Multiple rigidity-variable automotive suspension spring

A technology of automobile suspension and variable stiffness, which is applied in the direction of springs/shock absorbers, coil springs, mechanical equipment, etc., can solve the problems of spring coil collision, noise, ride comfort, poor comfort, etc., to reduce inclination, reduce Noise, the effect of lowering the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

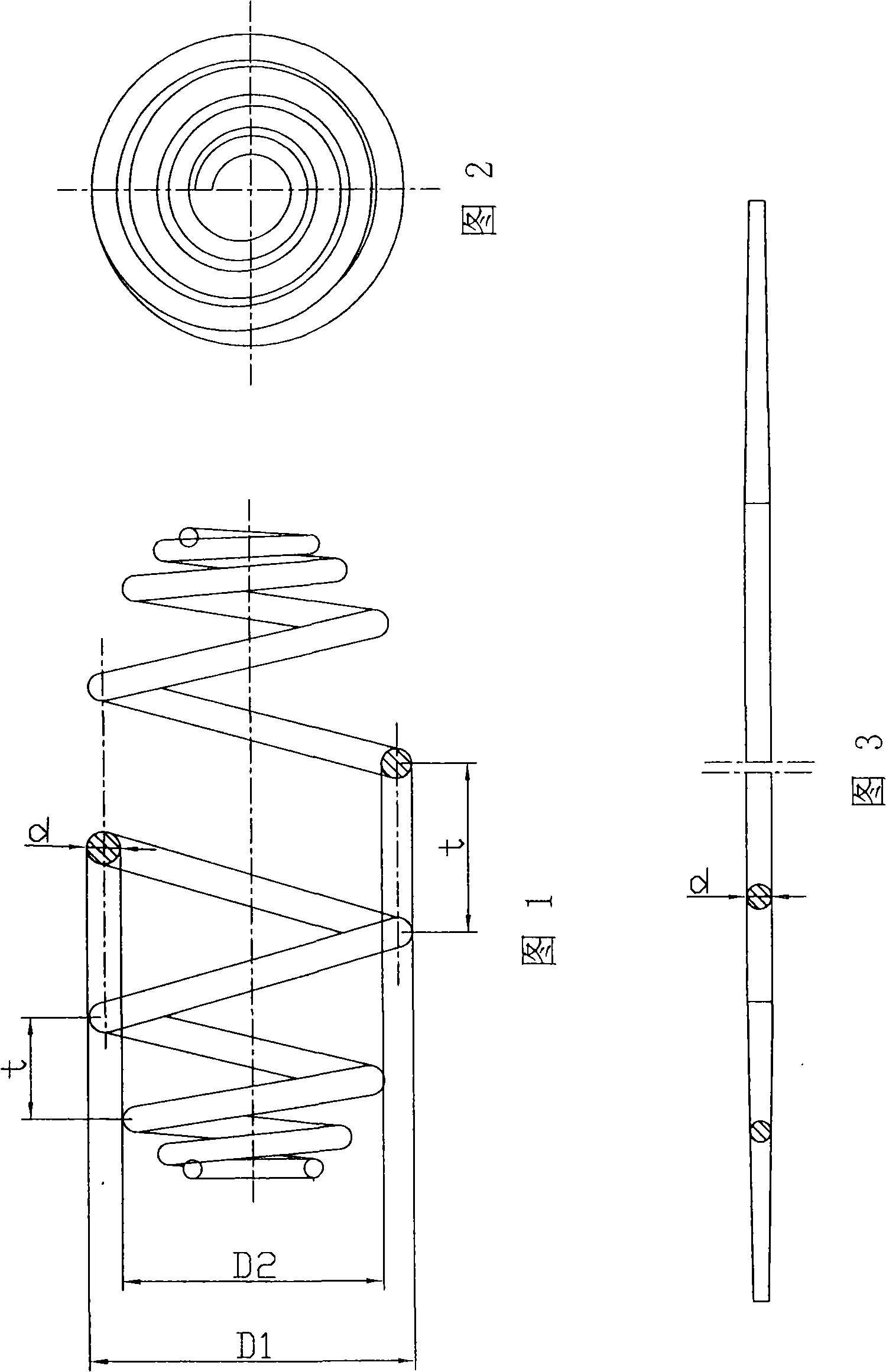

[0021] As shown in Figures 1, 2, and 3, multiple variable stiffness automobile suspension springs are wound into a spiral shape by a spring wire whose diameter gradually becomes thinner from the middle to both ends, and the pitch of the helical spring is from the middle to both ends. From large to small, the outer diameter of the spring ring and the inner diameter of the spring ring change from large to small from the middle part to the two ends.

[0022] The following is a set of specific technical parameters:

[0023] Design stress: 1100-1200MPa.

[0024] Dimensional parameters (mm): the diameter of the spring wire d is 8-20; the inner diameter of the spring coil at both ends is D2≥30; the outer diameter of the spring coil at the middle part is D1≤200; the expansion length of the material diameter change at both ends can reach 1200; Pressure and limit height ≤ 45.

[0025] Load characteristics: 1. Stiffness changes with load; 2. Stiffness deviation ≤ ± 4%.

[0026] Fatigu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com