Multilayer uniform-flow-type coalescence oil-water separator and separation method

An oil-water separator and equal-flow technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as filter clogging, baffle unequal flow, and many sewage settling tanks, so as to increase processing capacity, Increase the effect of saving energy, reducing consumption and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment:

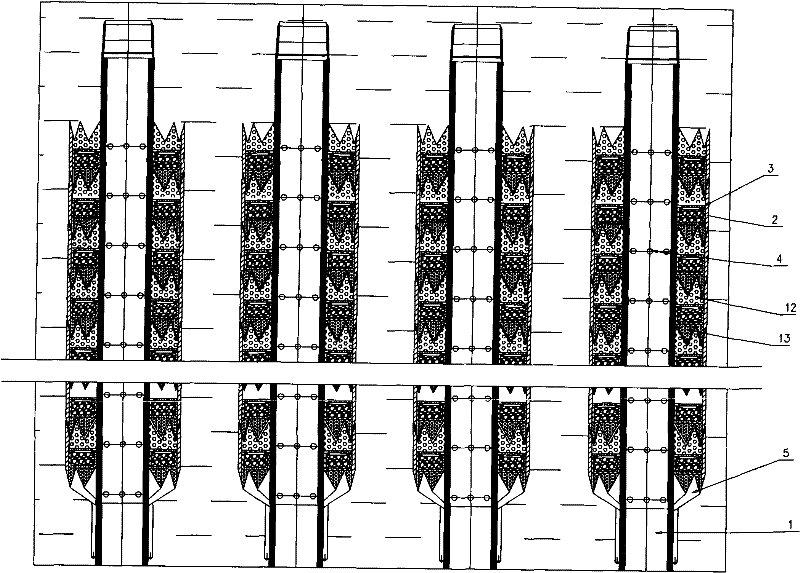

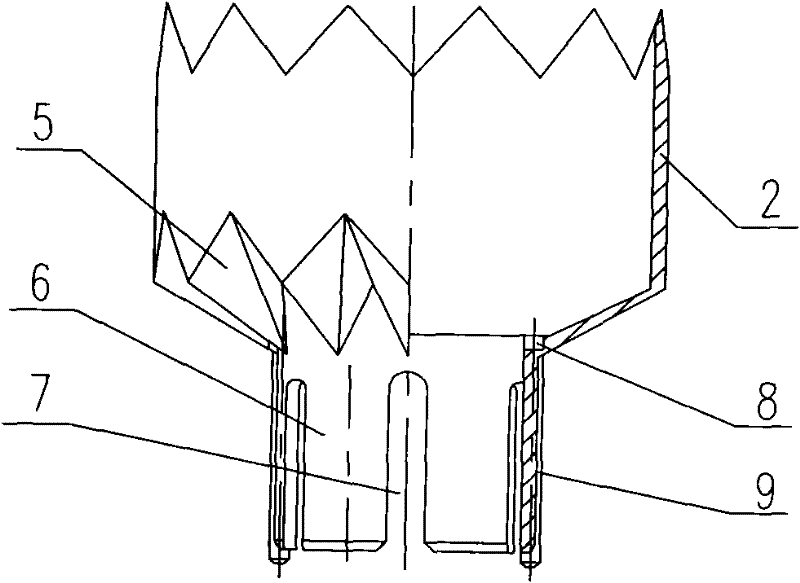

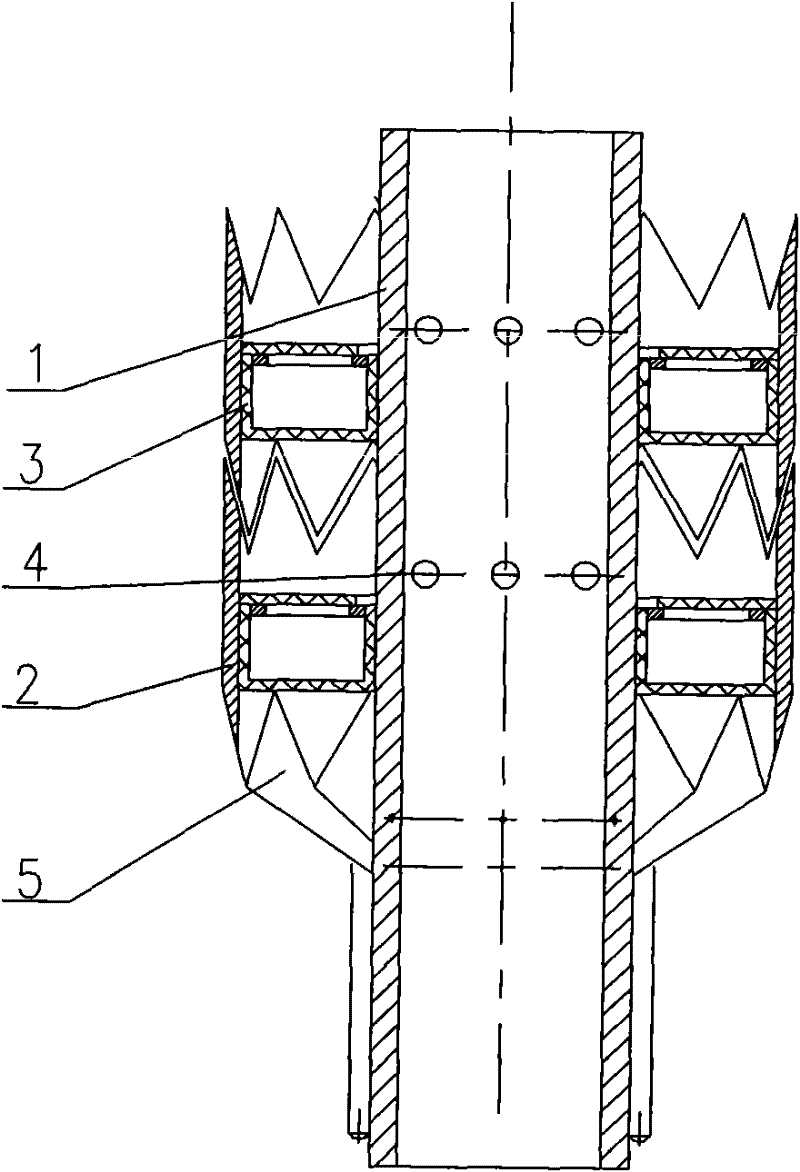

[0018] The multi-layer equal-flow coalescing oil-water separator is composed of multiple sets of center tubes 1, settling cups 2, filter material containers 3 and walnut shell filter materials; multiple sets of center tubes 1 and center tubes 1 are installed in parallel and in series in the settling tank. A plurality of settling cups 2 are installed at equal intervals. There is a gap between the settling cups 2 and the settling cups 2. The bottom surface 5 of the cup body of the settling cup 2 is multi-faceted. Gather to form larger diameter oil droplets, there is an annular space between the cup body of the settling cup 2 and the central pipe 1, and the central pipe 1 corresponding to the annular space has a set of equal-diameter liquid inlet holes 4, and the center of each settling cup 2 corresponds The number of liquid inlet holes 4 opened on the tube 1 is 4-10, and the flow area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com