Permanent magnet offset radial magnetic bearing

A technology of permanent magnet bias and magnetic bearing, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of complex structure of the same polarity, low suspension power consumption, and many control coils, etc., and shorten the axial direction. The effect of occupying space, reducing size and weight, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

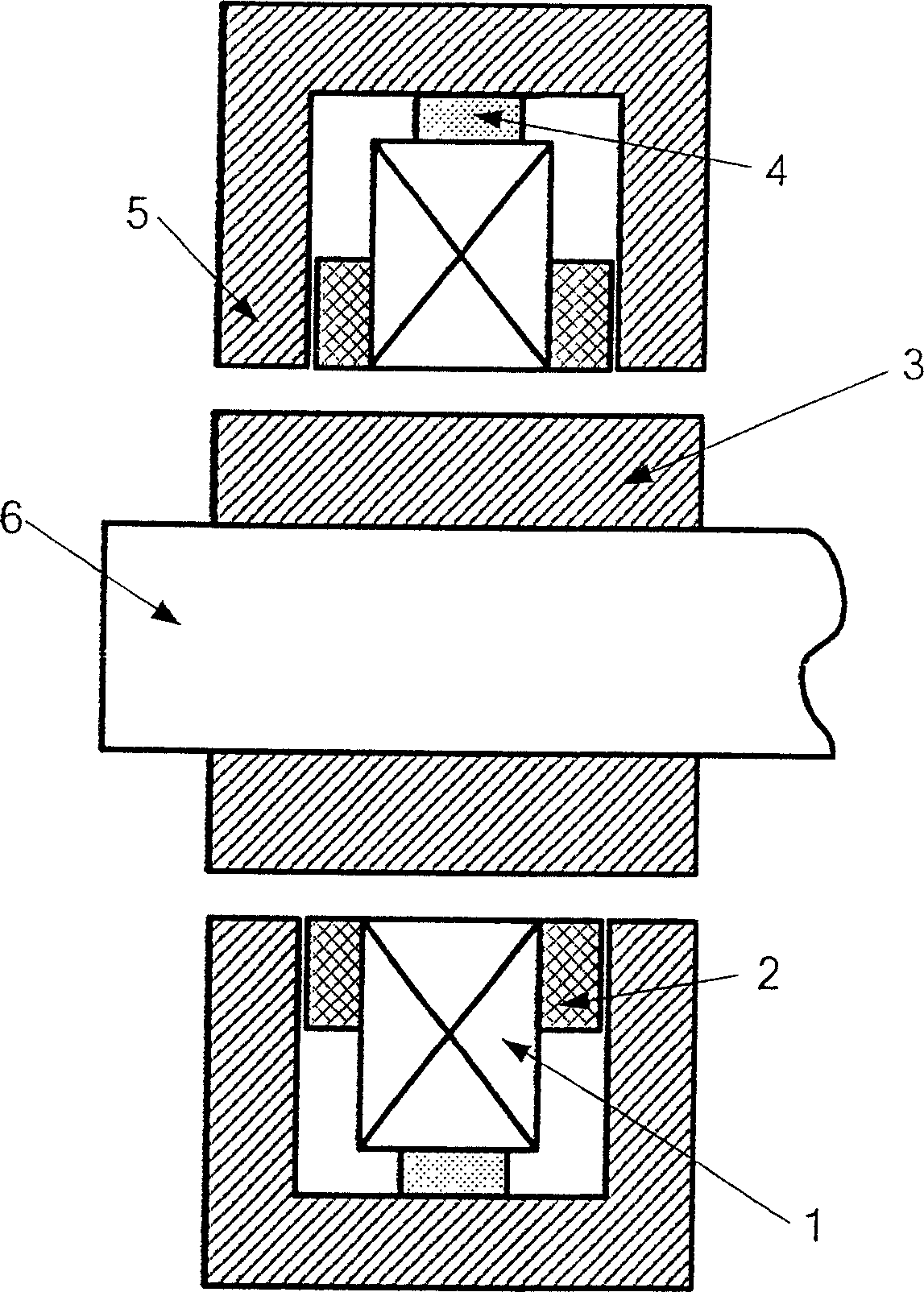

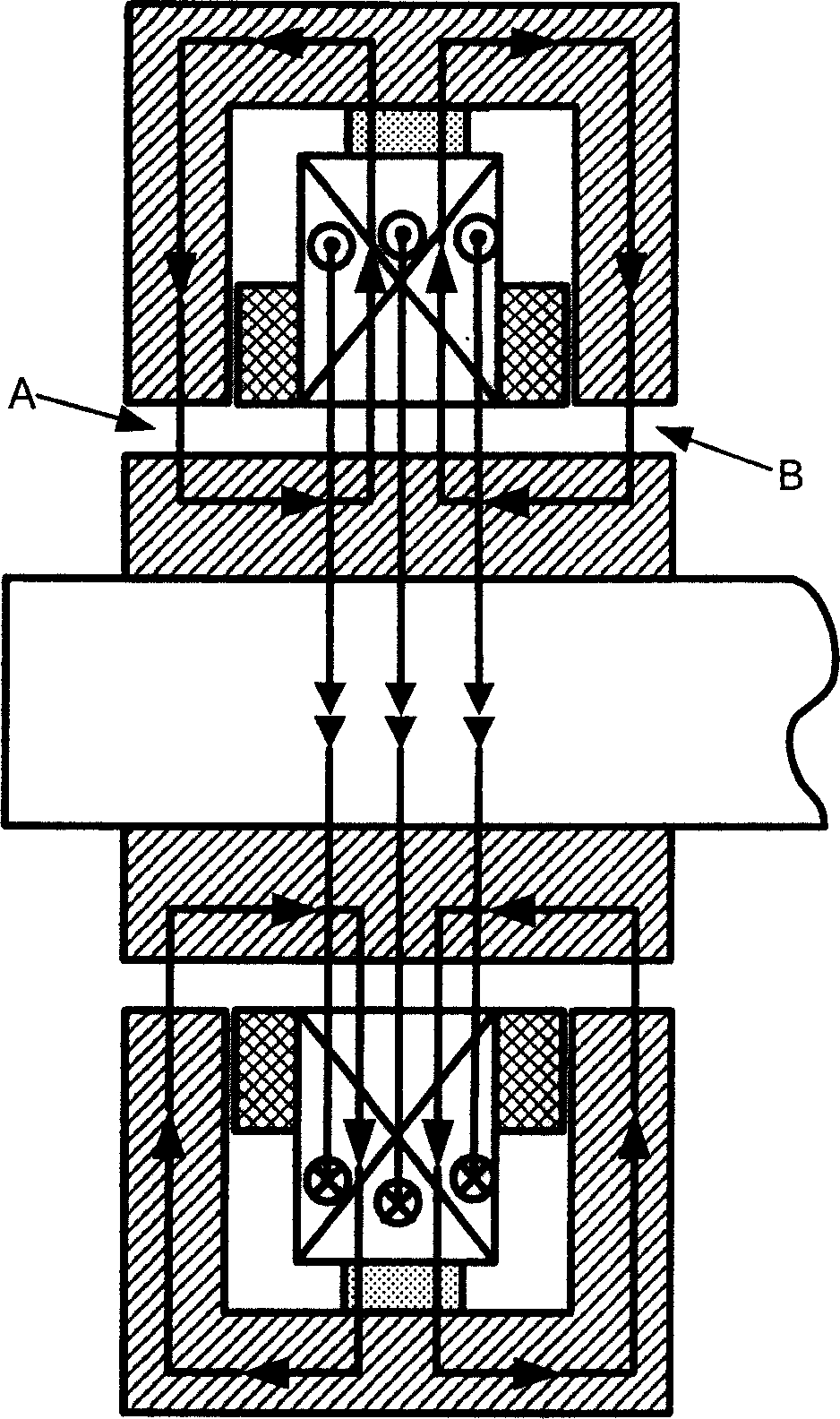

[0011] figure 1 It is a schematic diagram of the permanent magnet bias radial magnetic bearing structure of the present invention. The radial stator 1 in the figure is made of laminated silicon steel sheets and has a two-pole structure. Control windings 2 are wound on four teeth, and the two opposite The windings on each tooth are connected in series, the annular permanent magnet 4 is mounted on the middle position outside the radial stator 1, the outer magnetic pole core 5 and the rotor iron core 3 are made of electric pure iron, and the outer magnetic pole core 5 is set in the radial direction On the outer circle of the stator 1 , its inner end surface is in contact with the annular permanent magnet 4 , and the rotor core 3 sleeved on the rotor 6 is placed in the stator 1 . The bias magnetic flux generated by the annular permanent magnet passes through the outer magnetic pole core, air gap A (or air gap B), rotor core, radial air gap and radial stator in turn to form a loop,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com