Integrated external spring compensation type mechanical sealing device

A mechanical seal device and spring compensation technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of inability to install mechanical seal devices, failure of mechanical seal devices, and reduced service life, so as to achieve long service life and shaft The effect of small installation size and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

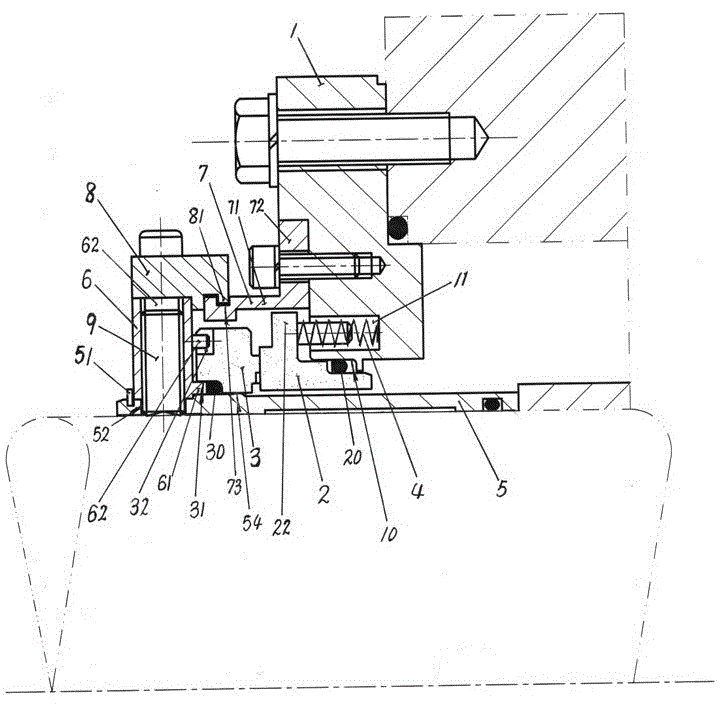

[0018] The integrated external spring compensation type mechanical seal device of the present invention consists of a gland 1, a static ring 2, a moving ring 3, a compensation spring 4, a shaft sleeve 5, a transmission ring 6, an auxiliary sealing ring 20 for the static ring, a moving ring sealing ring 30, and a limiter. The bit ring 7 and the positioning block 8 are formed;

[0019] On the shaft hole on the left side of the gland 1 (i.e. outside the gland), there is a spigot platform 10, the right end of the static ring 2 is slidably fitted with the spigot platform 10, and the spigot platform 10 and the right end of the static ring 2 Static ring auxiliary sealing ring 20 is arranged between the parts;

[0020] A protruding ring 22 is provided at the left end of the static ring 2, and a positioning pin is fixed on the left end surface of the gland 1 to cooperate with the pin hole provided on the protruding ring 22 of the static ring to carry out anti-rotation positioning of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com