Gas oil separation structure of internal combustion engine crankcase ventilation system

A technology for crankcase and ventilation system of internal combustion engine, applied in the field of lubrication system, can solve the problems of high oil consumption and low consumption of lubricating oil, and achieve the effect of high oil-gas separation efficiency, reduced consumption of lubricating oil and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

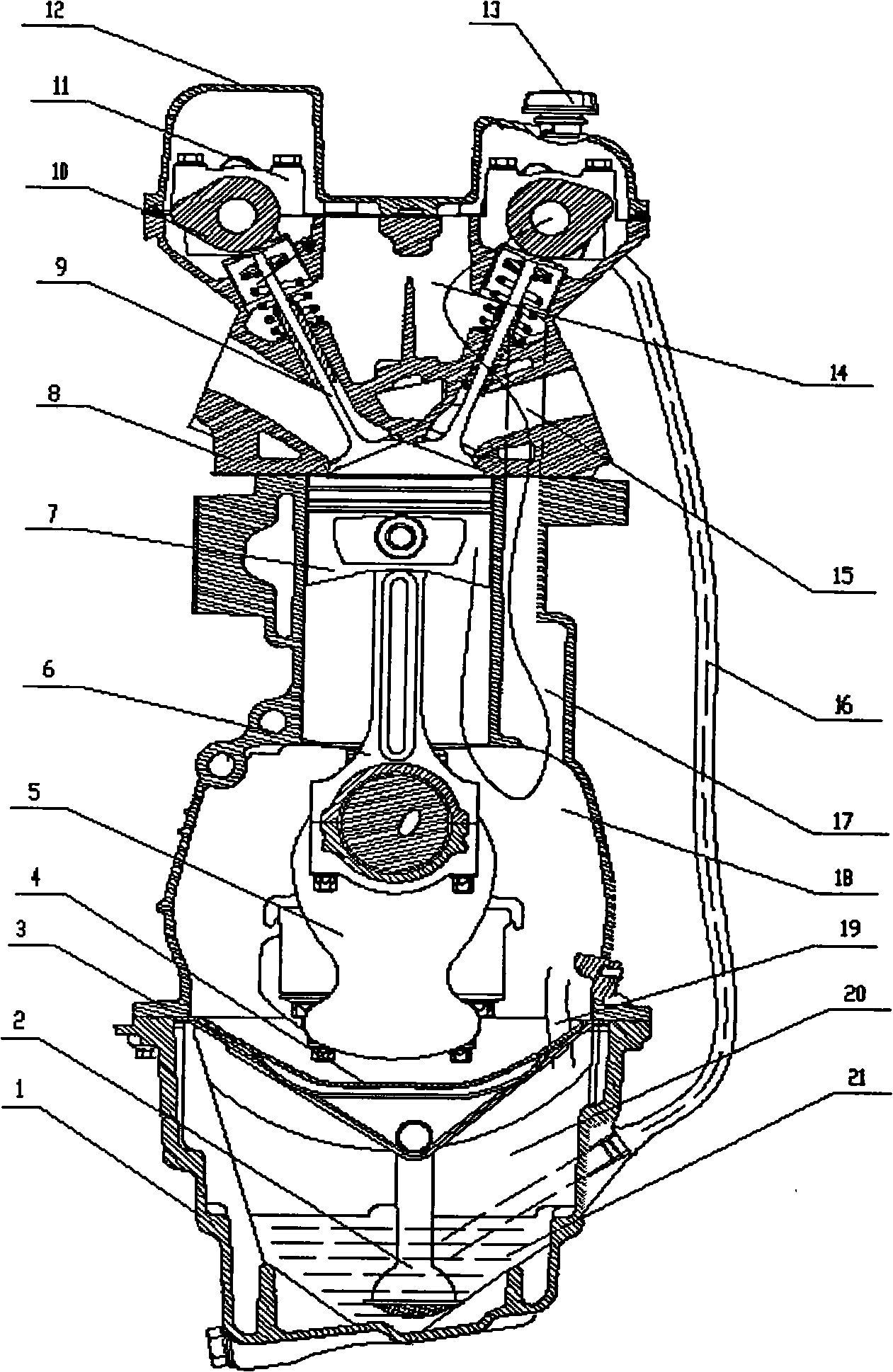

[0013] see figure 1 , the usual internal combustion engine main body structure consists of crankcase 3, crankshaft 5, connecting rod 6, piston 7, camshaft 10, valve train components 9, cylinder head 8 and cylinder head cover 12, oil pan 1, oil filter 2, PCV valve 25 and so on. Wherein, the engine oil pan 1 and the engine oil reflector 4 form the engine oil chamber 20, and there is an oil gas channel 19 passing through the engine oil reflector. Crankcase 18 is formed by crankcase 3, crankshaft 5, connecting rod 6, and piston 7. There is a vent chamber 17 with a small upper opening and a larger lower opening at the crankcase 3 edge. Also there is a ventilation chamber 15 at the cylinder head 8, and at the top of the cylinder head 8, the valve chamber 14 is formed by the valve train element 9, the cylinder head cover 12, and the filler cap 13.

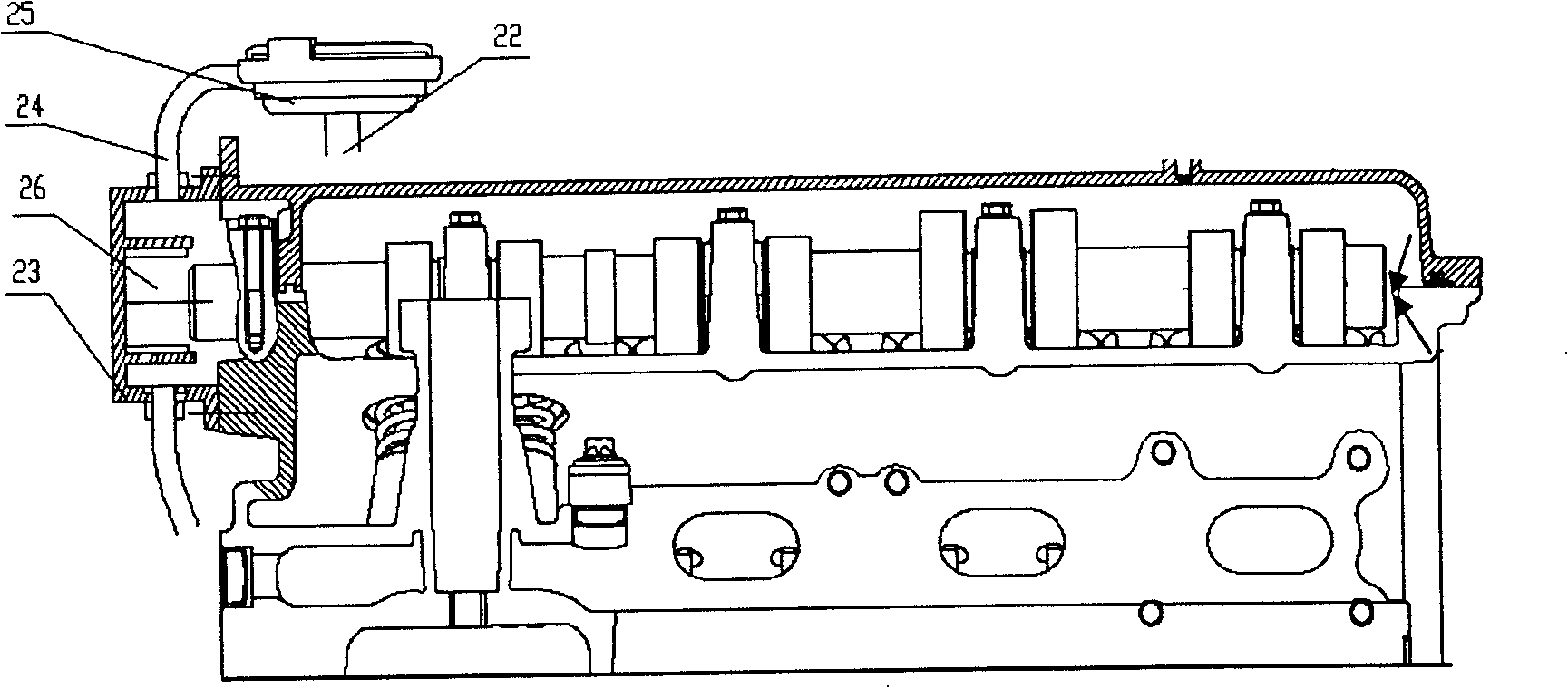

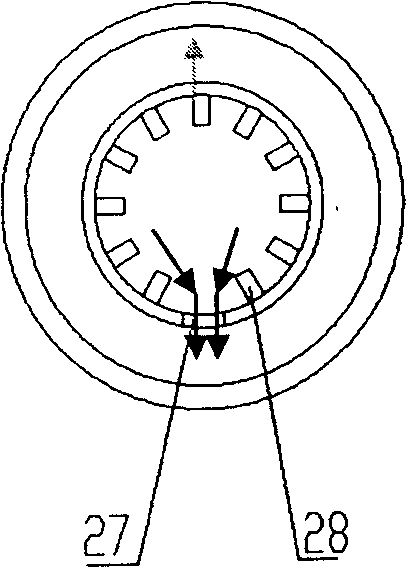

[0014] combine figure 2 and image 3 It can be seen that the crankcase ventilation structure is arranged on the cylinder head cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com