Axial limiter suitable for transmission case of numerical control floor type boring and milling machine

A transmission box and floor boring technology, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problem of easy deformation, unsuitable CNC floor boring and milling machine transmission box, affecting axial accuracy, etc. problem, to achieve the effect of small space, simple structure and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

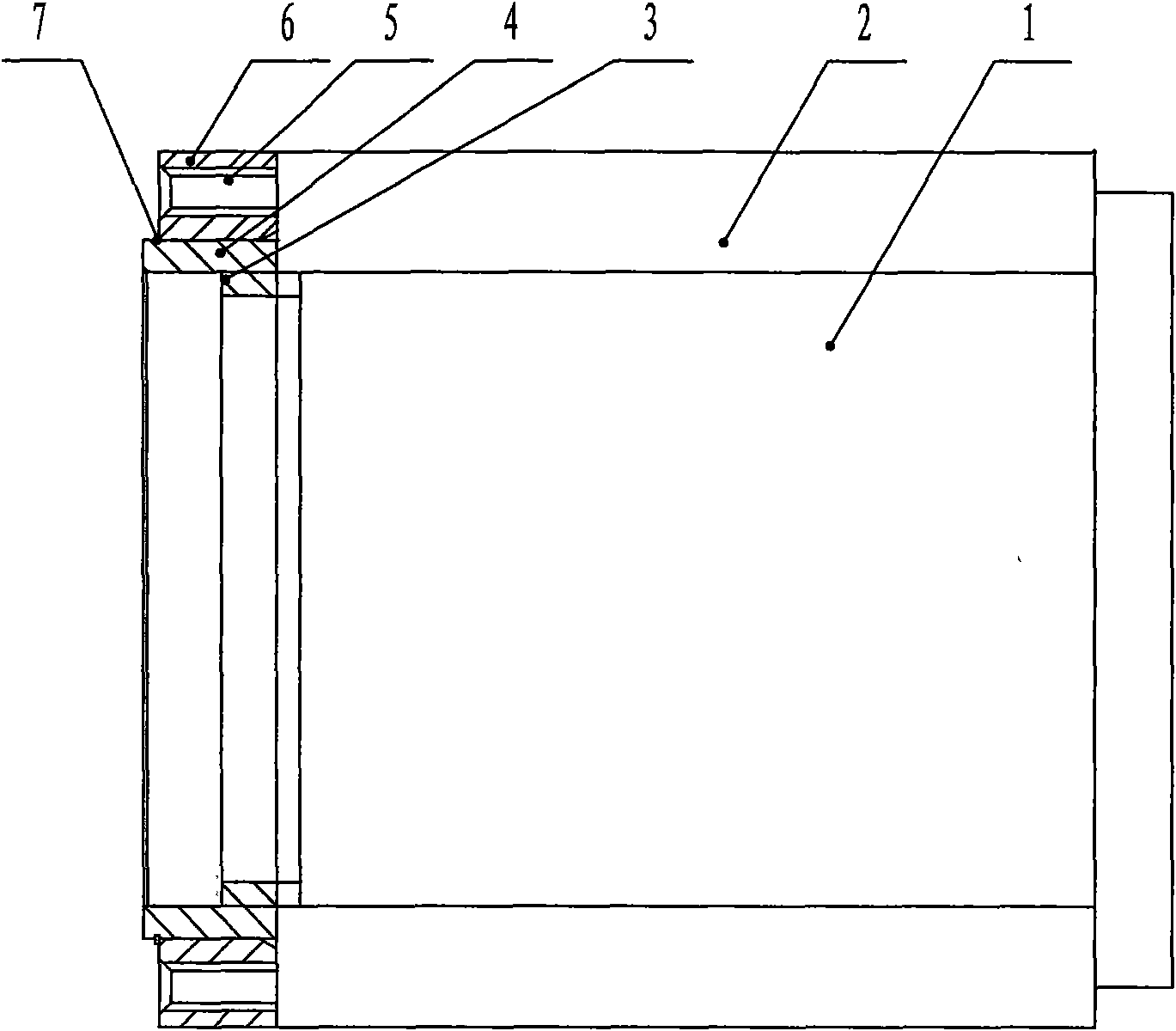

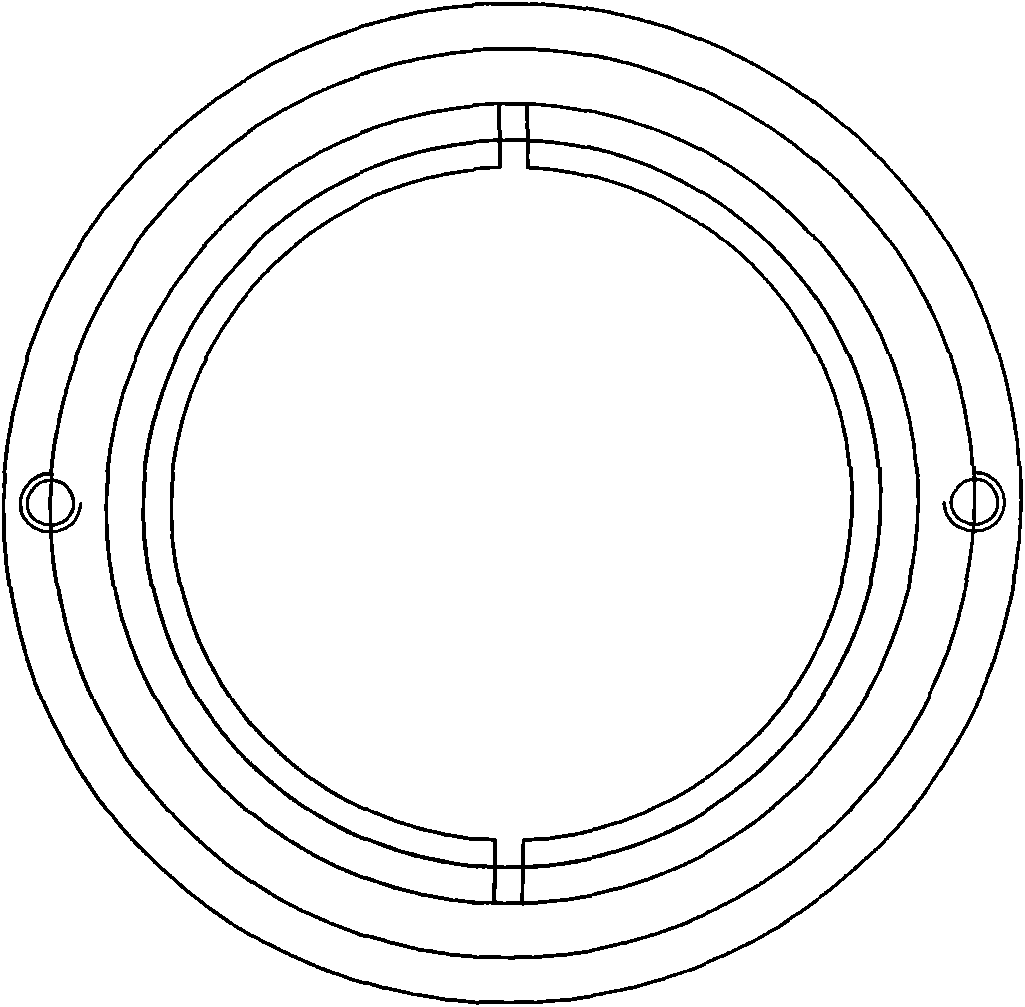

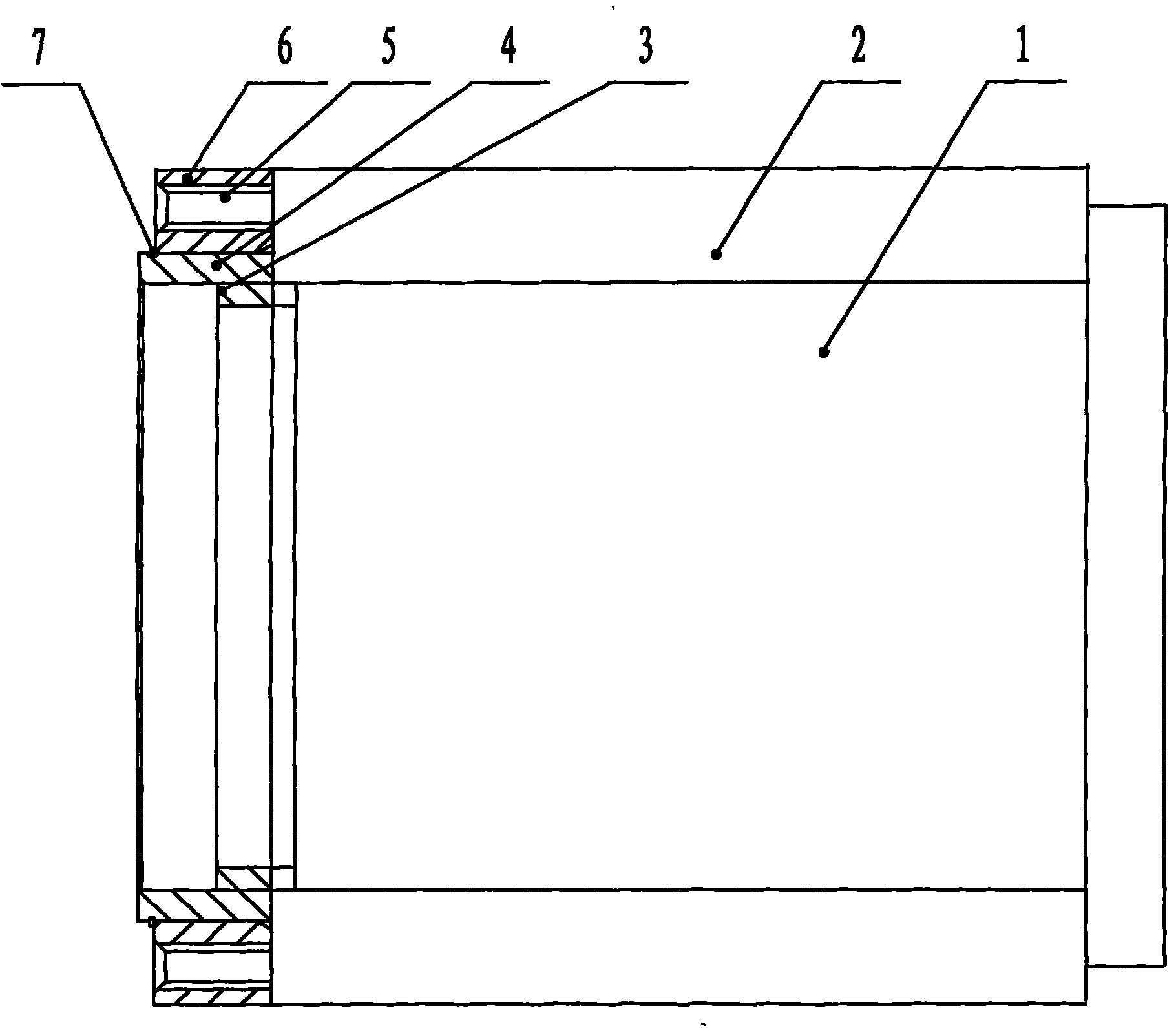

[0020] The invention discloses an axial limiter suitable for a transmission box of a CNC floor boring and milling machine, comprising two semicircular limit blocks 4 sleeved on the outer circle of a nut 1 in the transmission box. The block 4 is provided with a protruding step 3, and the step 3 cooperates with the limit groove provided on the outer circle of the nut 1. The semicircular limit block 4 is covered with a locking sleeve 6, and the locking sleeve 6 is Ejection screw holes 5 are provided.

Embodiment 2

[0022] A preferred embodiment of the present invention: with reference to the description attached figure 1 and 2 , the present invention is composed of two semicircular limit blocks 4 that have a cooperative relationship with the outer circle of the nut 1 . The semicircular limit block 4 has a step 3, the width of the step 3 is determined according to the size of the limit groove of the nut 1 and the size of the axial force, and cooperates with it to ensure accurate axial limit; the semicircle A locking sleeve 6 with two ejected screw holes 5 is placed on the outer surface of the shape limiting block 4, and the locking sleeve 6 locks the semicircular limiting block 4 during work, and the locking sleeve is fixed with the retaining ring 7 6 position to ensure reliable operation of the shaft end limiter. During maintenance, two screws are screwed into two ejection screw holes 5 to withstand the end face of the nut sleeve 2 and the lock sleeve 6 can be ejected from the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com