Automatic transmission for bicycle and transmission system

A technology for automatic transmissions and bicycles, applied to vehicle gearboxes, chain/belt transmissions, vehicle components, etc., can solve the problems of fast wear of chains and toothed discs, high manufacturing costs, high maintenance costs, etc., to reduce weight and service life Long, reduce power loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

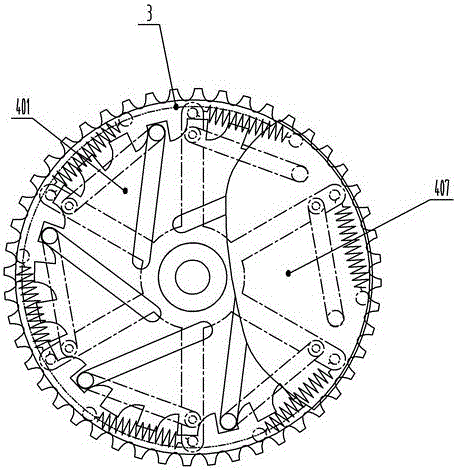

[0041] see Figure 1-8 , in the figure, the bicycle automatic transmission of the present invention includes a floating chainring 3 and a floating chainring driver 4, and the floating chainring 3 is installed on the floating chainring driver 4.

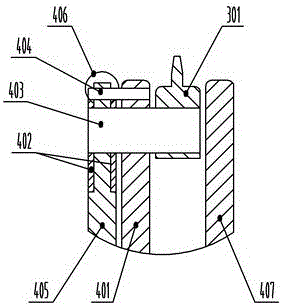

[0042] Wherein the floating toothed disk driver 4 includes a driving disk 401 , a moment arm 402 , a gear tooth 403 , a pin shaft 404 , an adjusting disk 405 , a torsion spring 406 , and a guide disk 407 .

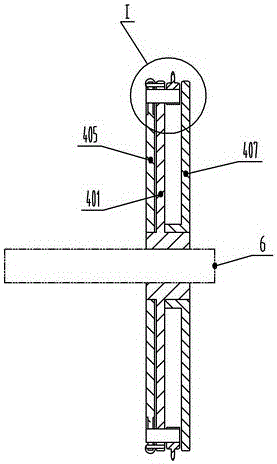

[0043] Wherein the guide disc 407 and the adjustment disc 405 are located on both sides of the drive disc 401 respectively, and are connected with the drive disc 401 through threaded installation. The driving disc 401 is a disc-shaped structural component with a boss 4011. The boss 4011 has a middle hole 4012 passing through both sides of the driving disc 401, and the driving disc 401 is installed on the bicycle center shaft 6 through the middle hole 4012. The guide plate 407 is a disc-shaped structural part with a threaded hole ...

Embodiment 2

[0050] see Figure 9 In the figure, the bicycle transmission system of the present invention includes a floating chainring 3, a floating chainring driver 4, and a flywheel 1, a chain 2, a rear axle 5, a center shaft 6, a crank 7, a pedal 8 and a hub 9.

[0051] The flywheel 1 is a single-piece flywheel, and the flywheel 1 is installed on the hub 9 through the middle hole of the flywheel with a keyway and the freewheel, the hub 9 is installed on the frame through the rear axle 5, and the flywheel 1 is connected to the floating chainring through the chain 2 3 Cooperate connection, the floating chainring 3 is installed on the floating chainring driver 4, the floating chainring driver 4 is installed on the central shaft 6 through the middle hole, the pedal 8 is installed on the crank 7, and the crank 7 is installed on both ends of the central shaft 6 end, the central axis 6 is installed on the bottom bracket of the vehicle frame.

[0052] The structures of the floating toothed di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com