Thrust vector controlled electromechanical servo system

An electromechanical servo system and thrust vector control technology, applied in the field of aircraft, can solve problems such as tight space layout, large occupied space, and limited installation size, so as to meet space requirements, reduce occupied space, and reduce axial occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

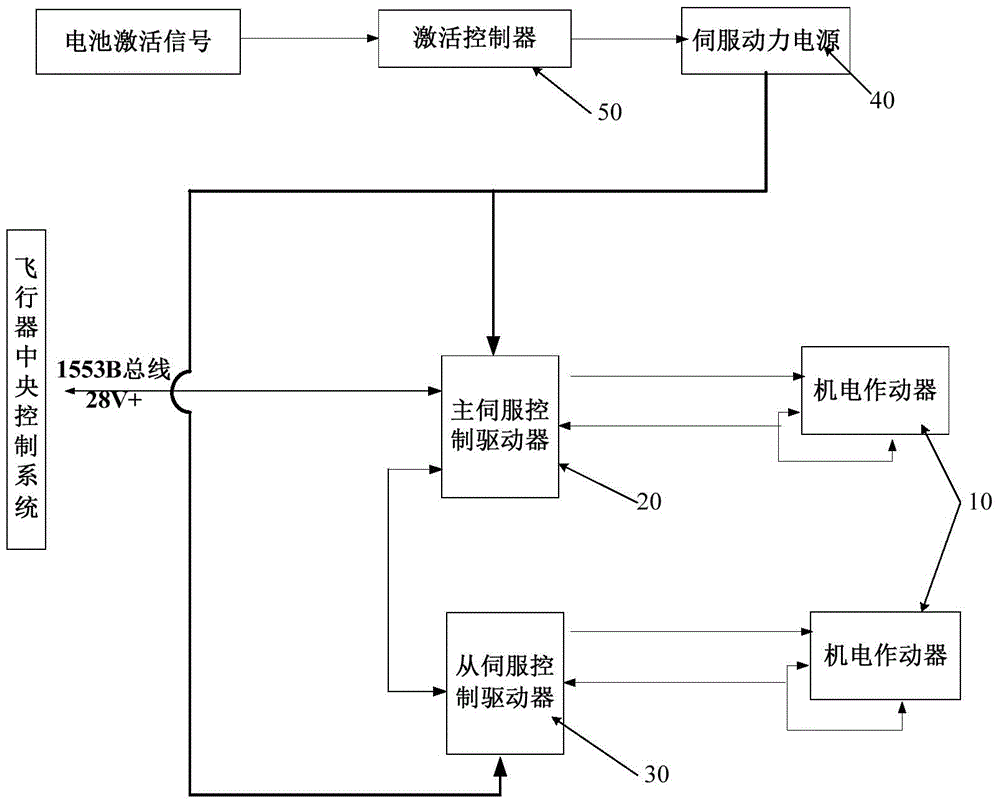

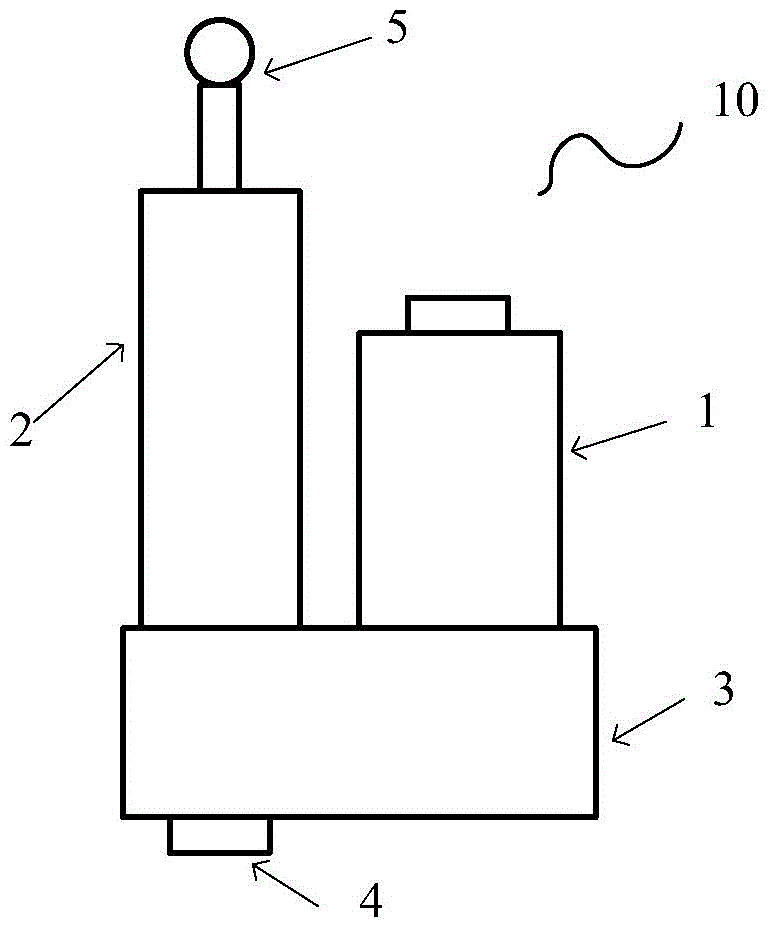

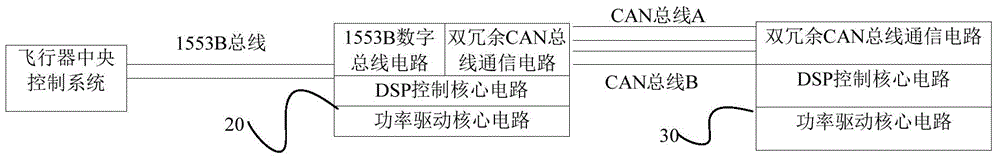

[0025] like Figures 1 to 2 As shown, the electromechanical servo system of the thrust vector control of the present invention is described with the thrust vector control of the launch vehicle. In the present invention, the electromechanical servo system includes two electromechanical actuators 10, one main servo control driver 20, one The slave servo control driver 30 and a servo power supply 40 for providing power, wherein the master servo control driver 20 and the slave servo control driver 30 drive and control one electromechanical actuator 10 respectively, and the electromechanical actuator 10 is a parallel type electromechanical actuator. The parallel electromechanical actuator includes a servo motor 1 and a ball screw transmission mechanism 2 and a gear transmission mechanism 3 that drives and connects the servo motor 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com