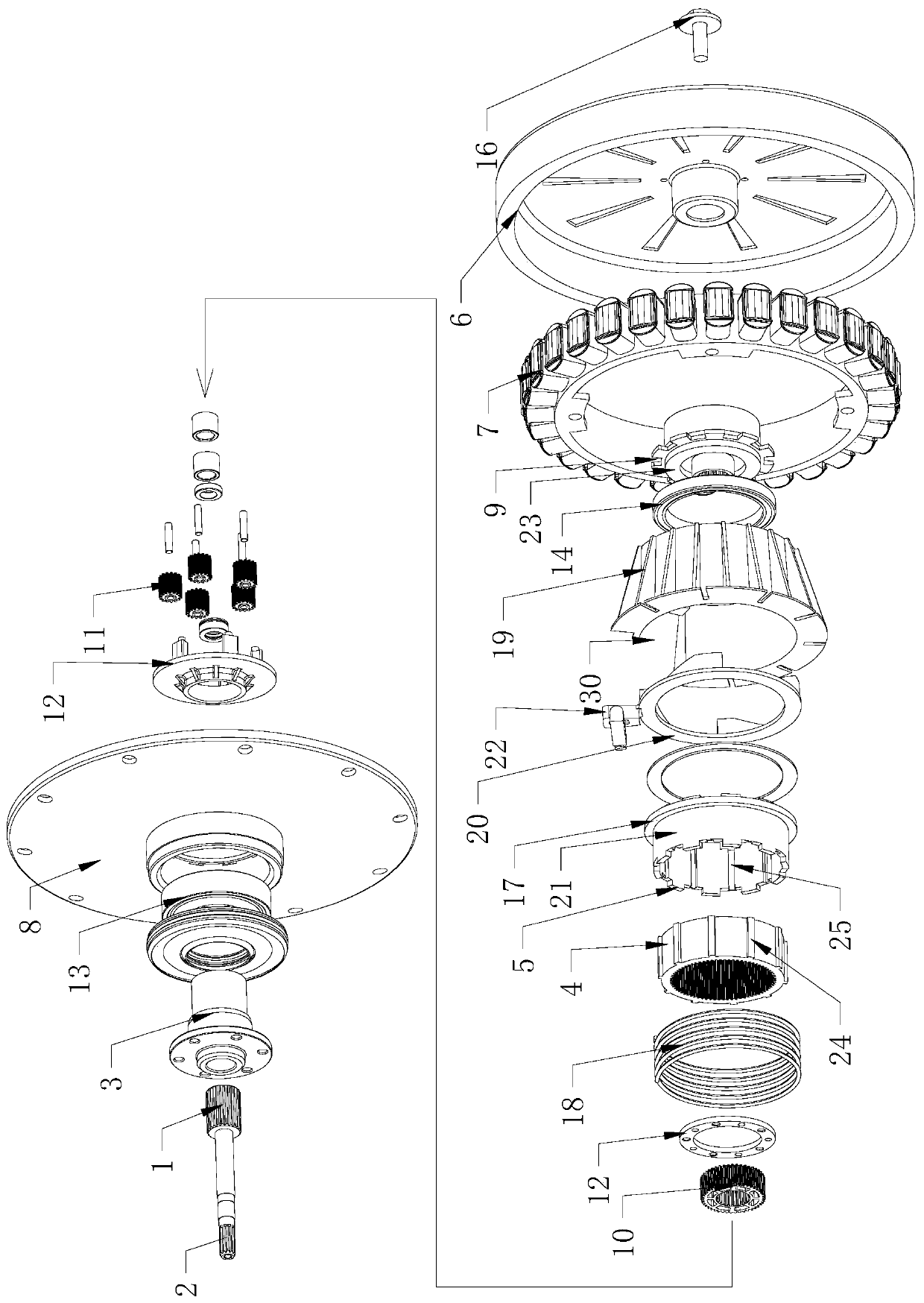

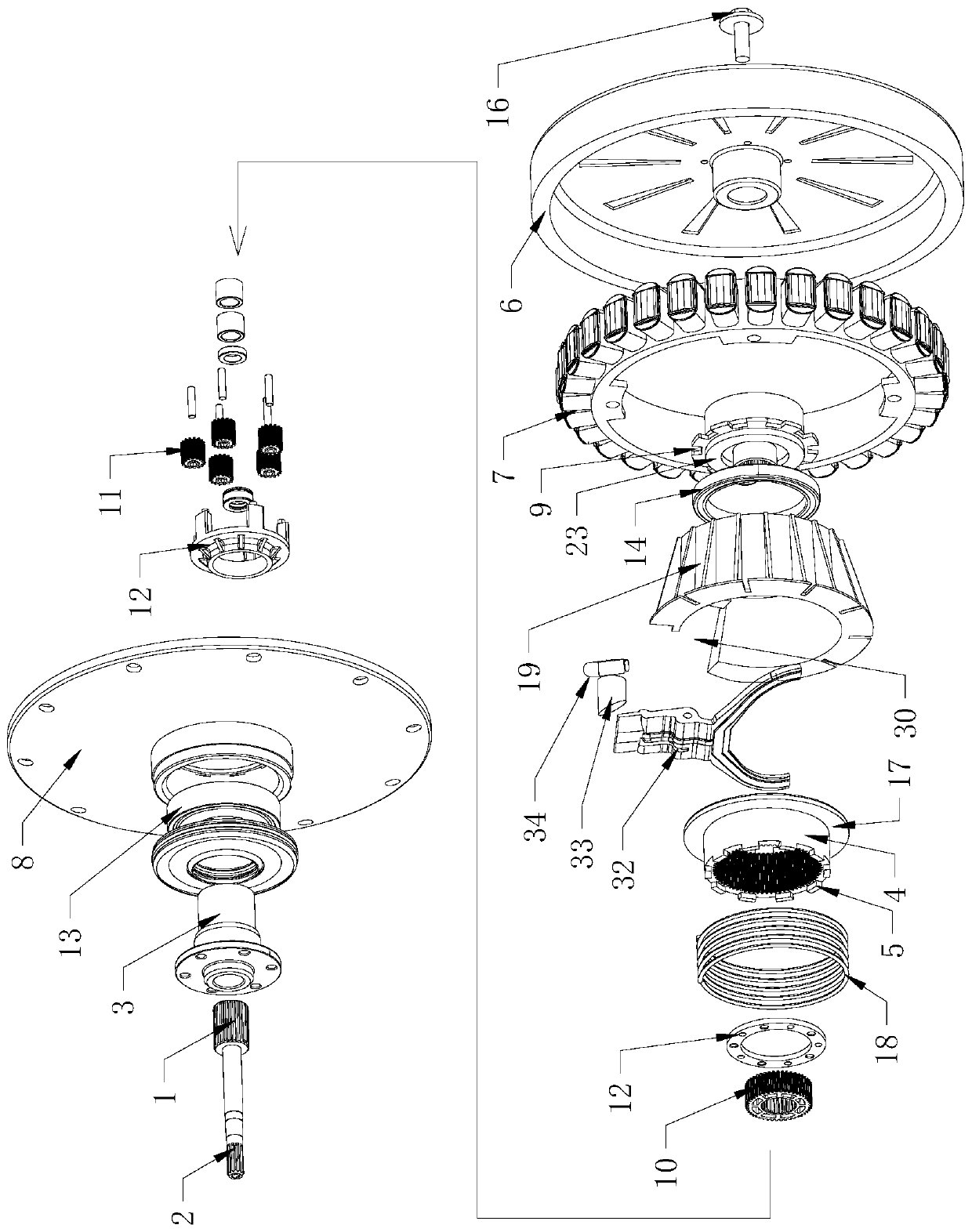

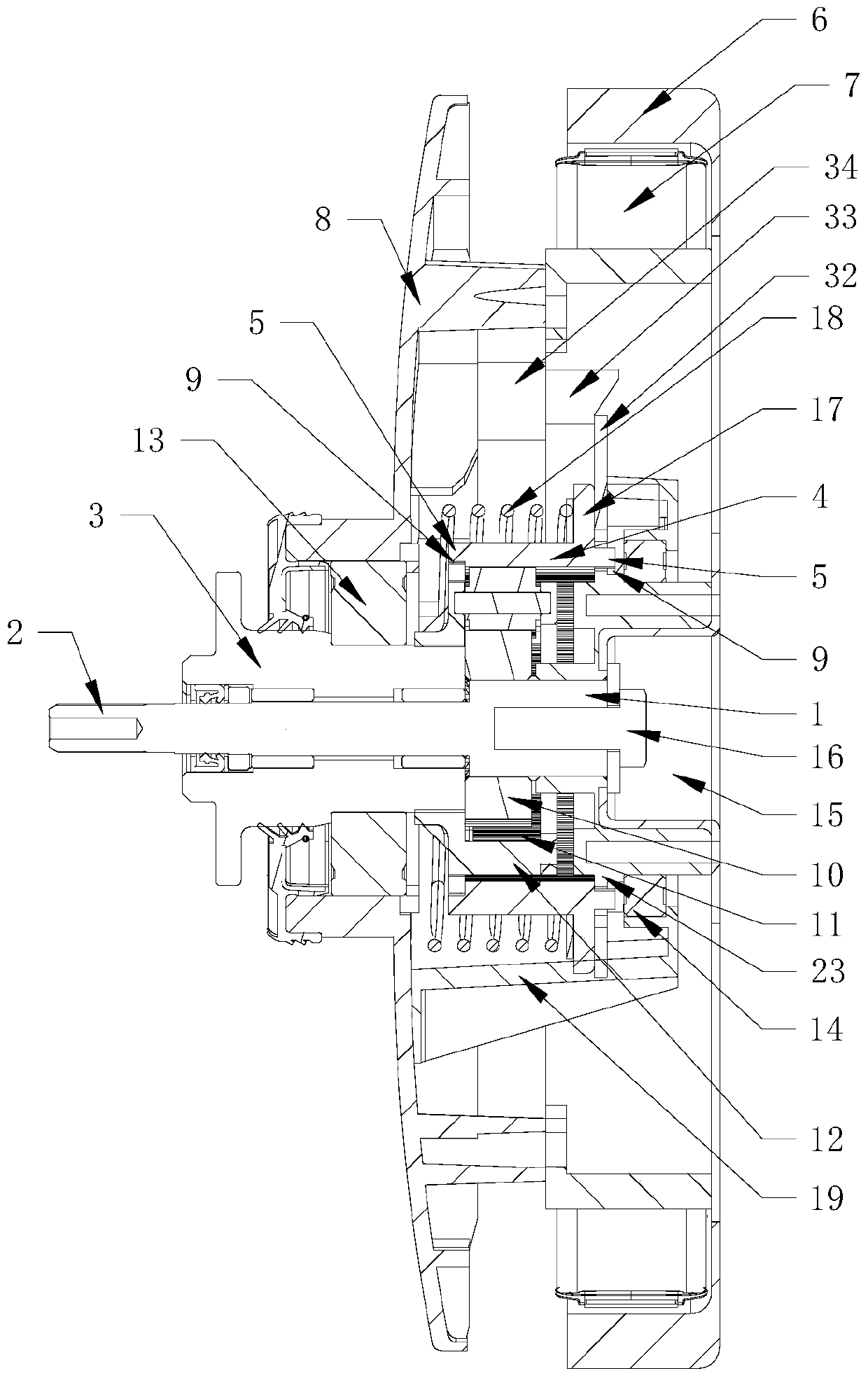

Double-driver washer and reducing clutch therefor

ActiveCN104452169AAxially takes up little spaceImprove performance indicatorsOther washing machinesToothed gearingsPulp and paper industryGear train

The invention relates to the technical field of washers, in particular to a double-driver washer and a reducing clutch therefor. The reducing clutch comprises a dewatering shaft, a pulsator shaft, a mounting plate and an input shaft; the pulsator shaft is concentrically mounted within the dewatering shaft which is hollow; the dewatering shaft is mounted within the mounting plate through a bearing and an oil seal; the input shaft is connected with an external power source. The reducing clutch is characterized in that the input shaft is connected with the dewatering shaft and the pulsator shaft trough a single-reduction mechanism, the single-reduction mechanism comprises an input shaft gear disposed at the top end of the input shaft, the input shaft gear meshes with a planet gear, the planet gear meshes with an inner gear, the inner gear is connected with the pulsator shaft through a transmission disc, an outer gear is provided outside the inner gear, the outer gear is mounted on a planet carrier and meshes with the an external inner gear through an external planet gear. The reducing clutch, which is a different reducing system with double motor wheel systems, and the double-driver washer with the system are provided, small axial space is used, the reducing clutch is suitable for direct drive washers, and overall performance is greatly improved.

Owner:NINGGUO JULONG IND

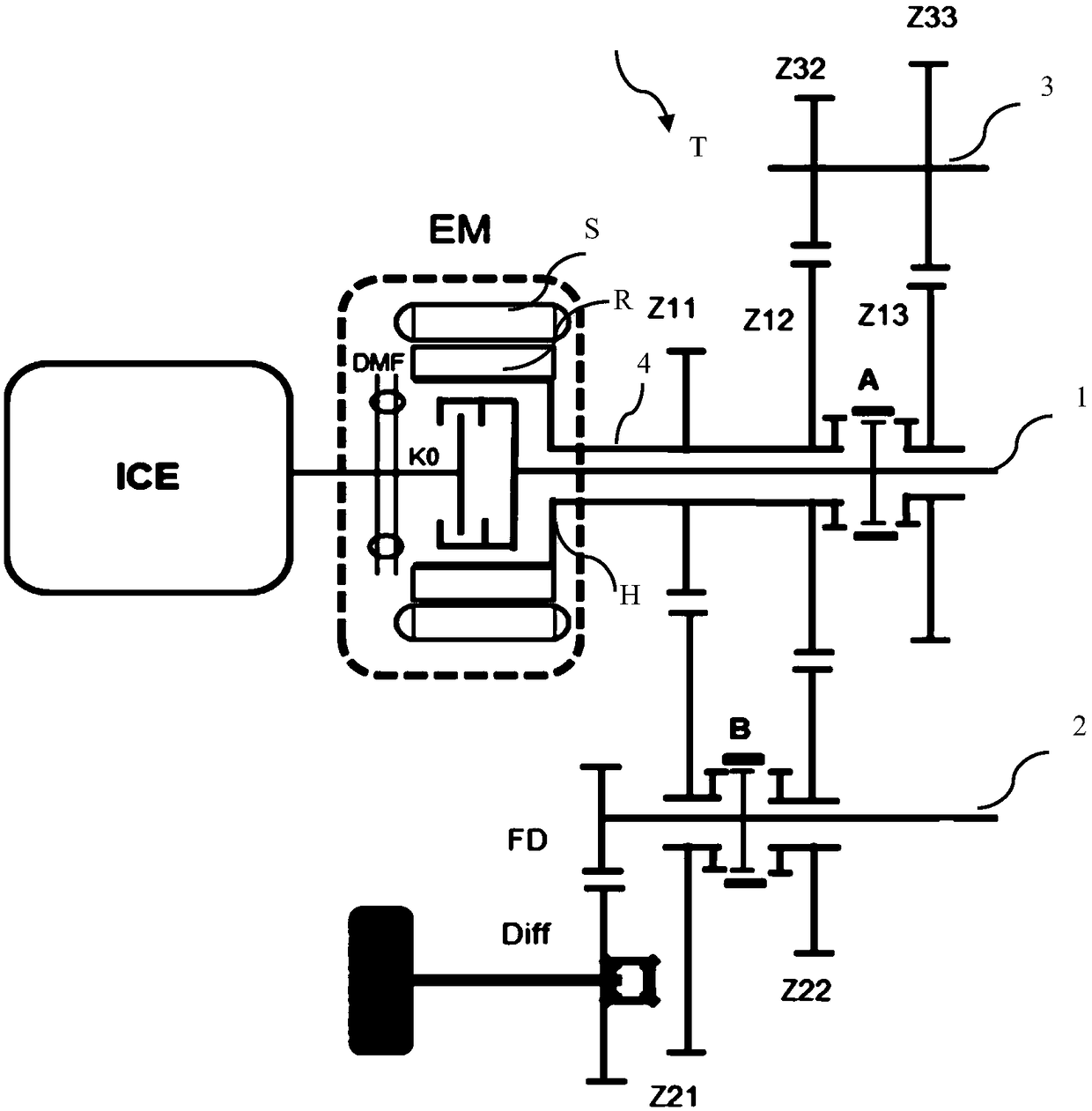

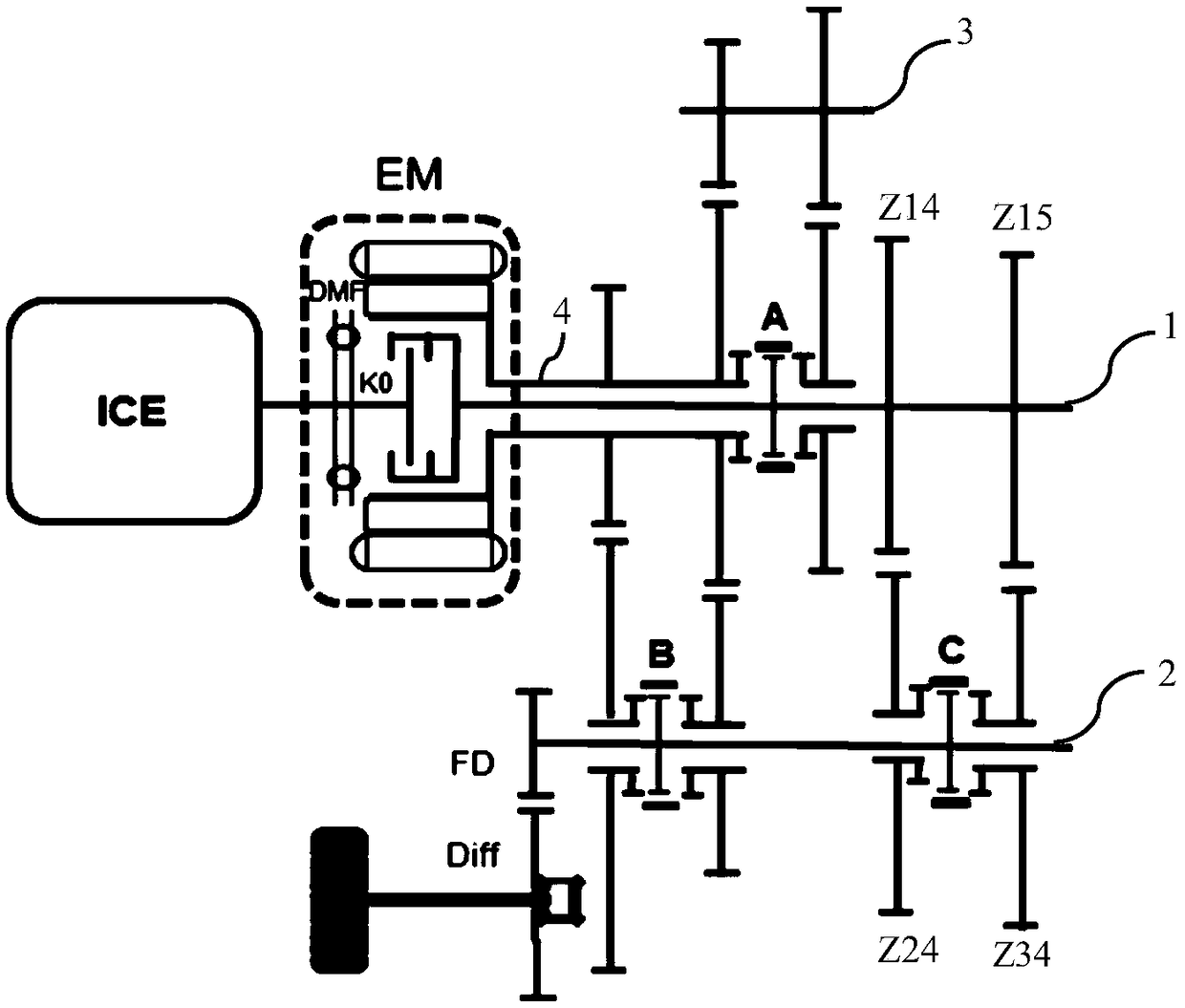

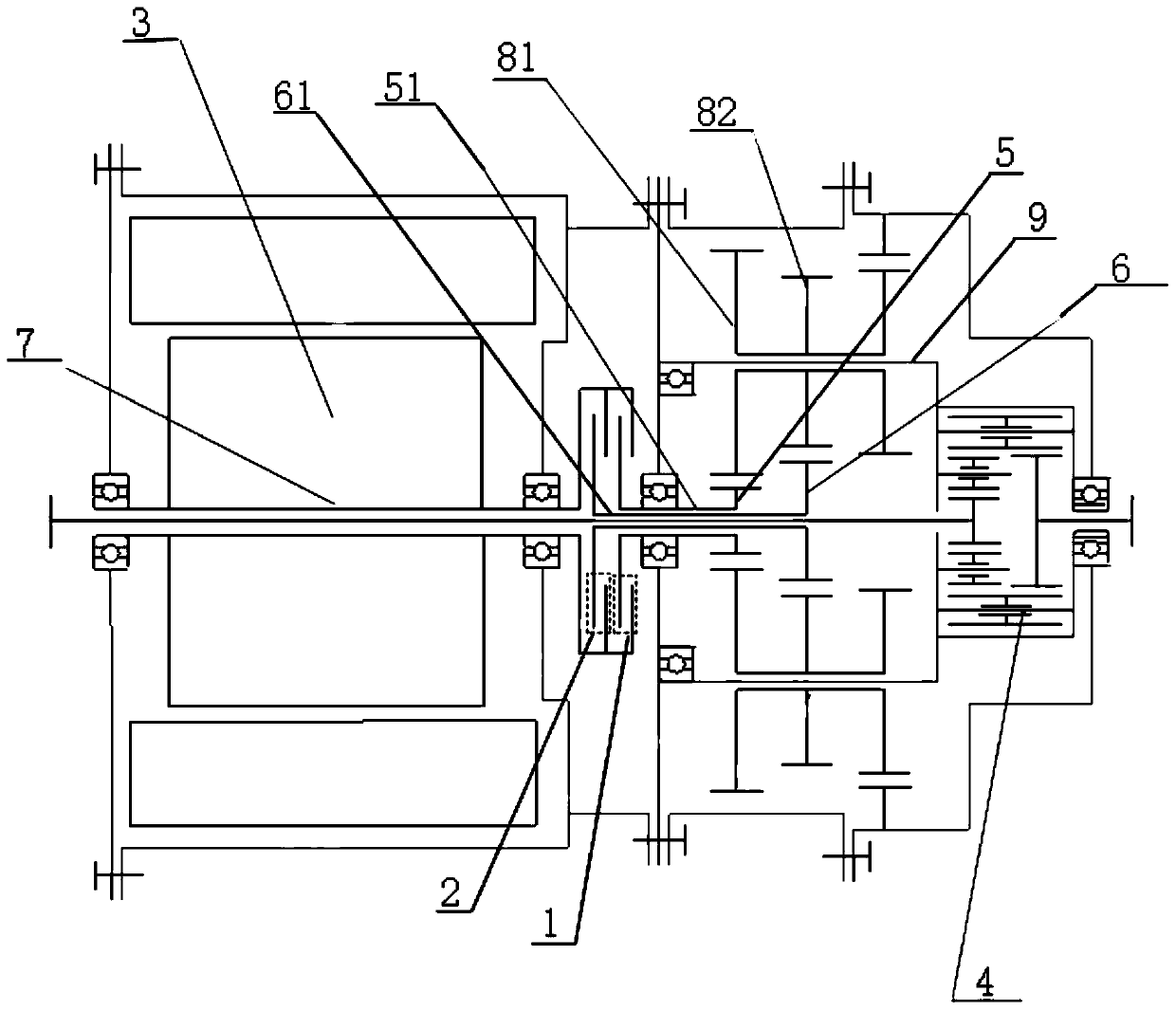

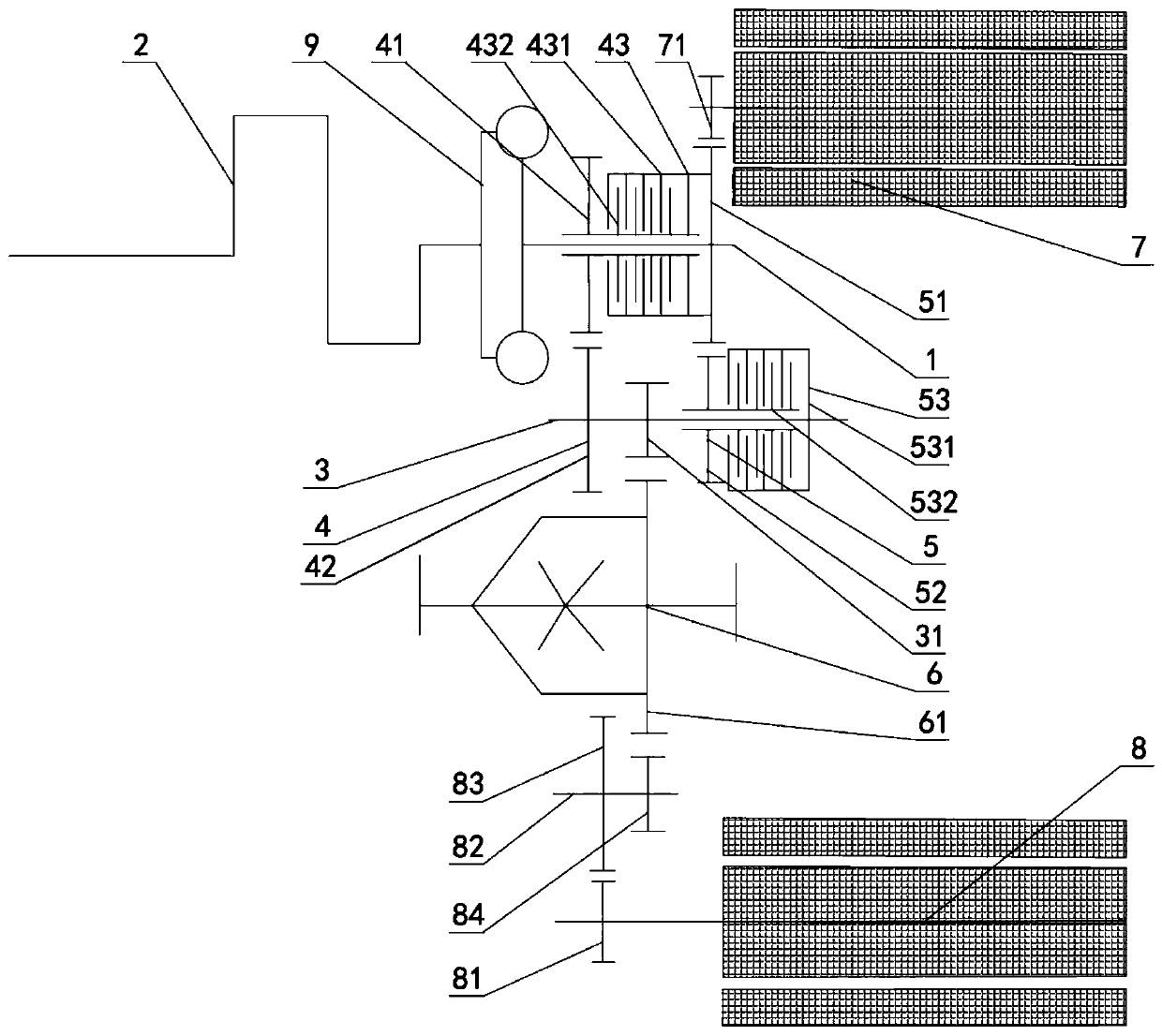

Hybrid power transmission, hybrid power driving system and hybrid power vehicle

InactiveCN108662094AReduce manufacturing costReduce extra spaceHybrid vehiclesToothed gearingsElectric power transmissionTransmitted power

The invention relates to a hybrid power transmission, a hybrid power driving system and a hybrid power vehicle. The hybrid power transmission comprises an input shaft, an intermediate shaft and an output shaft, wherein the intermediate shaft is used for transmitting power between the input shaft and the output shaft; the hybrid power transmission further comprises a first gear, a second gear and athird gear, wherein the first gear, the second gear and the third gear are arranged on the input shaft in a sleeved mode, and the first gear and the second gear are adjacently arranged in the axial direction and rotate synchronously; a first synchronizer is arranged on the input shaft, the first synchronizer is located between the second gear and the third gear and can be connected to the secondgear or the third gear; a fourth gear and a fifth gear are arranged on the intermediate shaft, and the fourth gear and the fifth gear are meshed with the second gear and the third gear respectively; and a sixth gear and a seventh gear are arranged on the output shaft, and the sixth gear and the seventh gear are meshed with the first gear and the second gear respectively.

Owner:SCHAEFFLER TECH AG & CO KG

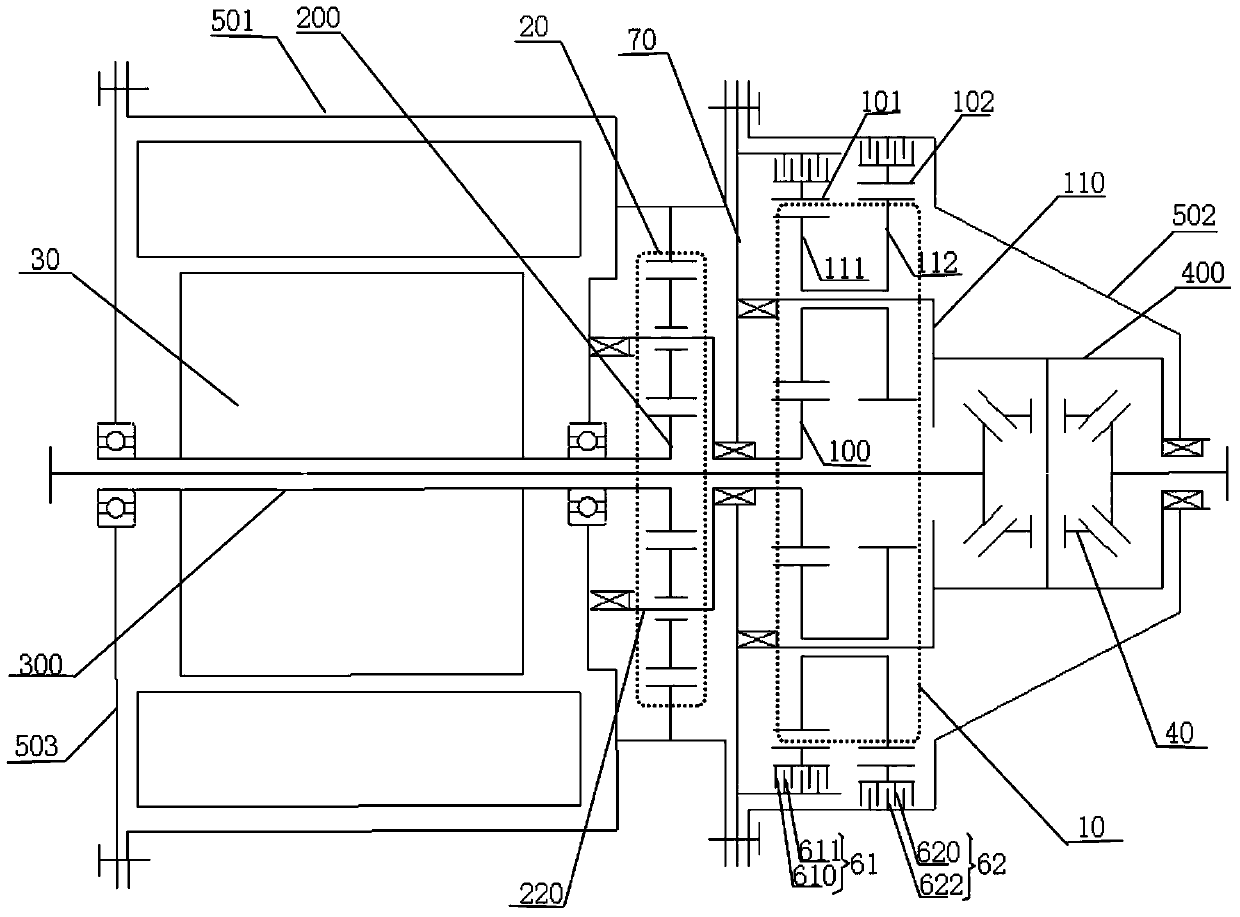

Speed change mechanism as well as driving system and vehicle using same

ActiveCN103775571AAxially takes up little spaceSmall structureToothed gearingsGearing controlEngineeringMechanical engineering

The invention relates to a speed change mechanism as well as a driving system and a vehicle using the same. The speed change mechanism comprises a planet row, wherein the planet row comprises a planet carrier a with planet gear; the planet row further comprises a gear ring which moves in the axial direction and is in constant mesh transmission with the planet gear; the speed change mechanism further comprises a fixing gear and a planet carrier gear which are coaxially arranged with the gear ring and are in mesh transmission with the gear ring; the planet carrier gear is fixedly arranged on the planet carrier; the speed change mechanism further comprises a shifting mechanism for driving the gear ring to move axially so as to enable the gear ring to be separately meshed with the planet gear, the gear ring to be simultaneously meshed with the planet gear and the planet carrier gear, the gear ring to be simultaneously meshed with the planet gear and the fixing gear. The invention provides the speed change mechanism with a small axial occupied space, and the driving system and the vehicle using the speed change mechanism.

Owner:ZHENGZHOU YUTONG BUS CO LTD

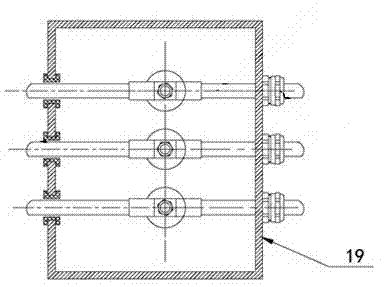

Ultrathin vehicle-mounted magnetic suspension flywheel battery and working method thereof

ActiveCN113422467AAxially takes up little spaceHighly integratedElectric machinesMechanical energy handlingMagnetic bearingElectrical battery

The invention discloses an ultrathin vehicle-mounted magnetic suspension flywheel battery for an electric vehicle, and a working method thereof. A motor bracket, an axial magnetic flux motor, a flywheel, an inner stator of a five-degree-of-freedom magnetic bearing, a coil and a permanent magnet are coaxially arranged in a shell from top to bottom, and the flywheel consists of an upper layer, a middle layer and a lower layer which are continuous; an upper annular groove is formed in the middle of the upper annular layer of the upper flywheel, the axial flux motor is placed in the upper annular groove, and an annular inner groove, a middle annular cavity and a lower annular groove are communicated and jointly used for placing the inner stator, the coil and the permanent magnet of the five-degree-of-freedom magnetic bearing; and the five-degree-of-freedom magnetic bearing comprises an axial magnetic bearing, a repulsion magnetic bearing, a torsion magnetic bearing and a radial spherical magnetic bearing from inside to outside. The mode that magnetic bearings with different properties are reused is adopted, advantage complementation is achieved, the bearing capacity and control precision of magnetic bearing supporting can be improved, the stability of a flywheel is remarkably improved, and the problem that the loss of a control coil is large due to complex working conditions can be effectively solved.

Owner:JIANGSU UNIV

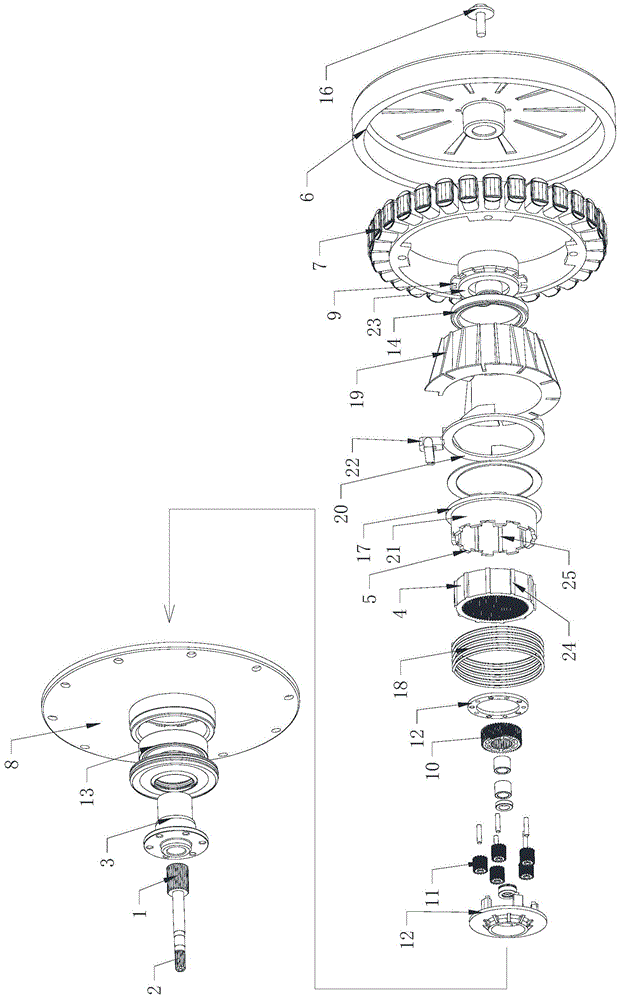

Washing machine deceleration clutch and washing machine

ActiveCN105332239ALower the altitudeReduce volumeClutchesOther washing machinesElectric machineEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the deceleration clutch axially occupies little space; the clutch device comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is an annular gear of the deceleration device; the driving device drives the annular gear to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the annular gear to axially move and the other end is provided with a driving end in transmission connection with a driving motor. The driving device is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and with the compact structure, a modularized structure can be achieved and high component integration degree can be realized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

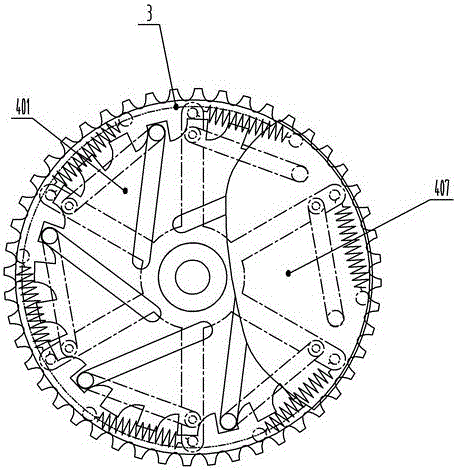

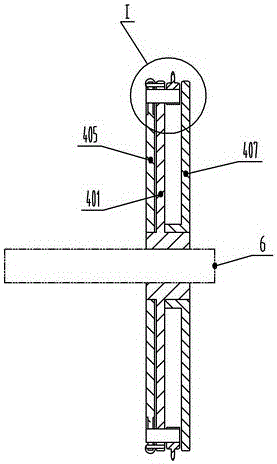

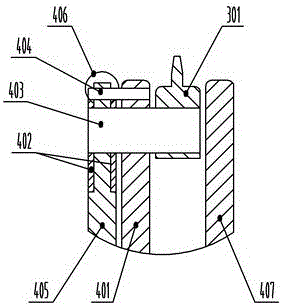

Automatic transmission for bicycle and transmission system

InactiveCN106379479ALower performance requirementsAxially takes up little spaceChain/belt transmissionPull forceAutomatic transmission

The invention particularly relates to an automatic transmission for a bicycle and a transmission system. The automatic transmission comprises a floating tooth disc and a floating tooth disc driver, wherein the floating tooth disc driver comprises a driving disc, force arms, gear teeth, pin shafts, regulating discs, torsion springs and a guide disc, and the gear teeth are pressed into one ends, close to the driving disc, of strip-shaped through holes by the regulating discs under the action of the torsion springs through the force arms; and the floating tooth disc is mounted between the driving disc and the guide disc and comprises a tooth disc body and an inner tooth ring, teeth arranged on the excircle of the tooth disc body are meshed with a chain on the bicycle, and the inner tooth ring is meshed with a tooth ring formed by the gear teeth on the force arms in the floating tooth disc driver. The transmission system comprises the floating tooth disc, the floating tooth disc driver, a single-chip flywheel, the chain, a rear shaft, a middle shaft, a crankshaft, a pedal and a hub, wherein the flywheel is in matched connection with the floating tooth disc, and the floating tooth disc driver is mounted on the middle shaft through a middle hole. The automatic transmission is simple in structure, convenient to manufacture, low in cost, safe, reliable, excellent in performance and high in transmission efficiency.

Owner:朱爱霞

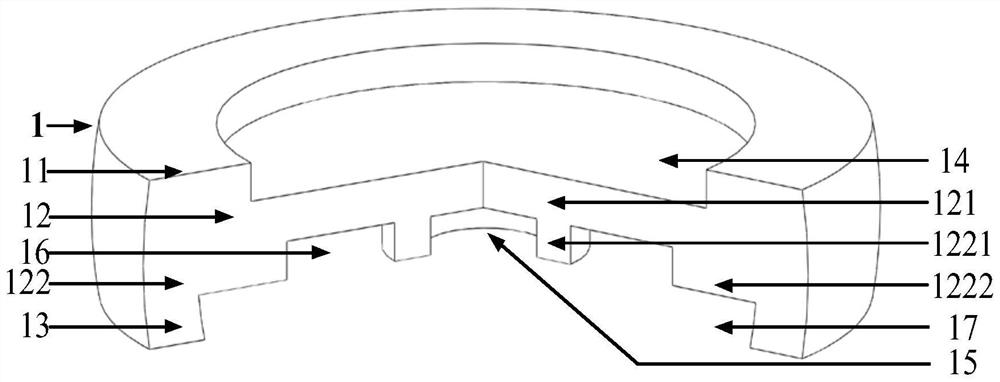

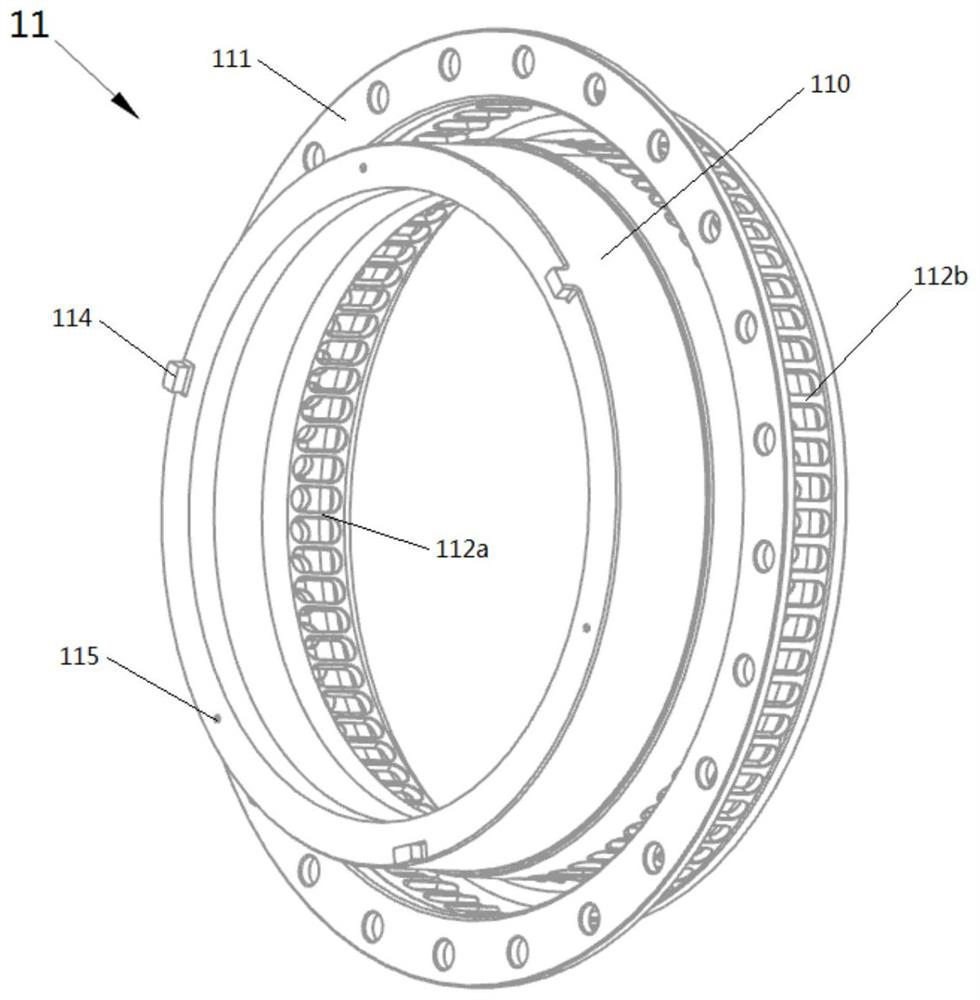

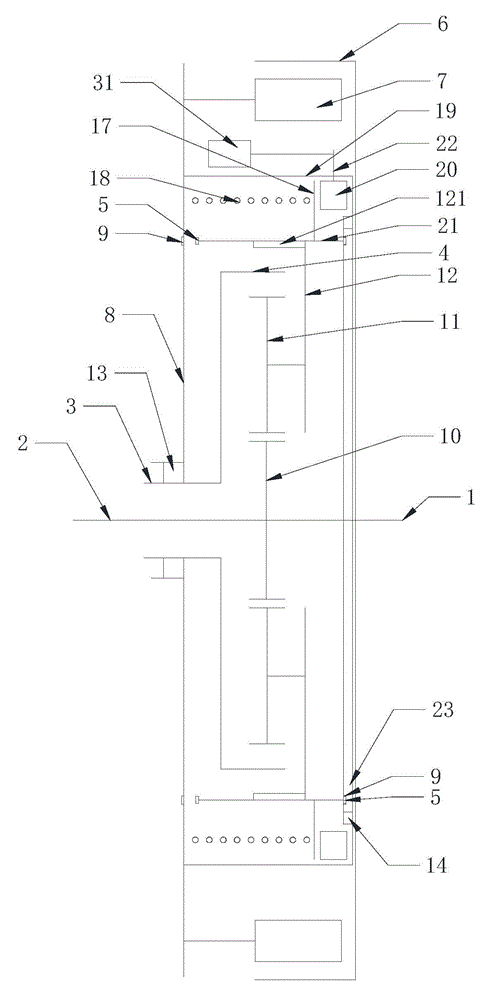

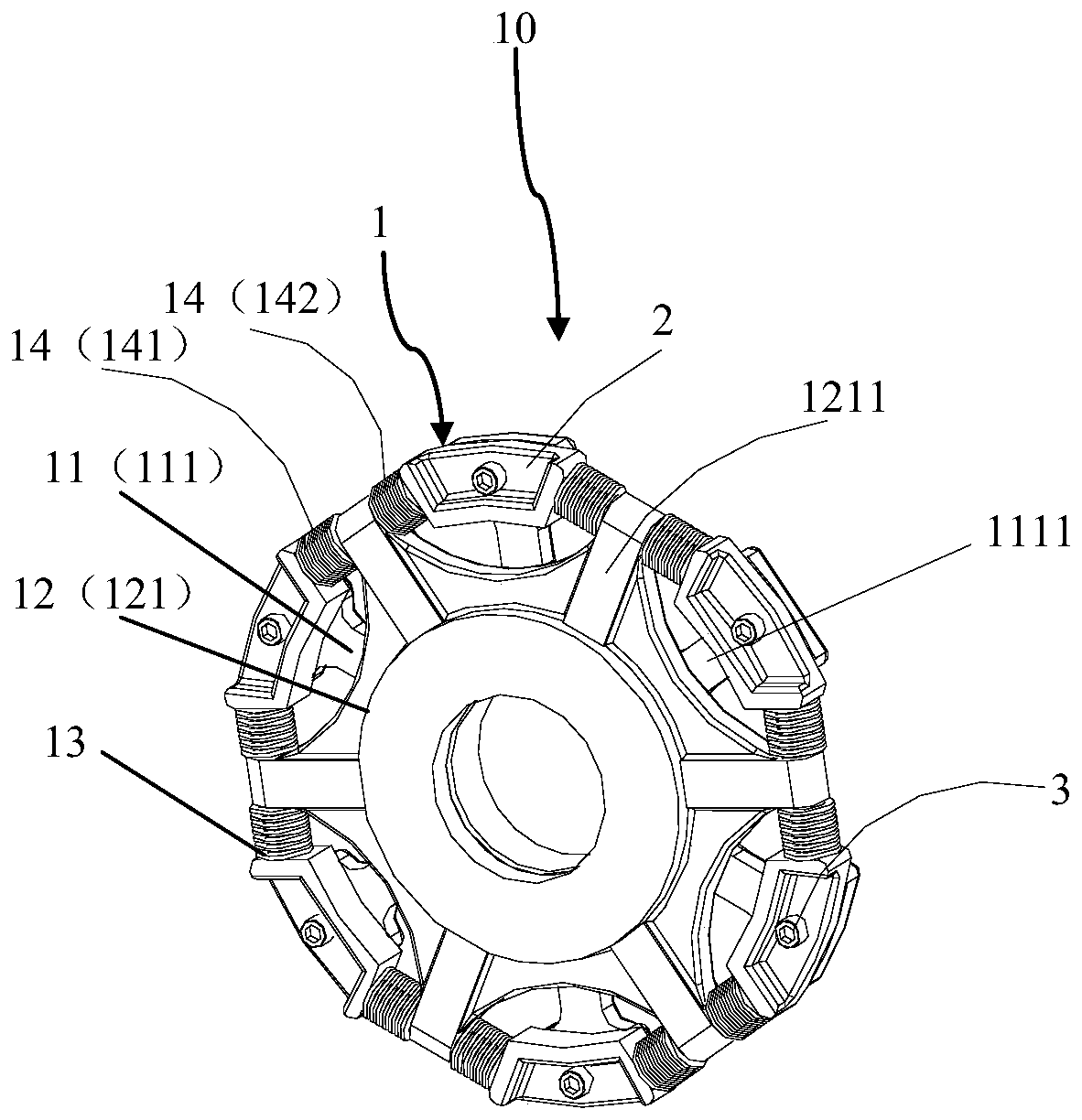

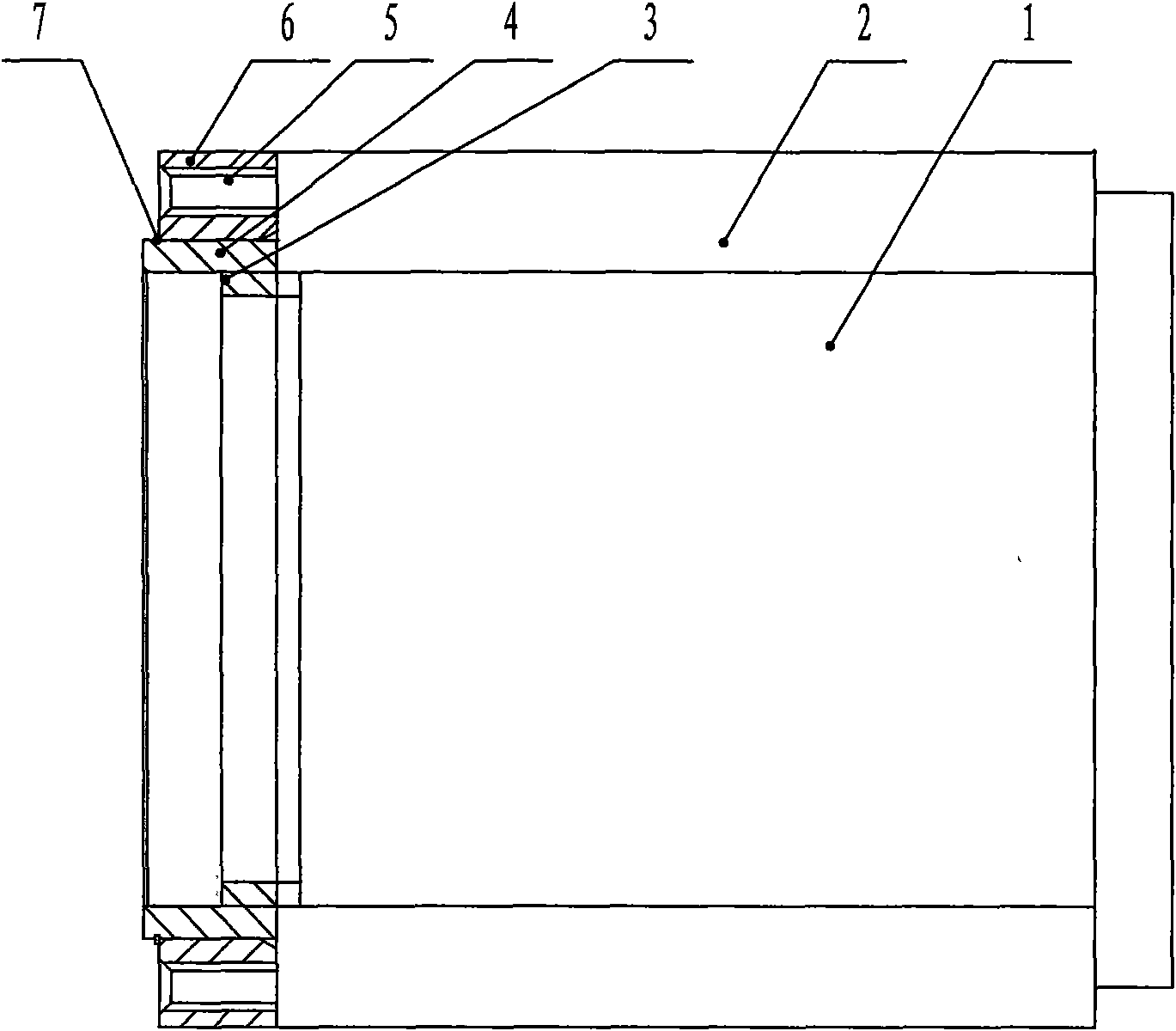

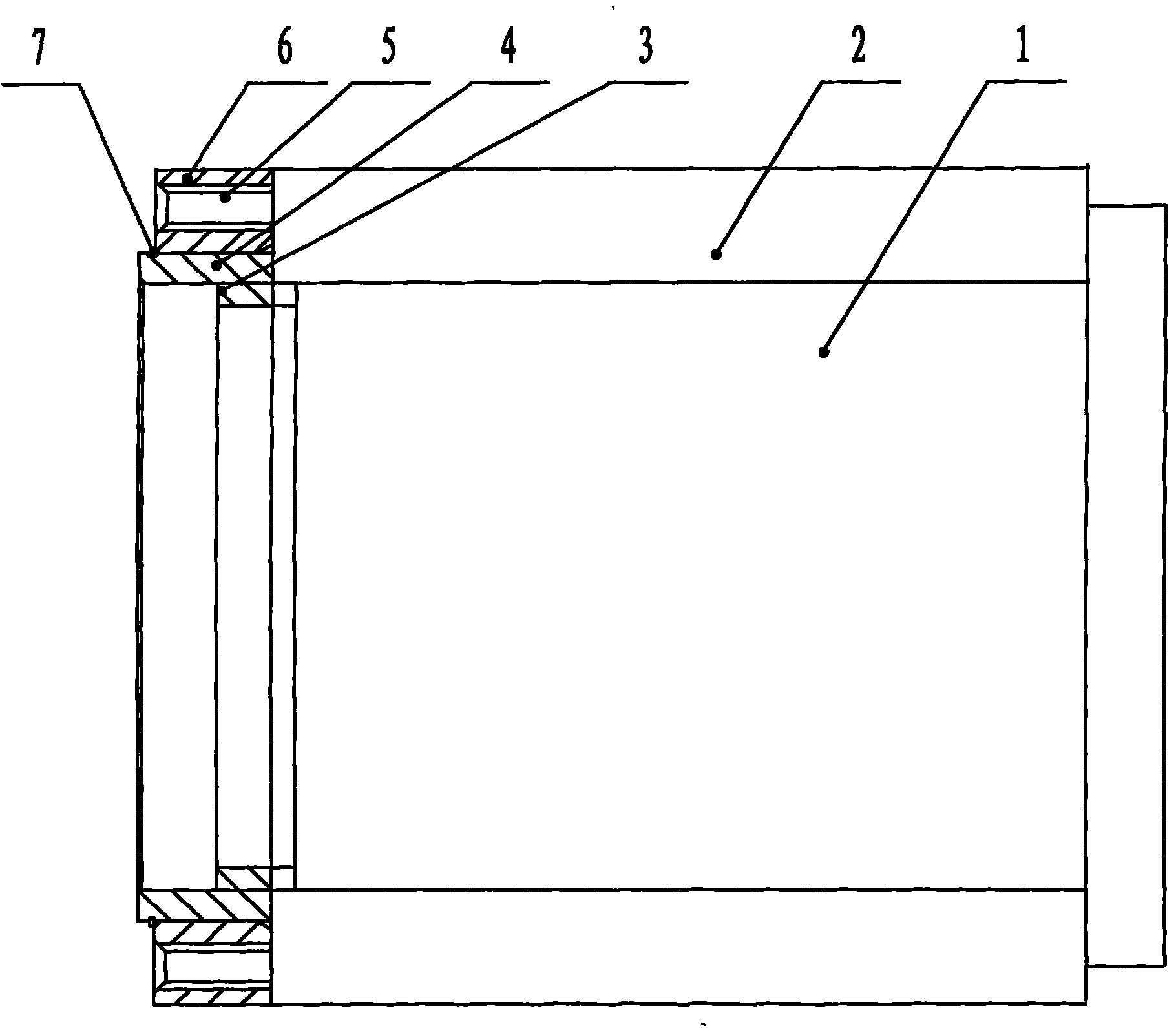

Bearing and bearing outer ring integrated structure

ActiveCN112503096AReduce in quantityReduce processing costsBall bearingsTurbine/propulsion lubricationStructural engineeringFerrule

The invention provides a bearing and a bearing outer ring integrated structure. The bearing comprises a bearing inner ring 12, the bearing outer ring integrated structure 11, a retainer 14 and a plurality of rolling balls 13, wherein the bearing inner ring 12 is a groove-shaped double-half ferrule with the gothic curvature, a circle of drawing groove is formed in the outer circumferential side ofthe bearing inner ring 12, and the retainer 14 is arranged on the outer circumference of the bearing inner ring 12; the bearing outer ring integrated structure 11 is arranged on the outer circumference of the retainer 14, the rolling balls 13 are arranged in an inner cavity formed by the bearing inner ring 12, the retainer 14 and the bearing outer ring integrated structure 11; the bearing outer ring integrated structure 11 comprises a bearing outer ring 110, a mounting edge 111, a first-section squirrel cage strip 112a, a second-section squirrel cage strip 112b, a supporting web 113, a boss 114 and a temperature measuring hole 115, wherein one end of the first-section squirrel cage strip 112a is connected to the bearing outer ring 110, and the other end of the first-section squirrel cage strip 112a is connected to the lower end of the supporting web 113; and one end of the second-section squirrel cage strip 112b is connected to the upper end of the supporting web 113.

Owner:AECC SICHUAN GAS TURBINE RES INST

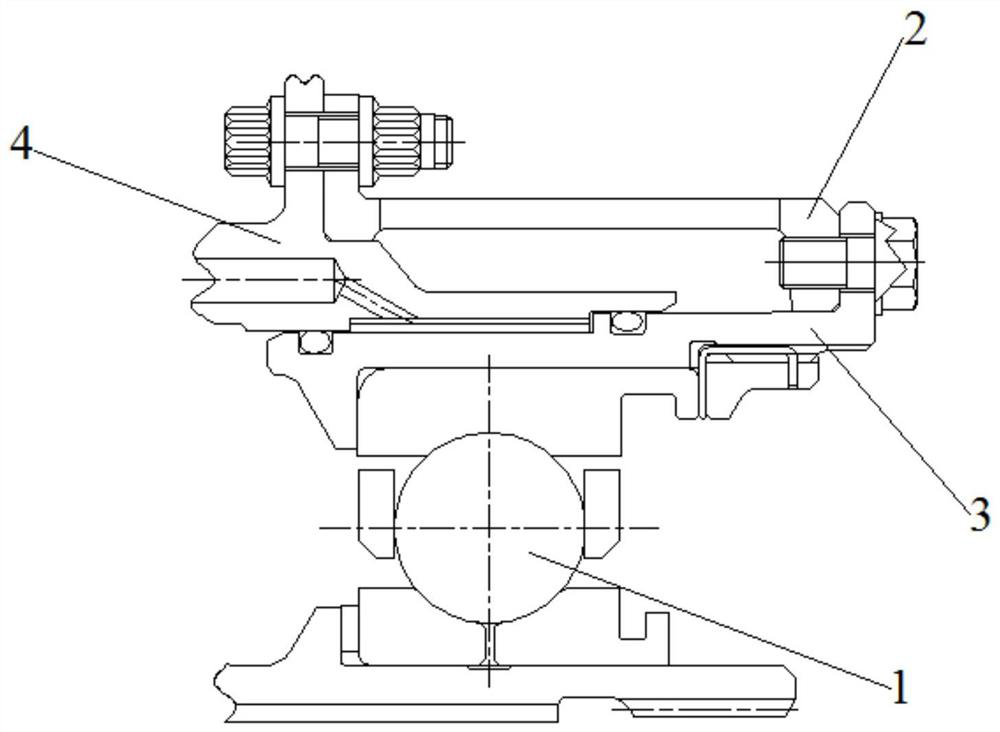

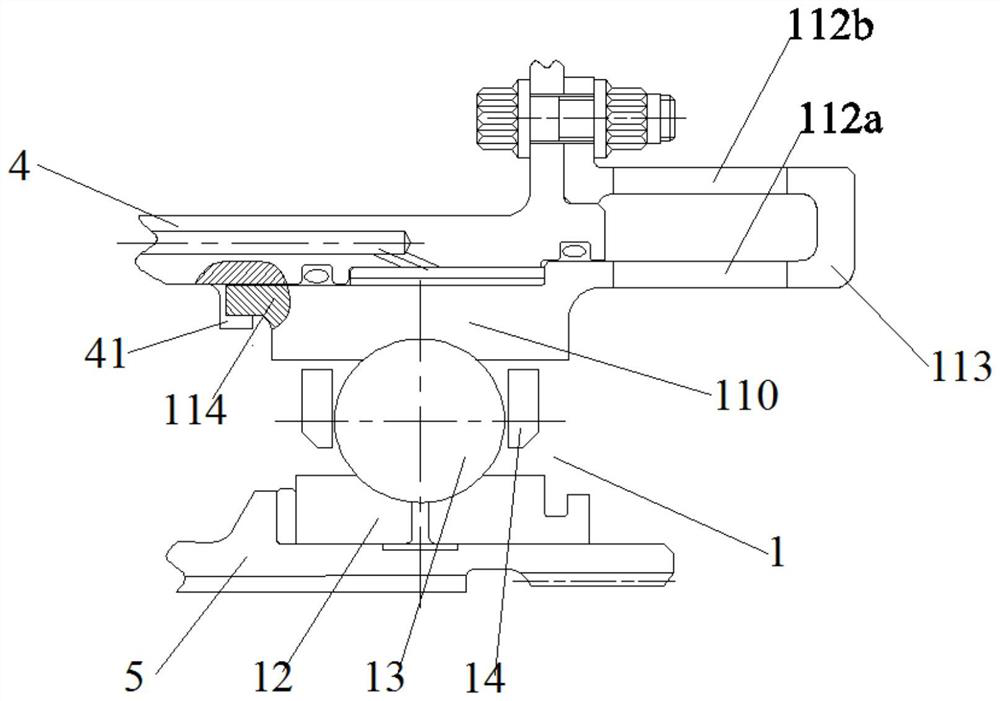

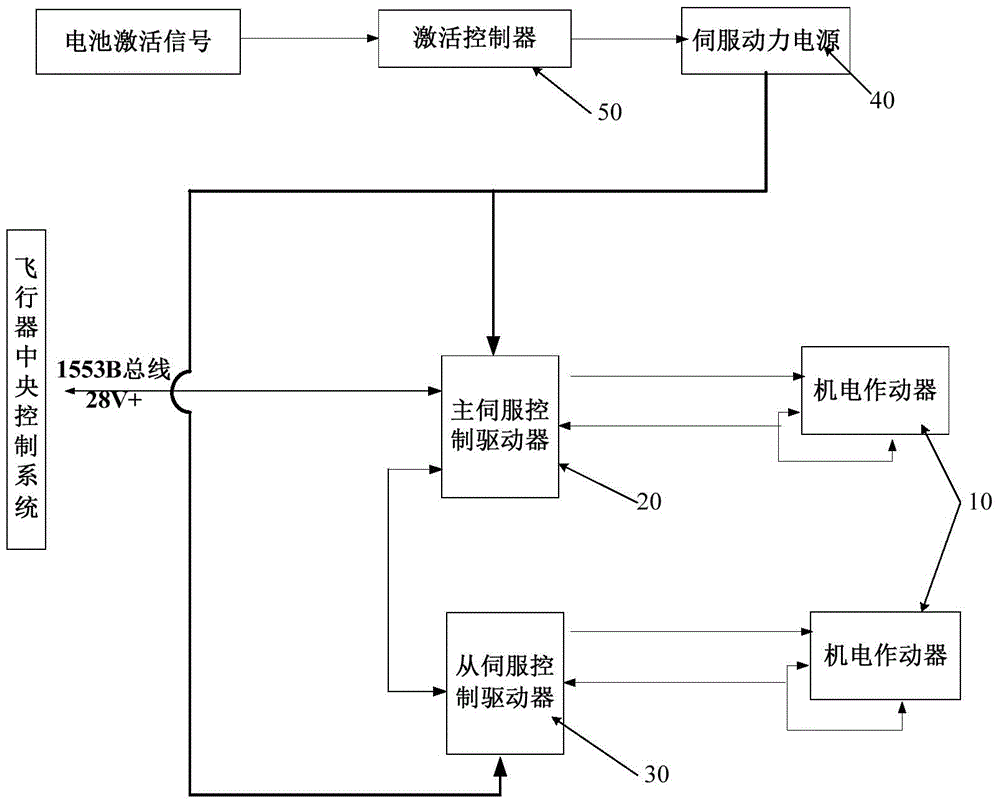

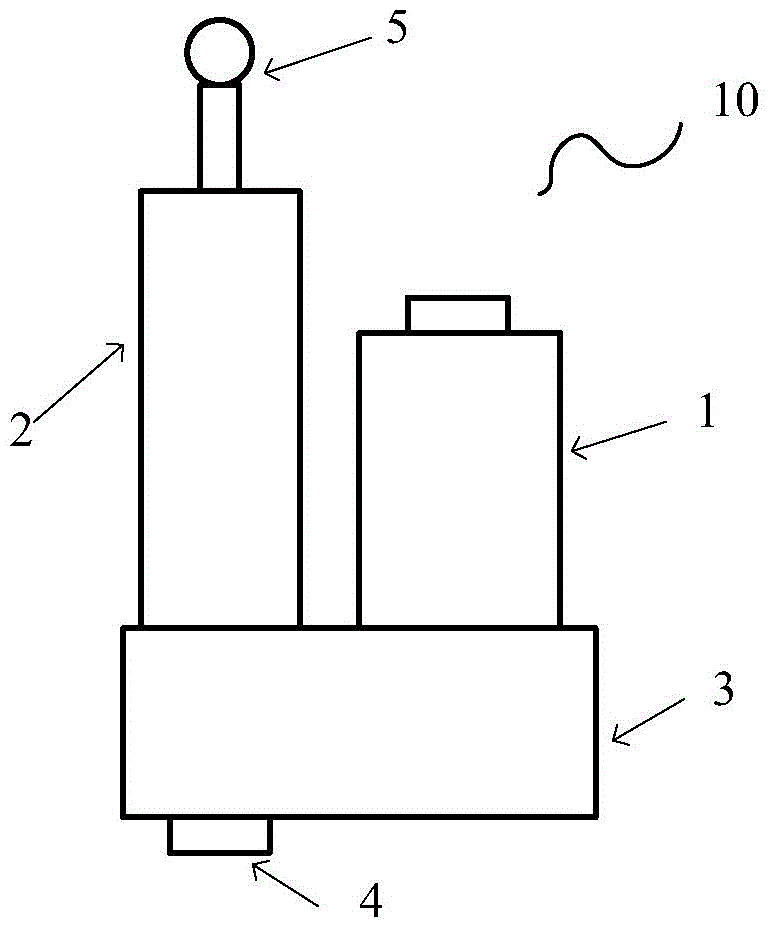

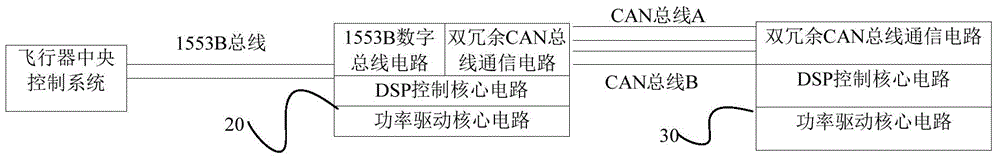

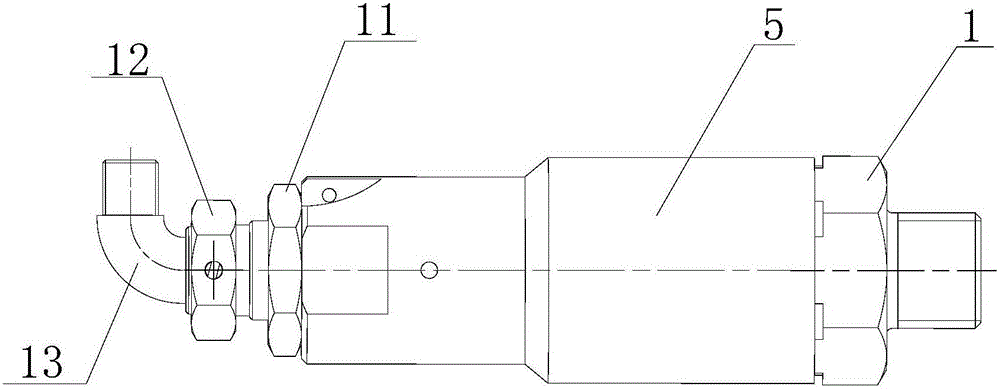

Thrust vector controlled electromechanical servo system

ActiveCN104698984AAxially takes up little spaceSmall footprintVehicle position/course/altitude controlNumerical controlGear transmissionElectromechanical actuator

The invention provides a thrust vector controlled electromechanical servo system. The provided thrust vector controlled electromechanical servo system comprises two electromechanical actuators, one master servo control driver, one slave servo control driver, and one servo power supply for supplying the power, wherein the master servo control driver and the slave servo control driver respectively drive and control one electromechanical actuator. The electromechanical actuators are parallel electromechanical actuators. The parallel electromechanical actuators comprise servo motors, ball screw transmission mechanisms, and gear transmission mechanisms which are drivingly connected with the servo motors and the ball screw transmission mechanisms. The ball screw transmission mechanisms are in parallel with the servo motors. By employing the parallel electromechanical actuators, i.e., allowing the ball screw transmission mechanisms to be in parallel with the servo motors, the axial space occupation of the whole electromechanical servo system is reduced effectively, accordingly meeting the requirements of design and usage at the greatest extent under the condition of seriously limiting the axial installation dimension.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

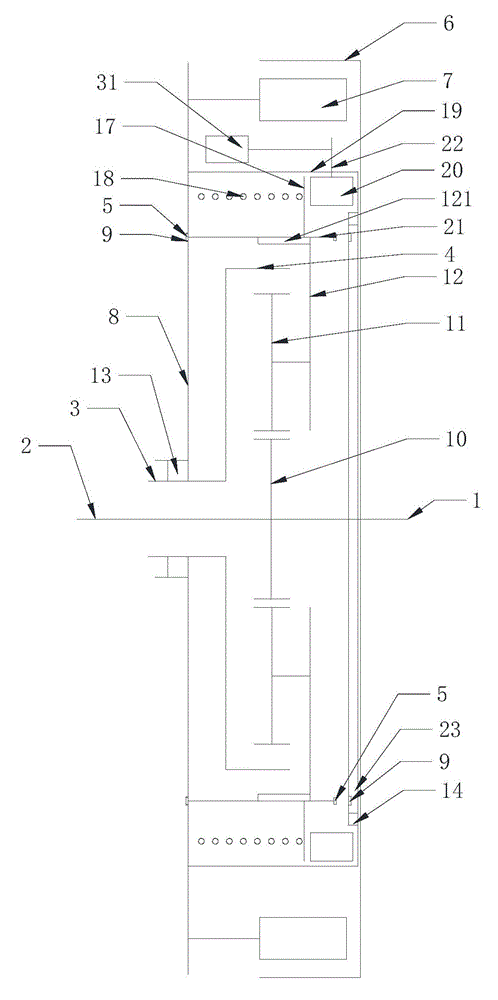

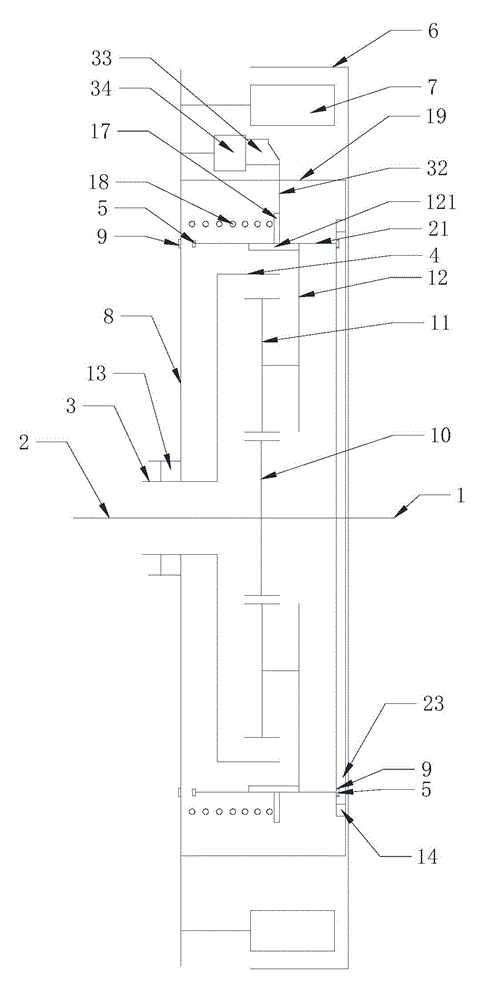

Vertical tractor and screw elevator using vertical tractor

The invention relates to a vertical tractor and a screw elevator using the vertical tractor. In the vertical tractor, a brake at the upper end of a rotating shaft comprises a friction disc which is assembled on the rotating shaft in a rotating stop manner and a brake plate which is positioned above the friction disc; an armature is arranged below the friction disc; a positioning shaft shoulder with an upward step surface is arranged on the rotating shaft; when an electromagnetic coil is powered off, the armature pushes the friction disc to compress the brake plate under the action of a brake spring, and a gap is reserved between the armature and the upper end surface of an upper end cover; when the electromagnetic coil is powered on, the armature moves downwards to tightly adhere to the upper end surface of the upper end cover under the action of electromagnetic force, and simultaneously, the friction disc moves downwards and is stopped above the positioning shaft shoulder under the action of gravity; and a gap is reserved between each of the upper side and the lower side of the friction disc and the brake plate as well as the armature. According to the vertical tractor and the screw elevator using the vertical tractor, limited operation of the friction disc is realized; in a release state of the brake, an air gap on the upper side and the lower side of the friction disc can beensured; and the problem that noises are easily produced when the friction disc rotates to rub the brake plate or the armature is solved.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

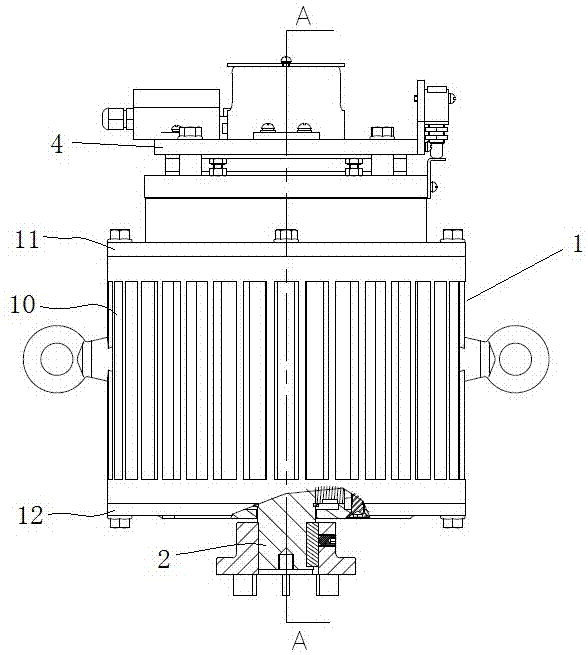

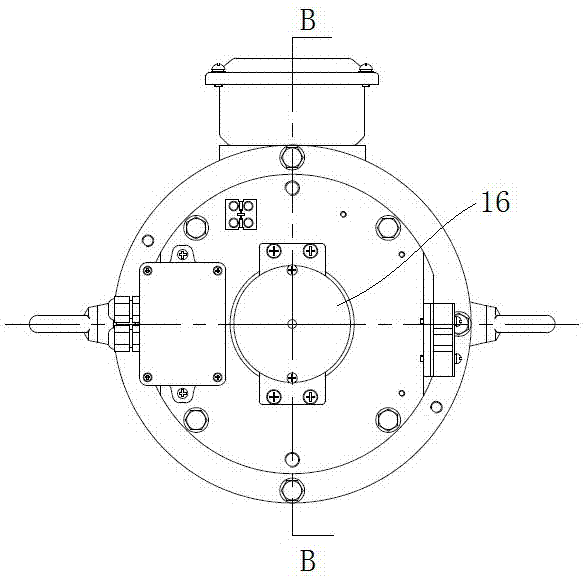

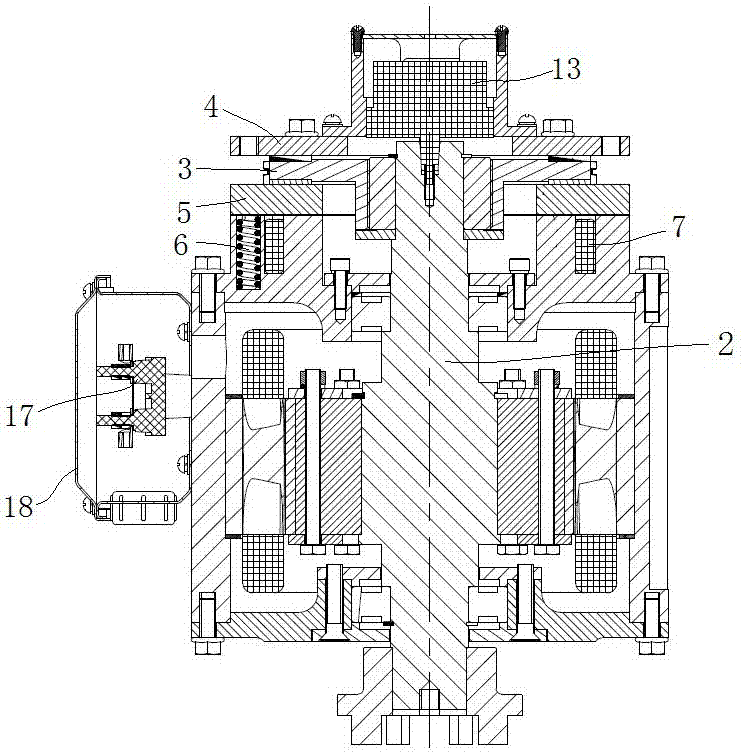

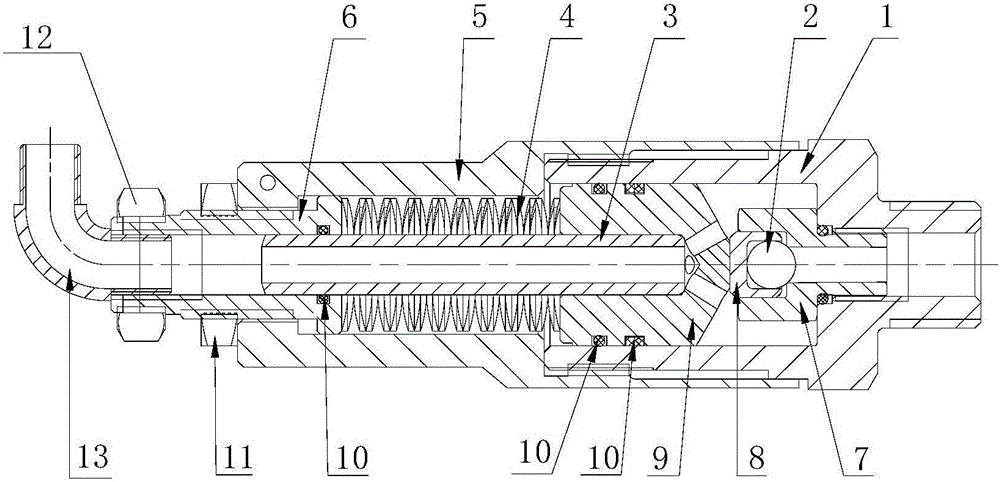

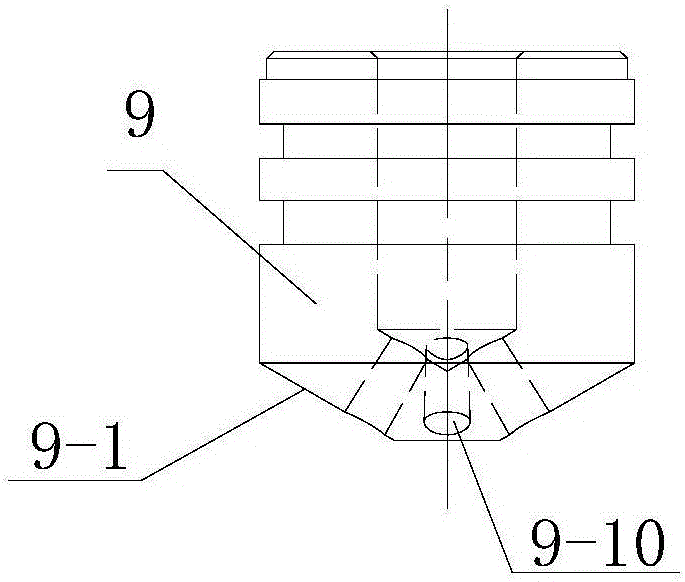

High-pressure liquid collection type pressure regulating overflow safety valve

ActiveCN105090578AStrong enoughRigid enoughEqualizing valvesSafety valvesWorking environmentEngineering

The invention relates to a high-pressure liquid collection type pressure regulating overflow safety valve. The high-pressure liquid collection type pressure regulating overflow safety valve comprises a valve body, a valve cover and a valve core seat, wherein a valve core locating sleeve is assembled in a locating sleeve mounting hole of the valve core seat; a flow guide hole connected with a valve cavity is formed in the valve core seat; a valve core is embedded in the valve core locating sleeve; a valve rod seat is arranged in the valve cavity, and an overflow hole is formed in a conical surface, which is in contact with the valve core locating sleeve, of the valve rod seat; and a hollow valve rod connected with the overflow hole is inserted and arranged in the valve rod seat, a belleville spring is arranged on the hollow valve rod in a sleeved manner, a hollow adjusting screw is arranged in a hollow screw hole of the valve cover in a threaded manner, and a locknut is assembled on the extended adjusting screw. The high-pressure liquid collection type pressure regulating overflow safety valve is capable of guiding, concentratedly collecting and directionally discharging overflowed liquid arbitrarily discharged in the past in a high-pressure liquid collection type pressure regulating overflow manner, thereby improving working environment conditions of a site. The pretightening force of the spring is changed by the adjusting screw in a certain pressure range so as to enable opening pressure to have adjustability. The high-pressure liquid collection type pressure regulating overflow safety valve also has the advantages of simple and compact structure, convenience in disassembly, long service life and the like.

Owner:TIANJIN HAISHENG PUMP MAKING

Washing machine deceleration clutch and washing machine

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and is in a connection with the annular gear in way of being capable of sliding relative to the annular gear but incapable of rotating relative to the same; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one clutch press plate coaxially arranged with the clutch shaft sleeve; and the clutch press plate can circumferentially rotate to drive the clutch shaft sleeve to axially move. The deceleration clutch is simply structured and axially occupies small space; and overall height of the deceleration height can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Liquid-cooling speed-regulating magnetic clutch for ship

PendingCN112271905ANo spillsGood vibration dampingPermanent-magnet clutches/brakesStructural associationElectrical conductorDrive shaft

The invention discloses a liquid-cooling speed-regulating magnetic clutch for a ship, and relates to a magnetic clutch. The problems that an existing water-cooled magnetic clutch is poor in compensation performance, poor in vibration reduction performance and large in axial occupied space during non-contact torque transmission are solved. The cover shell is fixed to the side wall of a supporting plate, the permanent magnet disc assembly and the conductor disc assembly are both arranged in the cover shell, the permanent magnet disc assembly is arranged in the conductor disc assembly, the transmission shaft penetrates through the center of the support and enters the cover shell, the transmission shaft is sleeved with one permanent magnet disc, and the transmission shaft between an inner ringof the support and the transmission shaft is sleeved with a supporting bearing. A sleeve is connected to an inner ring of the support, the supporting bearing is installed between the transmission shaft and the sleeve, an air gap adjusting mechanism is used for adjusting an air gap between the permanent magnet disc assembly and the conductor disc assembly to achieve separation and reunion and adjust the rotating speed of the load end, and the inner wall of one supporting plate and the outer wall of the shell are each provided with at least one cooling mechanism. The cooling mechanism is used for cooling the two conductor discs. The liquid-cooling speed-regulating magnetic clutch is used for giving full play to the compensation and vibration isolation performance of magnetic transmission.

Owner:中国船舶重工集团公司第七0三研究所

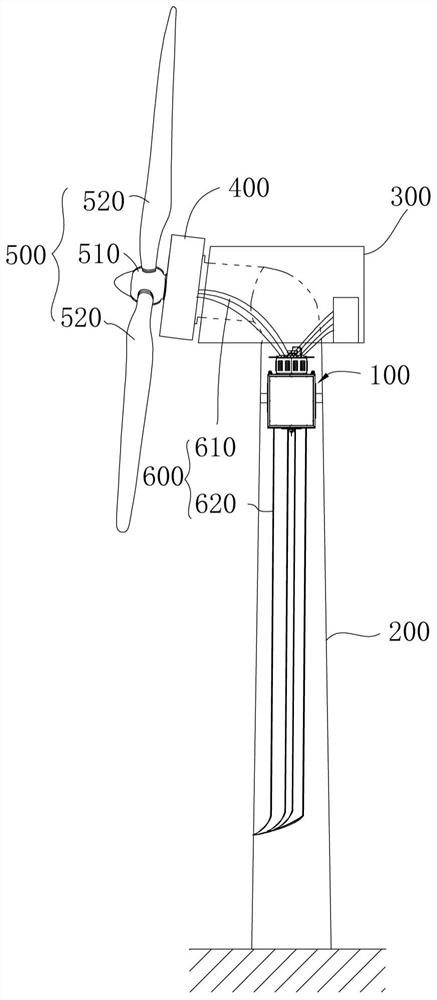

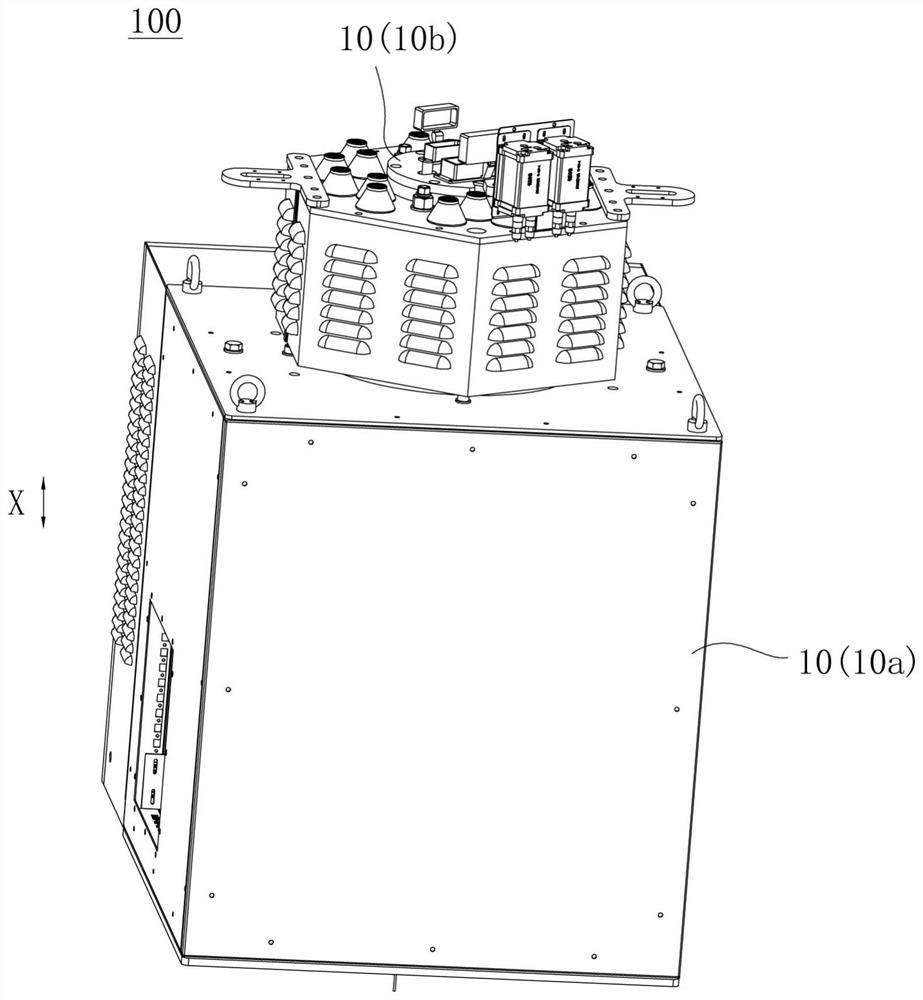

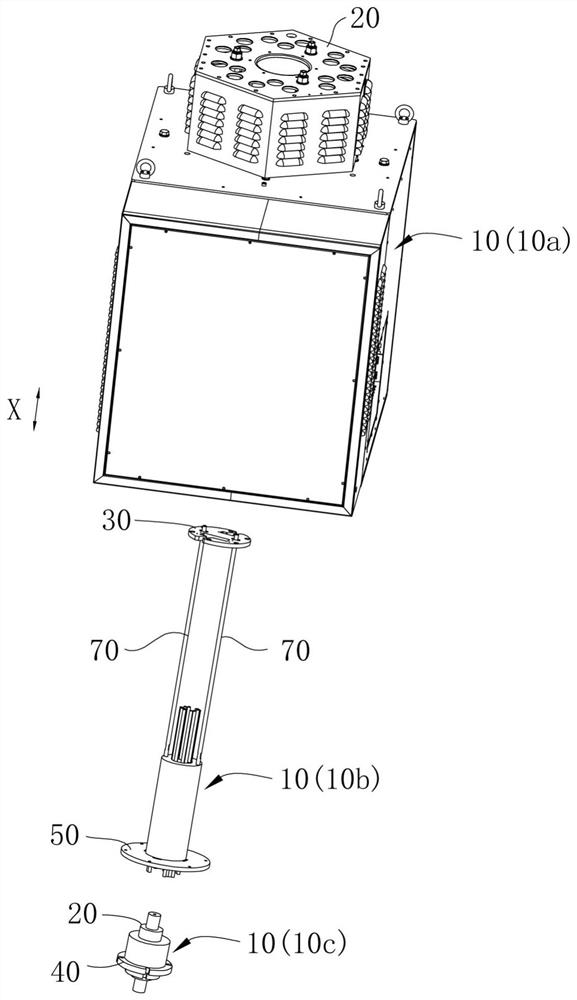

Combined energy transmission device and wind generating set

PendingCN113638843AAchieving detachable connection requirementsReduce usageWind motor supports/mountsWind motor combinationsElectrical connectionOptical energy

The invention relates to a combined energy transmission device and a wind generating set. The combined energy transmission device comprises a plurality of coaxially arranged energy transmission parts, and in every two adjacent energy transmission parts, at least part of one energy transmission part is located in the other energy transmission part; and each energy transmission part comprises a rotor and a stator which are in running fit and electrically connected with each other, the rotors of the energy transmission parts are independently arranged and are in insulated connection, and the stators of the energy transmission parts are independently arranged and are in insulated connection. According to the combined energy transmission device and the wind generating set of the embodiments, transmission of at least one of mechanical energy, electric energy, optical energy, hydraulic energy and the like can be met, limitation of installation space can be reduced or avoided, and construction is facilitated.

Owner:XINJIANG GOLDWIND SCI & TECH

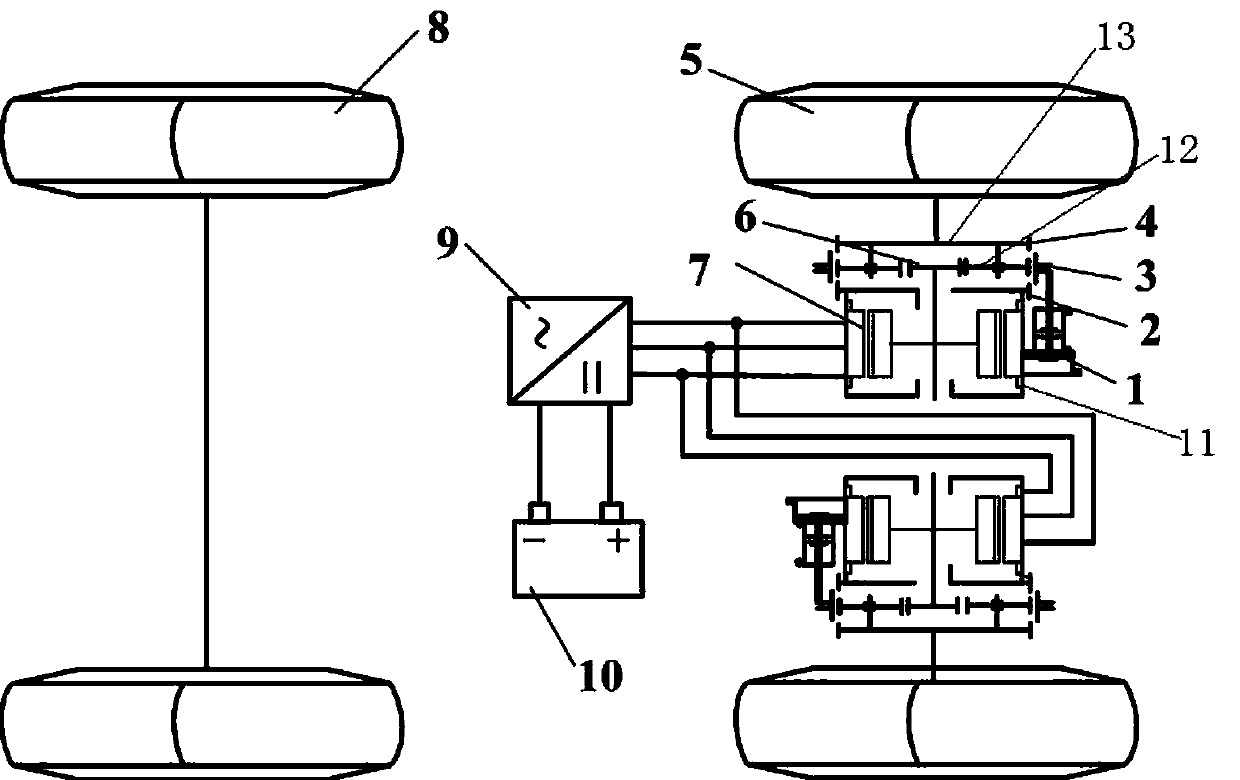

Automobile and electric axis driving system

InactiveCN110758095AMake full use of radial spaceSmall structureElectric propulsion mountingToothed gearingsElectric machineGear wheel

The embodiment of the invention provides an electric axis driving system and an automobile. The electric axis driving system comprises a box body, a differential, a motor, a first multi-linkage planetary gear set, a first clutch and a second clutch, wherein the differential comprises a differential shell; the motor comprises a motor output shaft; the first multi-linkage planetary gear set comprises a first sun gear, a first planet carrier, a first gear ring and a second gear ring, wherein the cross sections of the first gear ring and the second gear ring are mutually in parallel, the first sungear and the motor output shaft are in anti-torque connection, and the first planet carrier and the differential shell are in the anti-torque connection; the first clutch comprises a first steel sheet and a first friction sheet, wherein the first steel sheet and the first friction sheet have an on-off function, the first steel sheet is fixed on the box body, and the first friction sheet is fixedly connected with the first gear ring; and the second clutch comprises a second steel sheet and a second friction sheet, wherein the second steel sheet and the second friction sheet have an on-off function, the second steel sheet is fixed on the box body, and the second friction sheet is fixedly connected with the second gear ring. By use of the electric axis driving system provided by the embodiment of the invention, an axial occupation space is reduced, and the structural compactness of the whole system is improved.

Owner:SCHAEFFLER TECH AG & CO KG

Washing machine deceleration clutch and washing machine

ActiveCN105463771ALower the altitudeReduce volumeOther washing machinesTextiles and paperEngineeringHeight difference

The invention relates to a washing machine deceleration clutch comprising an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve. The deceleration device is at least formed by a central gear, a transmission gear, a transmission gear rack and an internal gear ring; the clutch device at least comprises a clutch shaft sleeve and a driving device driving a clutch shaft sleeve to axially move; the clutch shaft sleeve is mounted on the circumferential periphery of the deceleration device; the clutch shaft sleeve and the transmission gear rack can axially slide to each other, but cannot be circumferentially rotationally connected; the internal gear ring is connected with the output shaft sleeve; the driving device comprises at least one clutch platen coaxially arranged with the clutch shaft sleeve; the end surface of the clutch platen has height difference in an axial direction; the clutch platen circumferentially drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve. The washing machine deceleration clutch is simply structured and occupies little space in an axial direction; and overall height of the deceleration clutch can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

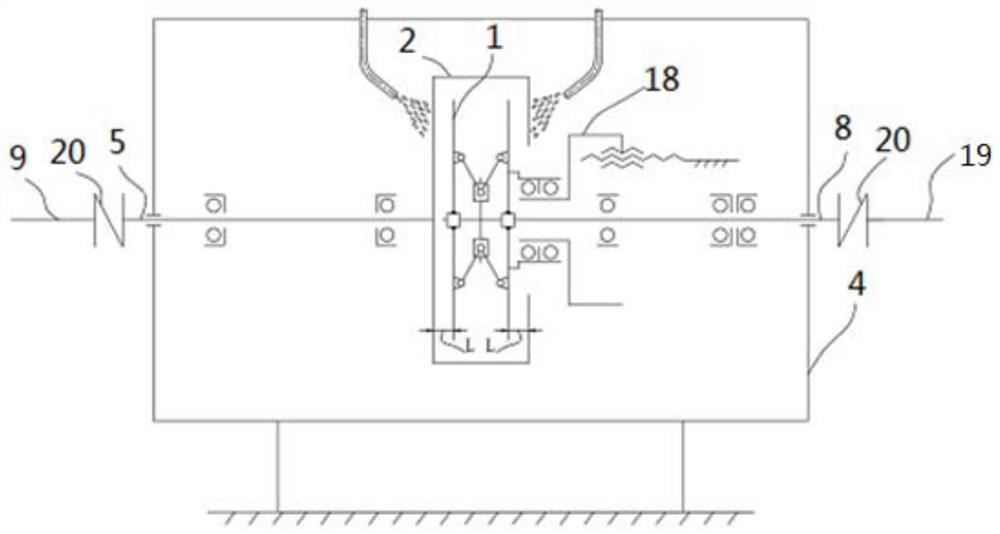

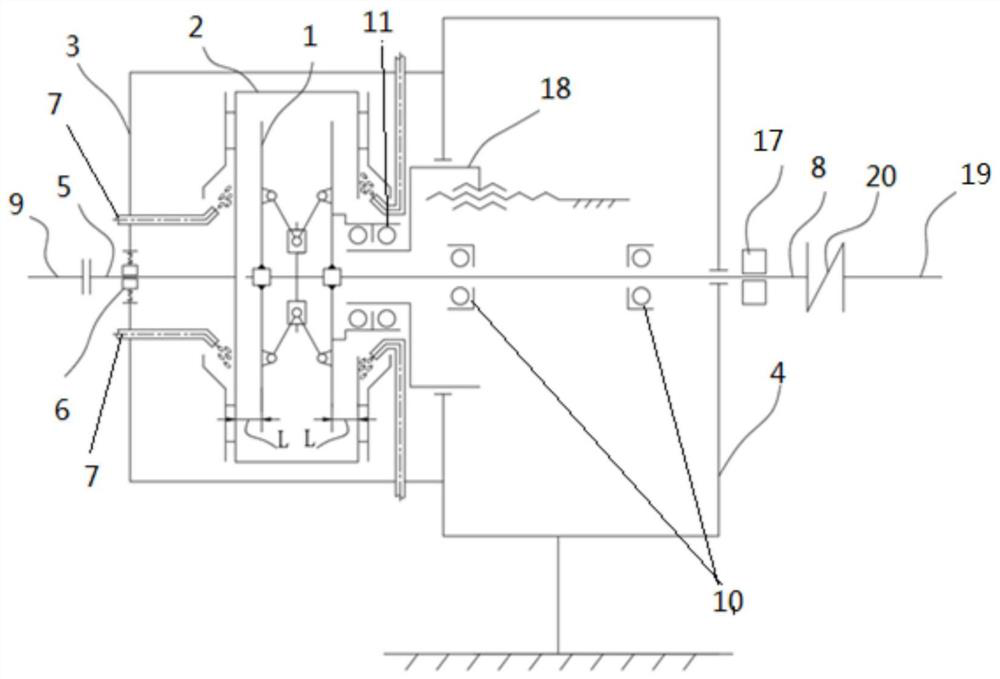

Decelerating clutch and washing machine

ActiveCN105297345ALower the altitudeReduce the overall heightOther washing machinesTextiles and paperEngineeringClutch

The invention relates to a decelerating clutch and a washing machine. The decelerating clutch comprises an input shaft, a decelerating device, a clutch device, an output shaft and an output shaft sleeve. The middle portion of a motor is hollow. At least a part of the decelerating device is arranged in the hollow portion such that the decelerating device and a projection of the motor on an axis of the decelerating clutch are partially overlapped. At least one part of the decelerating device is arranged in the hollow portion of the motor such that overall height of the decelerating clutch can be decreased. In the meantime, the clutch device is arranged on the periphery of the decelerating device such that the decelerating device and the projection of the motor on the axis of the decelerating clutch are partially overlapped. Therefore, space occupied by a conventional clutch device is saved and overall height of the decelerating clutch can be decreased. Accordingly, size of the washing machine is decreased with washing capacity unchanged. Or, washing capacity is increased with size of the washing machine unchanged.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

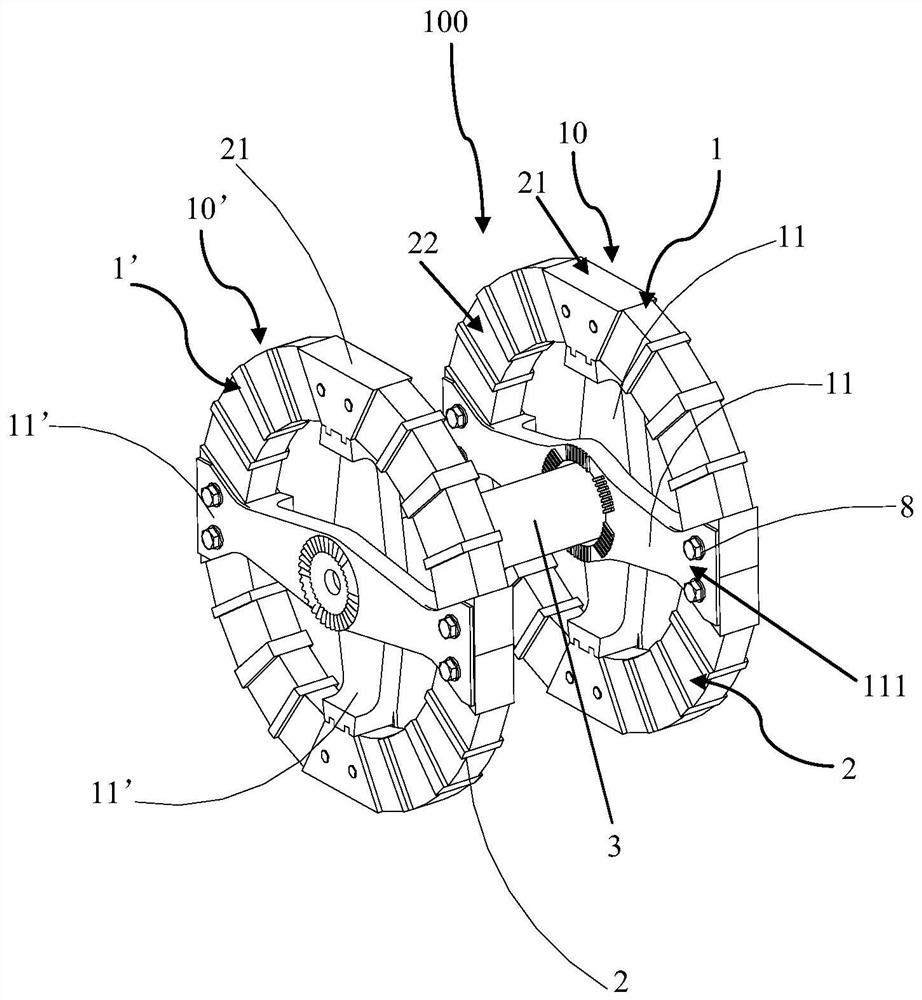

Connector

PendingCN109882513ACompact structureAxially takes up little spaceYielding couplingAxial displacementElastomer

The invention provides a connector. The connector comprises an elastomer unit with a part to be connected. The part to be connected is provided with connecting rod arms axially staggered by an angle;and connecting rod shafts are arranged on two sides of the connecting rod arms in the peripheral direction. The connecting rod shafts and the connecting rod arms are connected through elastic spherical hinges; and the axes of the elastic spherical hinges are arranged parallel to the axis of the part to be connected. The connector is compact in structure, less in axial occupied space and higher inradial and axial displacement compensation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

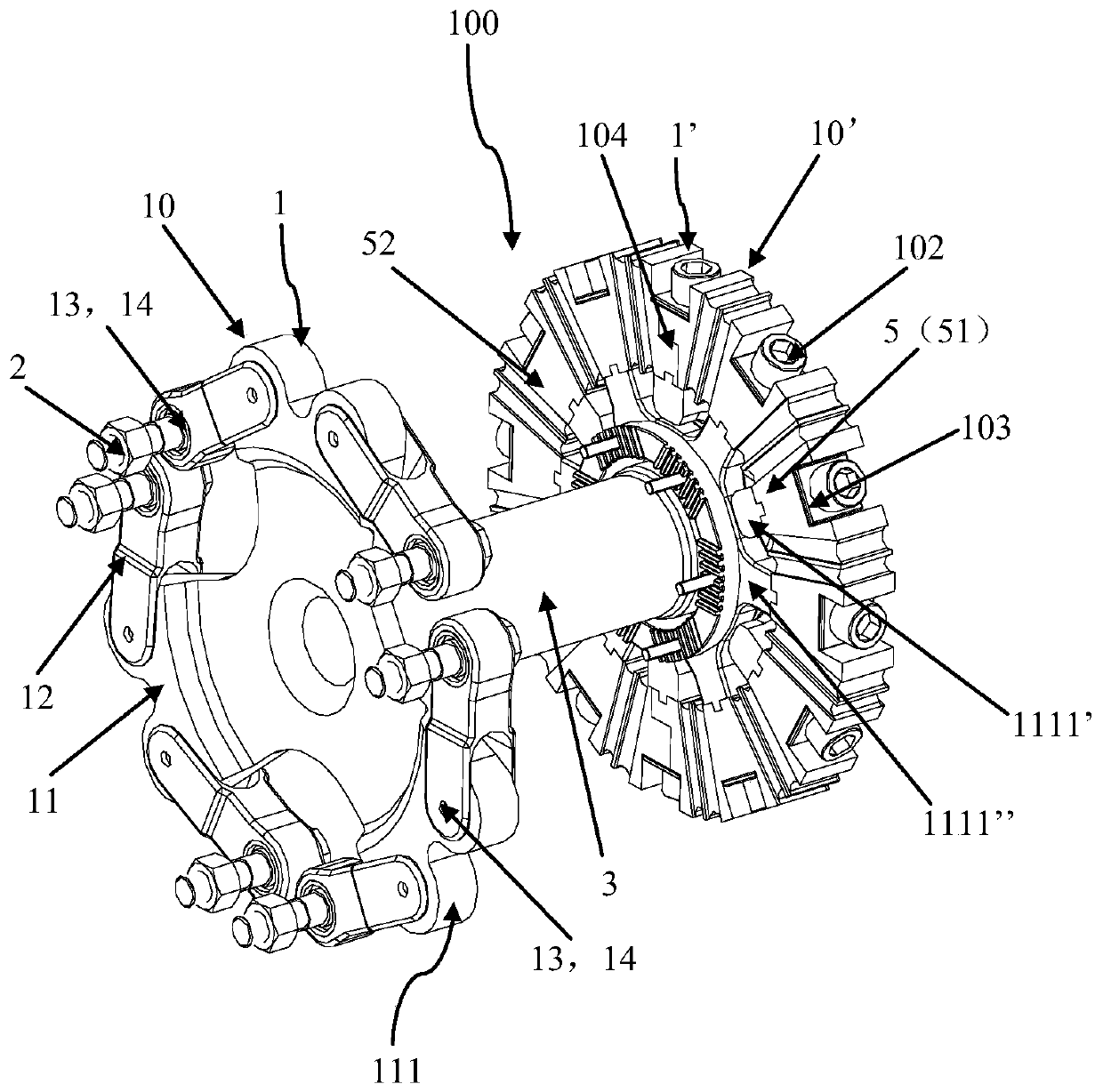

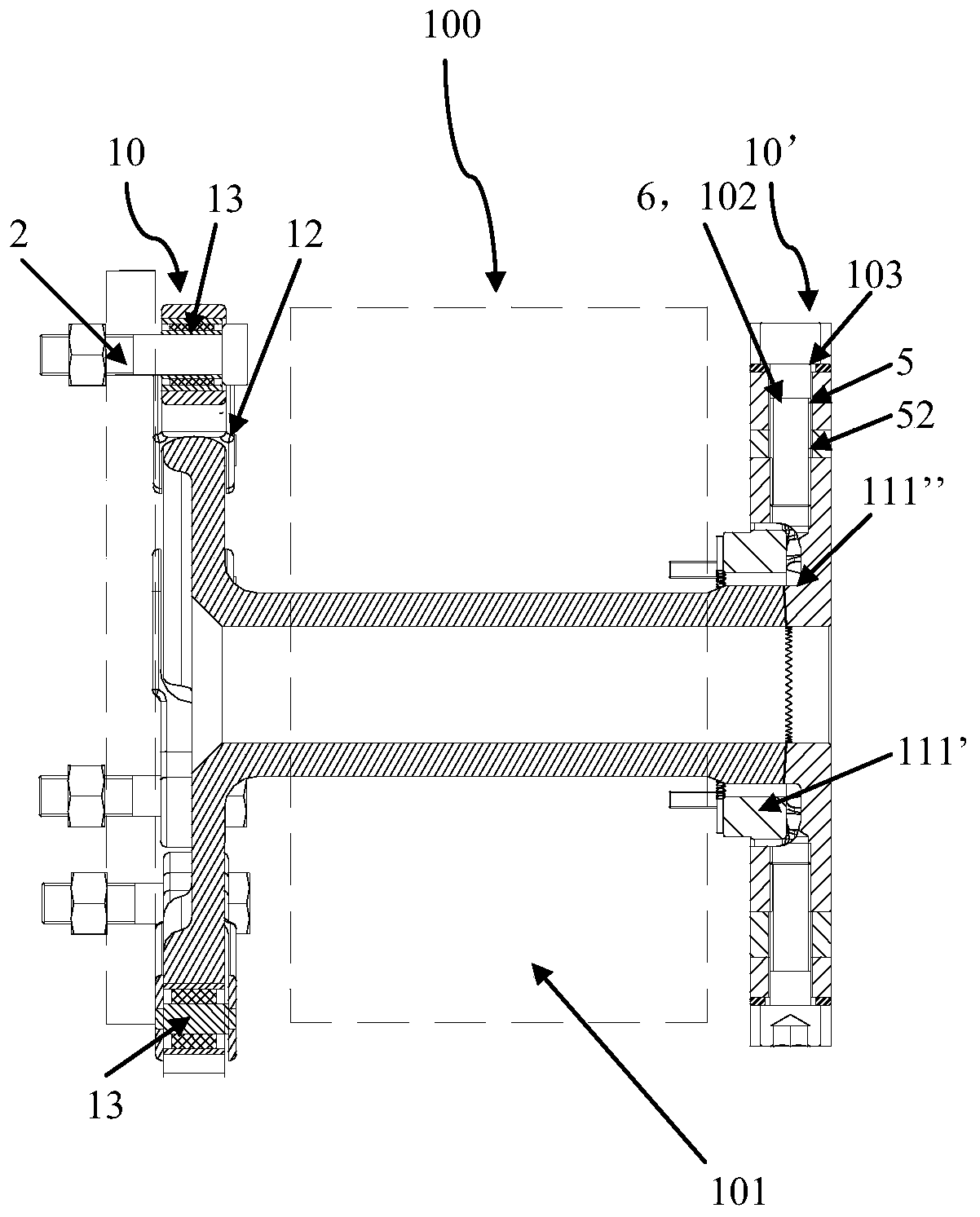

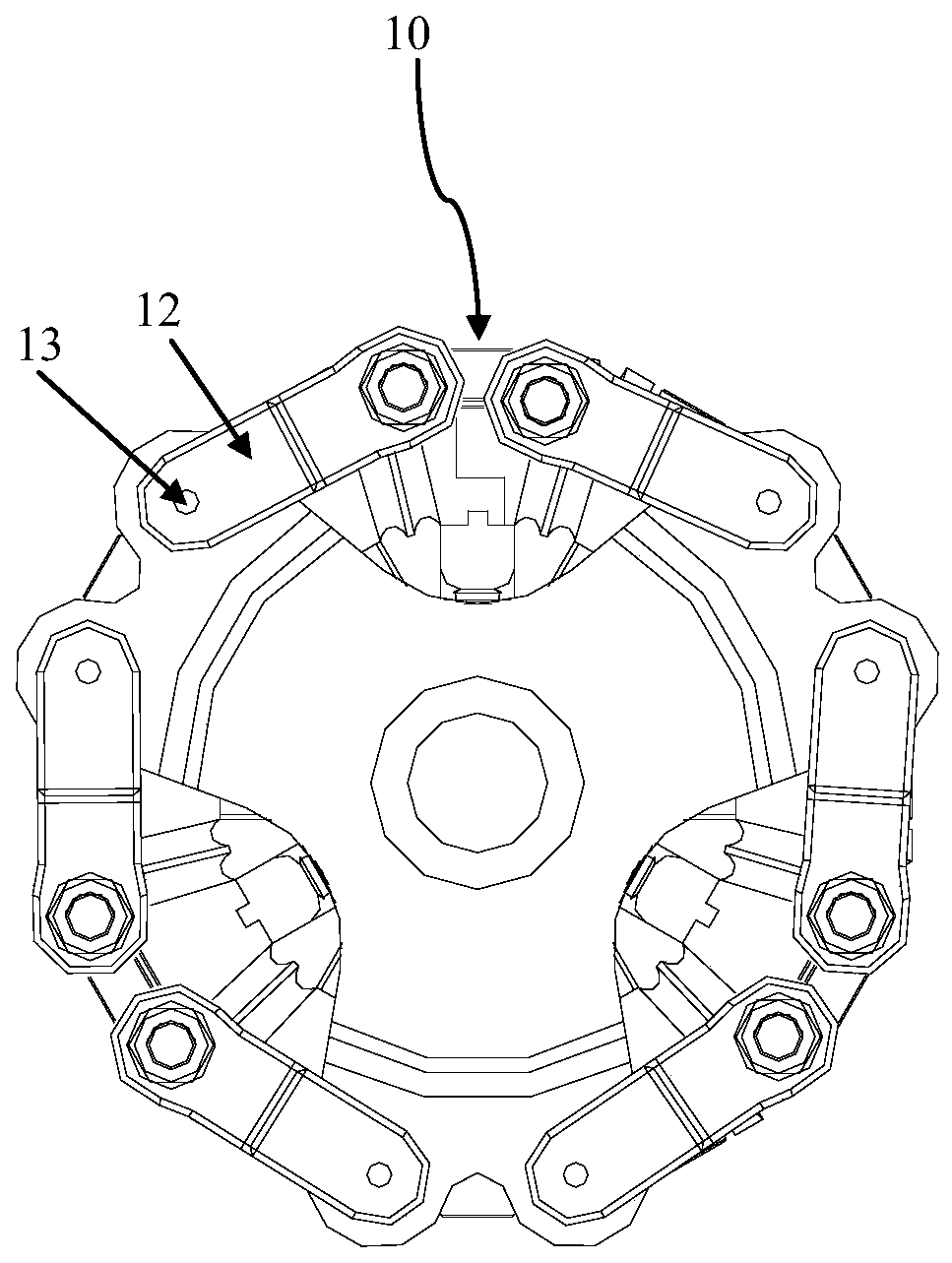

Permanent Magnet Synchronous Traction Motors for EMUs

ActiveCN104767337BImprove efficiencyIncrease powerSynchronous machine detailsMagnetic circuit rotating partsSynchronous motorPunching

The invention relates to a motor, in particular to a permanent-magnet synchronous traction motor for a motor train. The permanent-magnet synchronous traction motor for the motor train solves the problem that an existing permanent-magnet synchronous motor is not suitable for being directly used as a permanent-magnet synchronous traction motor for a motor train due to structure defects. The motor adopts a novel rotor magnetic circuit structure punching plate, a high-integration compact type rotor structure, a detachable connecting box structure and a lead structure. A connecting box can be conveniently disassembled so that the motor can be installed easily. A U-shaped magnetic circuit permanent magnet structure of an inner rotor is adopted, the magnetic separation bridge and circular bead design is added, and therefore the start and overload capacity of the motor can be improved. A rotor pressing ring at the driving end integrates rotor core pressing, permanent magnet end face pressing, rotor dynamic balancing and an inner seal ring labyrinth seal structure into a whole, the advantages that the structure is compact, the axial occupied space is small, and the installation is convenient are achieved, and the motor can be widely applied in the field of locomotive trains. According to the research, development and the operation of the permanent-magnet synchronous traction motor for the motor train, realistic bases are supplied for the permanent-magnet motor to research and develop a permanent-magnet traction motor structure with higher power, higher rotation speed and higher power density.

Owner:CRRC YONGJI ELECTRIC CO LTD

a connector

ActiveCN110001675BCompact structureAxially takes up little spaceLocomotive transmissionsVibration suppression adjustmentsEngineeringMechanical engineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

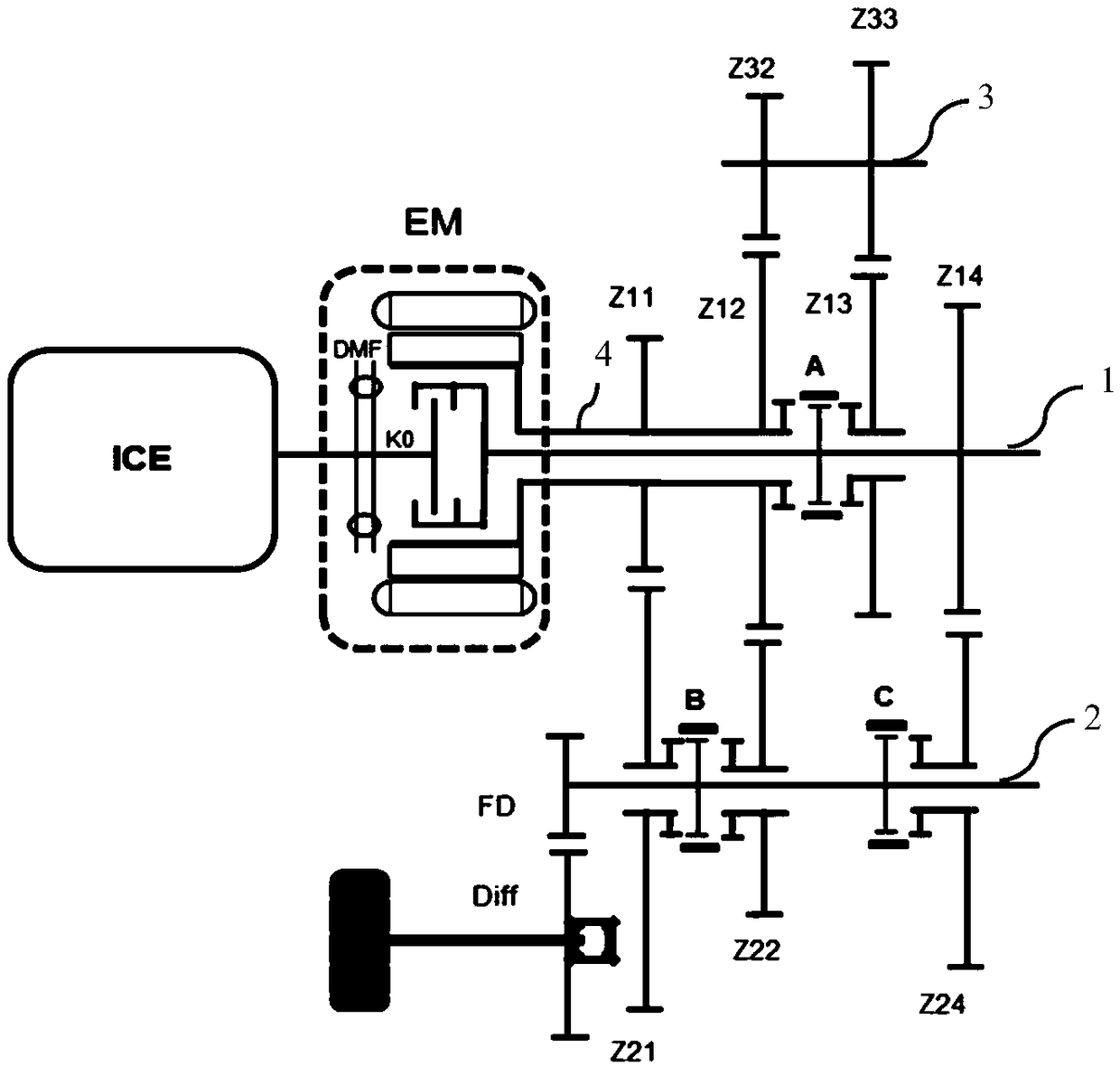

Hybrid power transmission

PendingCN111572330ALow costAvoid power outagesHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machinery

The invention discloses a hybrid power transmission which at least comprises an input shaft and an output shaft which are arranged in parallel. The input shaft and the output shaft are in transmissionconnection through a gear pair I and a gear pair II, and the output shaft is further provided with a differential mechanism in transmission connection with the output shaft. An auxiliary motor and amain driving motor are further included, the auxiliary motor is mechanically and directly connected with the engine, and electric power is transmitted to the differential mechanism through the gear pair II; and the main driving motor is directly connected with the differential mechanism and transmits the electric power to the differential mechanism, and the auxiliary motor and the main driving motor are high-speed, efficient and long-wheelbase motors with the same wheelbase. The hybrid power transmission has advantages that cost is reduced, a double-shaft design is adopted to reduce an axial occupied space of the gear pair, the auxiliary motor is mechanically and directly connected to the engine to provide inertia needed by the engine, and a damping disc is used in cooperation to reduce anaxial occupied space.

Owner:吉泰车辆技术(苏州)有限公司

a connector

ActiveCN109990009BCompact structureAxially takes up little spaceYielding couplingGearing detailsElastomerEngineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A washing machine deceleration clutch and washing machine

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and is in a connection with the annular gear in way of being capable of sliding relative to the annular gear but incapable of rotating relative to the same; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one clutch press plate coaxially arranged with the clutch shaft sleeve; and the clutch press plate can circumferentially rotate to drive the clutch shaft sleeve to axially move. The deceleration clutch is simply structured and axially occupies small space; and overall height of the deceleration height can be reduced and washing capacity can be increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

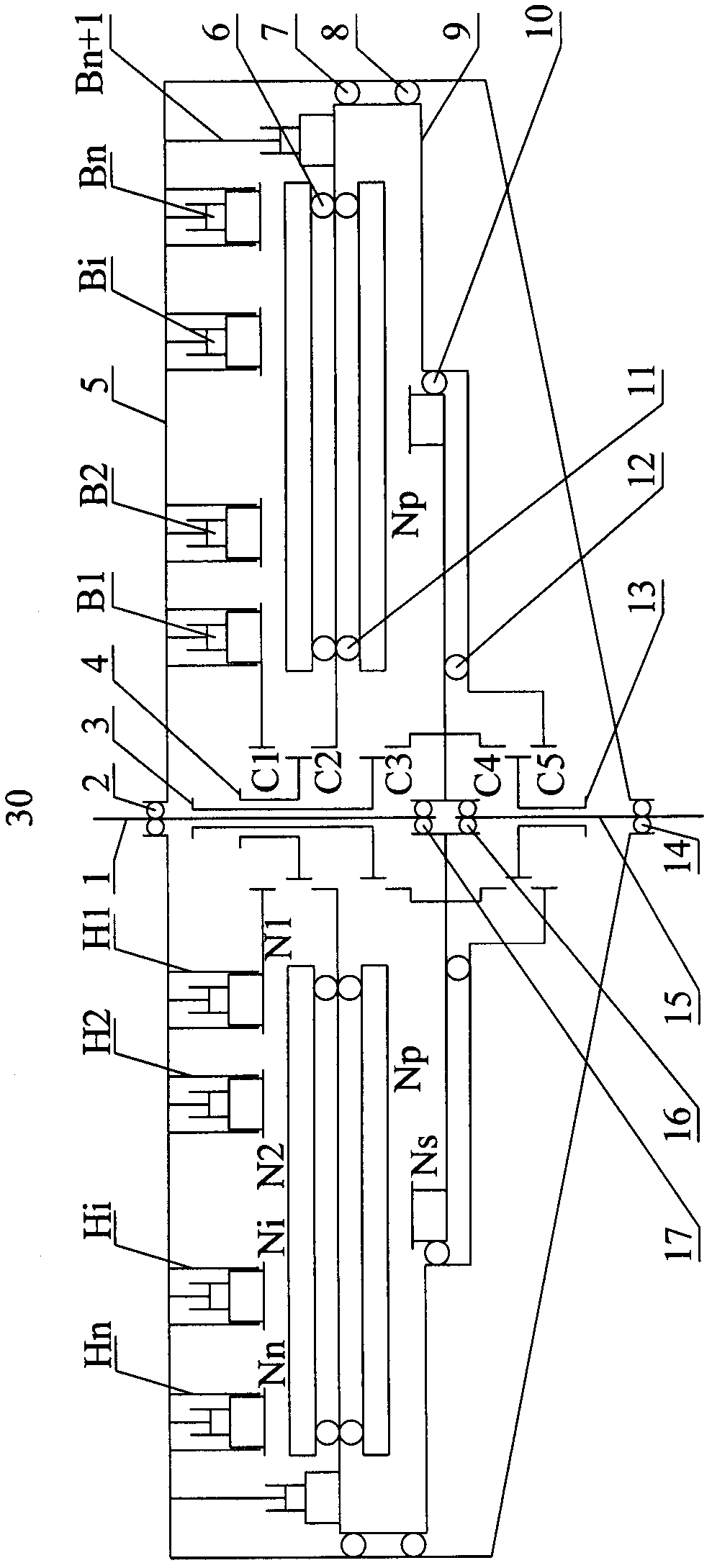

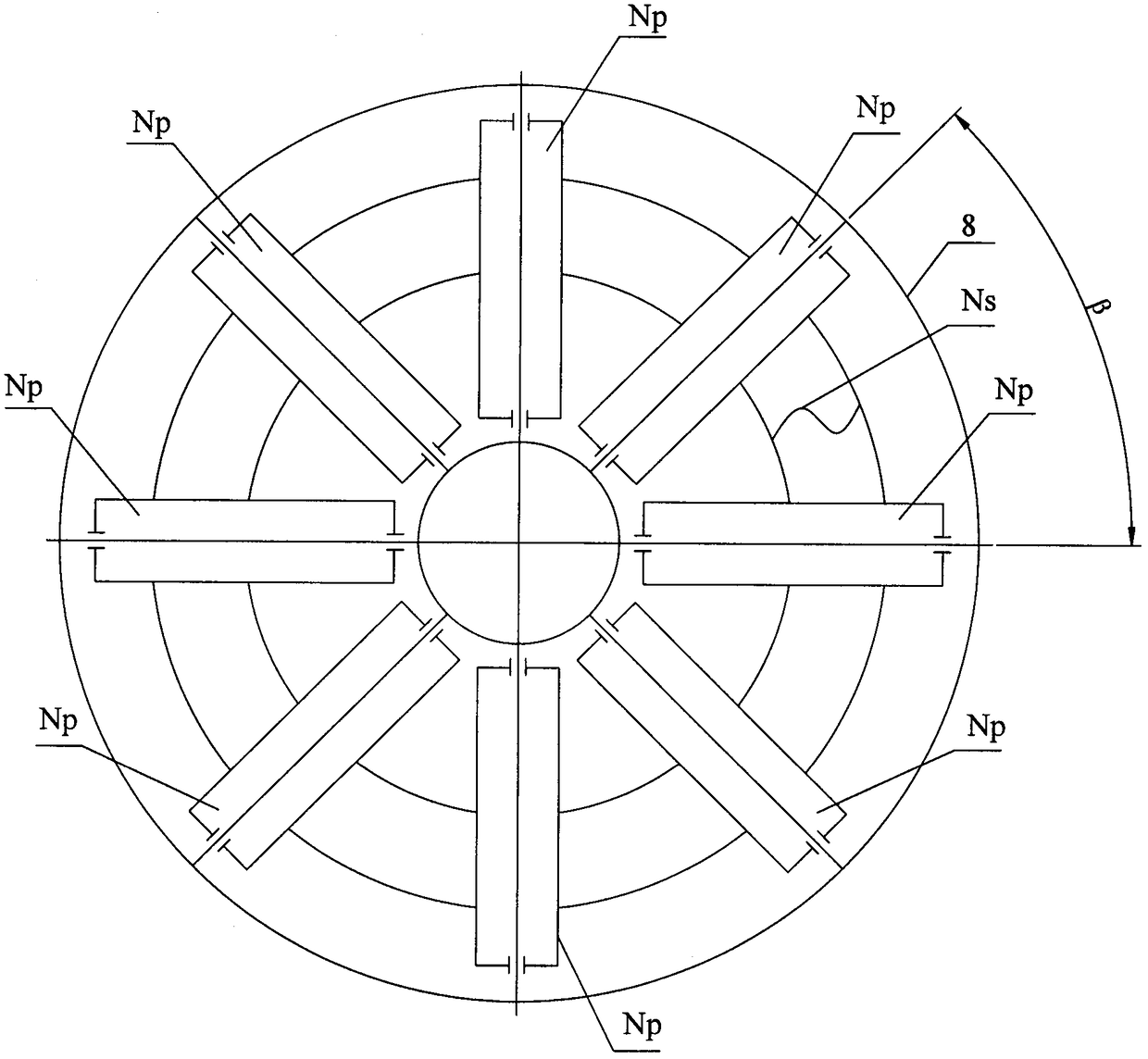

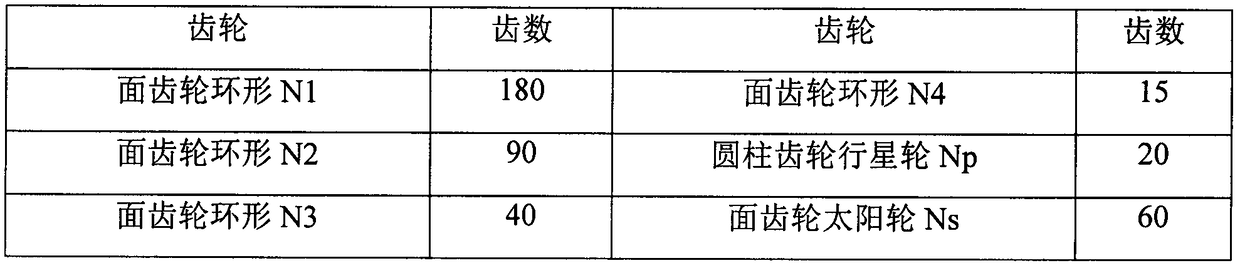

2n+2 gear transmission based on angle gear transmission mechanism

ActiveCN108240433AOptimize structure layoutEasy gear shiftingToothed gearingsTransmission elementsSupporting systemSpeed control system

The invention discloses a 2n+2 gear transmission based on an angle gear transmission mechanism (face gear or taper gear transmission mechanism). The 2n+2 gear transmission mainly comprises a box, an input and output shaft, a supporting system, a parallel multi-planet row speed control system based on the angle gear transmission mechanism, a clutch used for controlling gear switching and a brake. Different from a traditional planet transmission, a transmission multi-planet row wheel train can share a planet wheel, a planet carrier and a sun gear, two speed ratios can be increased when one gearelement capable of being switched between the fixed state and the idle state is introduced each time, when the number of the gear elements is n (n is larger than or equal to 1), 2n speed ratios can beobtained, one direct transmission speed ratio and one negative transmission speed ratio can be included, and 2n+2 gears can be obtained. Due to public design of main transmission components such as the sun gear, the planet wheel and the planet carrier, under the condition that the numbers of the gears are the same, the number of the utilized gears is smallest, and the beneficial effects of beingsimple in structure, reliable in operation, high in transmission efficiency and the like are achieved.

Owner:东营正诺技术服务有限公司

A washing machine deceleration clutch and washing machine

ActiveCN105332241BLower the altitudeReduce volumeOther washing machinesTextiles and paperDrive motorEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the clutch device at least comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is arranged outside an annular gear of the deceleration device and can slide relative to the annular gear in an axial way but cannot rotate relative to the same in the circumferential way; the driving device drives the clutch shaft sleeve to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the clutch shaft sleeve to axially move and the other end is provided with a driving end in a transmission connection with a driving motor. The deceleration clutch is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and overall height of the deceleration height can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Axial limiter suitable for transmission case of numerical control floor type boring and milling machine

InactiveCN101850430ASimple structureEasy to assembleBoring/drilling machinesNumerical controlAxial force

The invention discloses an axial limiter suitable for a transmission case of a numerical control floor type boring and milling machine. The axial limiter comprises two semicircular limit blocks sleeved on the outer circle of a nut in the transmission case. A protruded step is arranged on the semicircular limit blocks and is matched with a limit groove reserved on the outer circle of the nut; and a locking sleeve is sleeved out of the semicircular limit blocks and is provided with an ejecting screw hole. The axial limiter can bear a larger axial force and ensure axial pressing so as to ensure axial precision.

Owner:德阳嘉龙机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com