Air-dried type acrylic ester waterproof paint and preparation method thereof

An acrylate and waterproof coating technology, applied in the coating and other directions, can solve the problem that the sealing wax cannot effectively solve the problems of oxygen inhibition and incomplete curing, and achieves the effect of flexible design formula, good film performance and good curing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

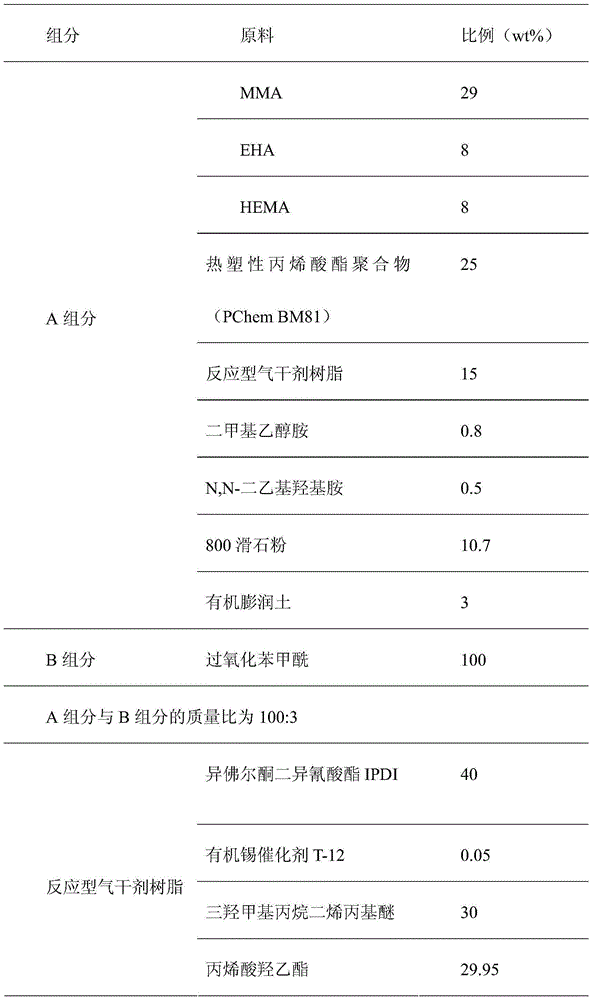

[0031] An air-drying acrylic waterproof coating is composed of component A and component B, and its formula composition is shown in Table 1.

[0032] Table 1 Embodiment 1 coating formula

[0033]

[0034] The preparation method of the reactive air-drying agent resin in embodiment 1:

[0035] Under the protection of nitrogen, accurately weigh 40g of IPDI aliphatic isocyanate, 0.05g of catalyst T-120.05g, 30g of trimethylolpropane diallyl ether and 29.95g of hydroxyethyl acrylate, and add IPDI and catalyst to a closed dispersion tank , heated and stirred until the system temperature was 40° C., slowly added dropwise weighed trimethylolpropane diallyl ether, and the system was heated to 60-65° C. and maintained for 3 hours. Then add the weighed hydroxyethyl acrylate, stir to raise the temperature to 80°C and keep it for 2 hours; then lower the temperature to below 60°C, filter and seal the package to obtain the reactive air-drying agent resin.

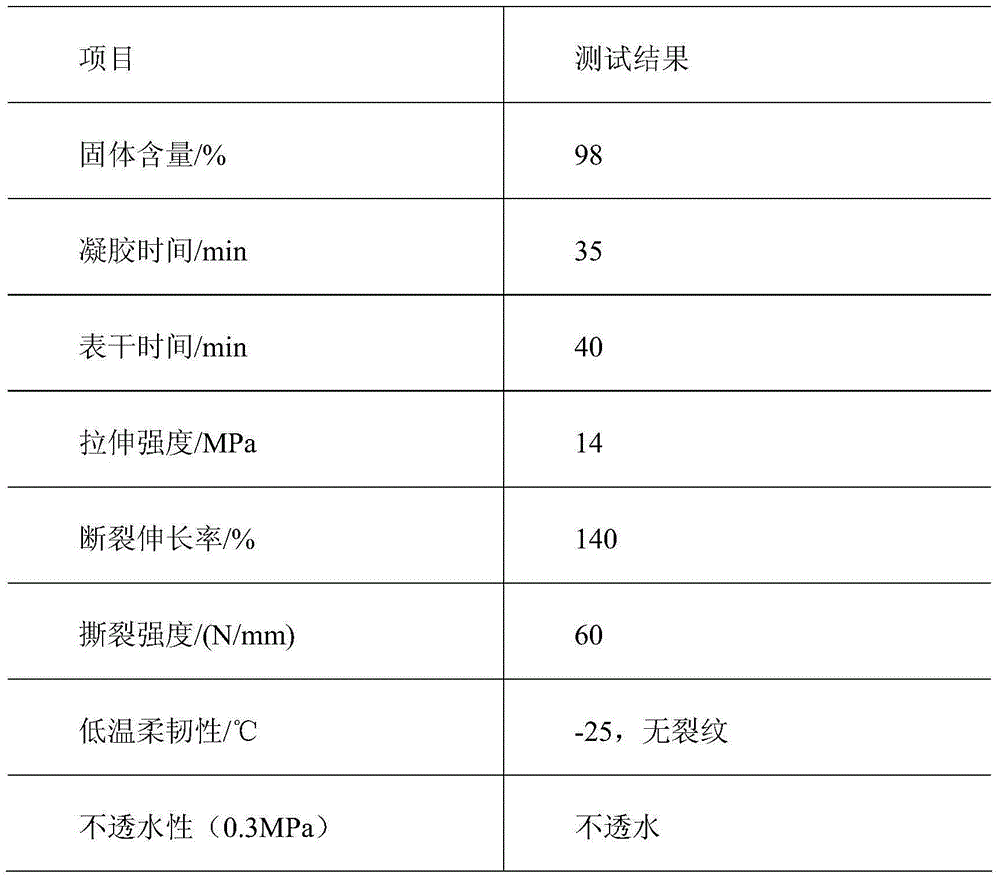

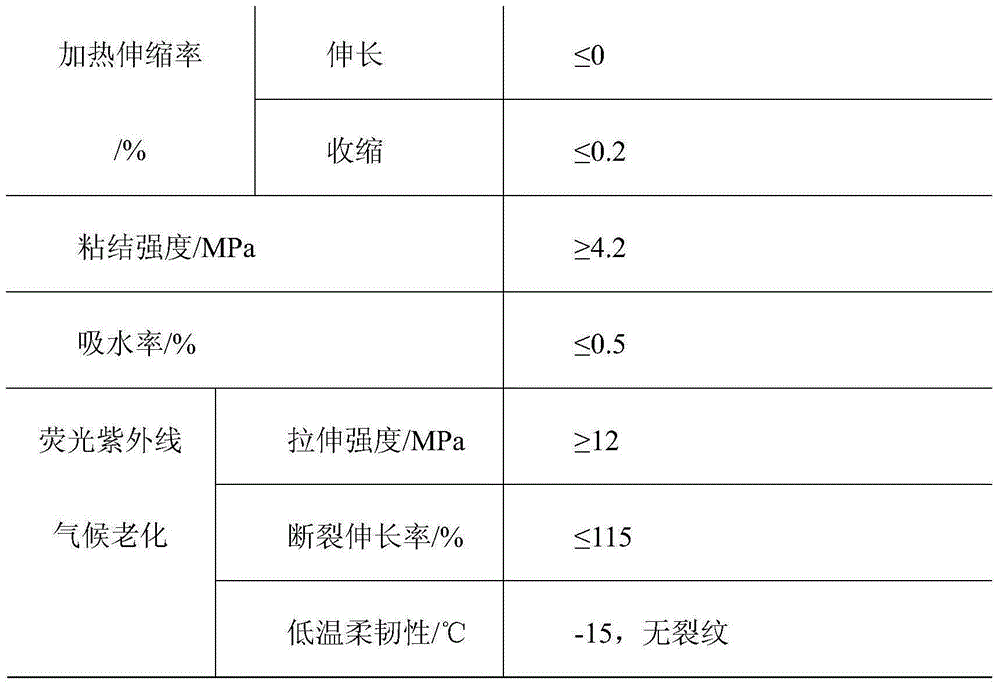

[0036] Embodiment 1 performan...

Embodiment 2

[0051] An air-drying acrylic waterproof coating is composed of component A and component B, and its formula composition is shown in Table 5. Table 5 Embodiment 2 coating formula

[0052]

[0053]

[0054] The preparation method of the reactive air-drying agent resin in embodiment 2:

[0055] Under the protection of nitrogen, accurately weigh 38g of IPDI aliphatic isocyanate, organic bismuth catalyst Bi16100.1g, 32g of diethylene glycol monoallyl ether and 29.9g of hydroxypropyl acrylate, and add IPDI and catalyst to a closed dispersion tank , heated and stirred until the system temperature was 40° C., slowly added dropwise weighed diethylene glycol monoallyl ether, and the system was heated to 60-65° C. and maintained for 3 hours. Then add the weighed hydroxypropyl acrylate, stir to raise the temperature to 80°C and keep it for 2 hours; then lower the temperature to below 60°C, filter and seal the package to obtain the reactive air-drying agent resin.

Embodiment 3

[0064] An air-drying acrylic waterproof coating is composed of component A and component B, and its formula composition is shown in Table 7.

[0065] Table 7 Embodiment 3 coating formula

[0066]

[0067]

[0068] The preparation method of the reactive air-drying agent resin in embodiment 3:

[0069] Under the protection of nitrogen, accurately weigh 45g of IPDI aliphatic isocyanate, bismuth-zinc mixed catalyst Zb10010.1g, pentaerythritol triallyl ether 40g, butyl acrylate 9.9g and hydroxyethyl methacrylate 5g and add IPDI and catalyst Put it into a closed dispersing tank, heat and stir until the system temperature is 40°C, slowly add the weighed pentaerythritol triallyl ether dropwise, the system temperature rises to 60-65°C and maintains for 3 hours. Then add weighed butyl acrylate and hydroxyethyl methacrylate, stir to raise the temperature to 80°C and keep it for 2 hours; then lower the temperature to below 60°C, filter and seal the package to obtain the reactive ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com