Method for gas liquid separation under oil well and uniform flow gas anchor of multiple sedimentation cups

A gas-liquid separation and iso-flow technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of low separation efficiency, difficulty in improving pump efficiency and output, etc., so as to improve crude oil production and pump efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

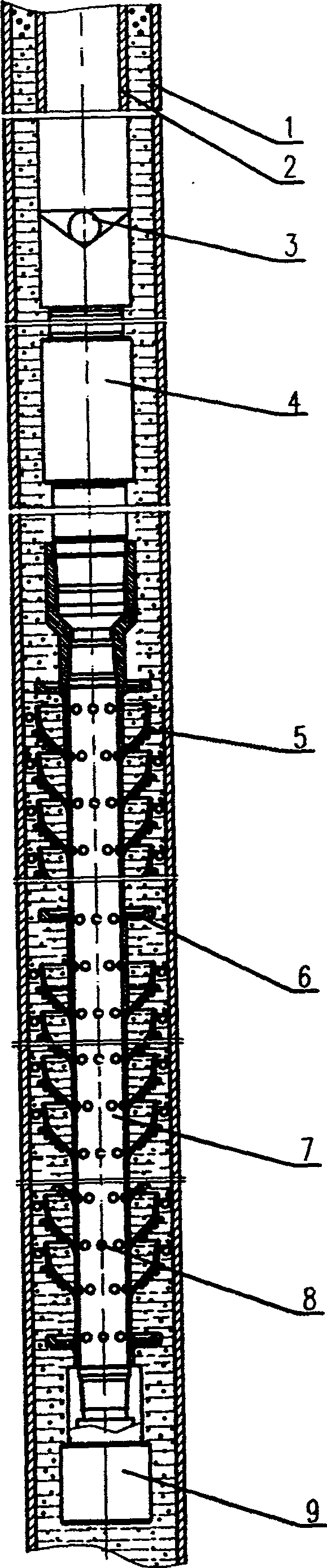

[0015] Referring to the accompanying drawings, the multi-settling cup iso-flow air anchor is composed of a central tube 7, a settling cup 5, a settling cup protection body 6 and a well flushing valve 9; several settling cup protection bodies 6 are fitted on the central tube 7 with gap fit , multiple settling cups 5 are installed between every two settling cup protectors 6, and the outer diameter of the upper tray of the settling cup protecting body 6 is greater than the cup opening diameter of the settling cup 5; the outer contour of the settling cup 5 is streamlined and rising ; The center pipe 7 is uniformly provided with several liquid inlet holes 8 at the position close to the inner bottom of each settling cup 5, and the flow area of the liquid inlet holes 8 is 0.2mm 2 --7mm 2 Between; the lower part of the center pipe 7 is connected with the well flushing valve 9.

[0016] The rising angle of the above-mentioned settling cup 5 forms an angle of 30°-60° with the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com