Packaging structure and packaging method of organic electroluminescent device

A technology for electroluminescent devices and packaging structures, which is applied in the fields of electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of loss of gettering ability, damage to organic light-emitting materials, degradation of device life and photoelectric performance, etc. Effects of performance and life, improved reliability, improved mechanical strength and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

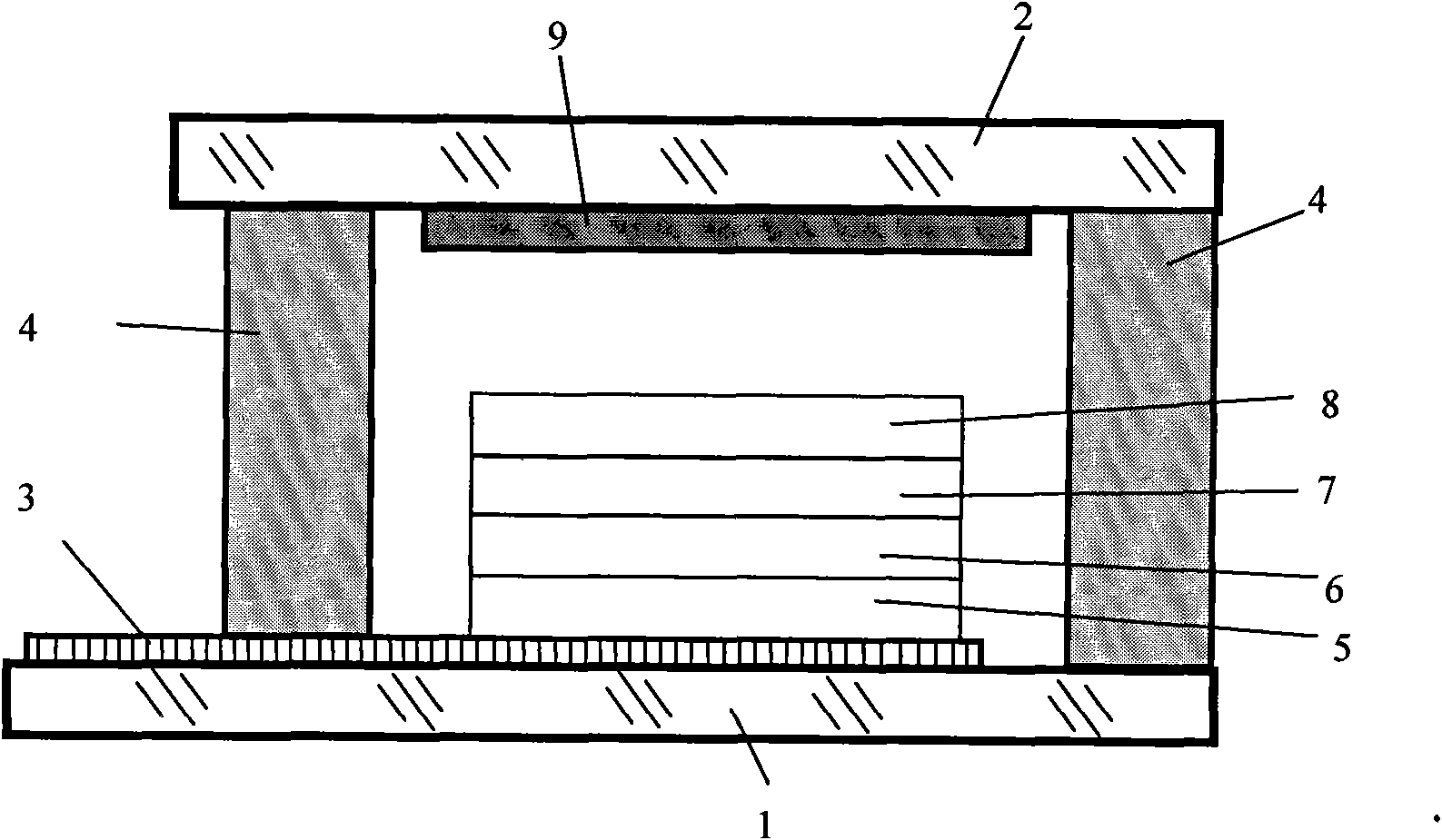

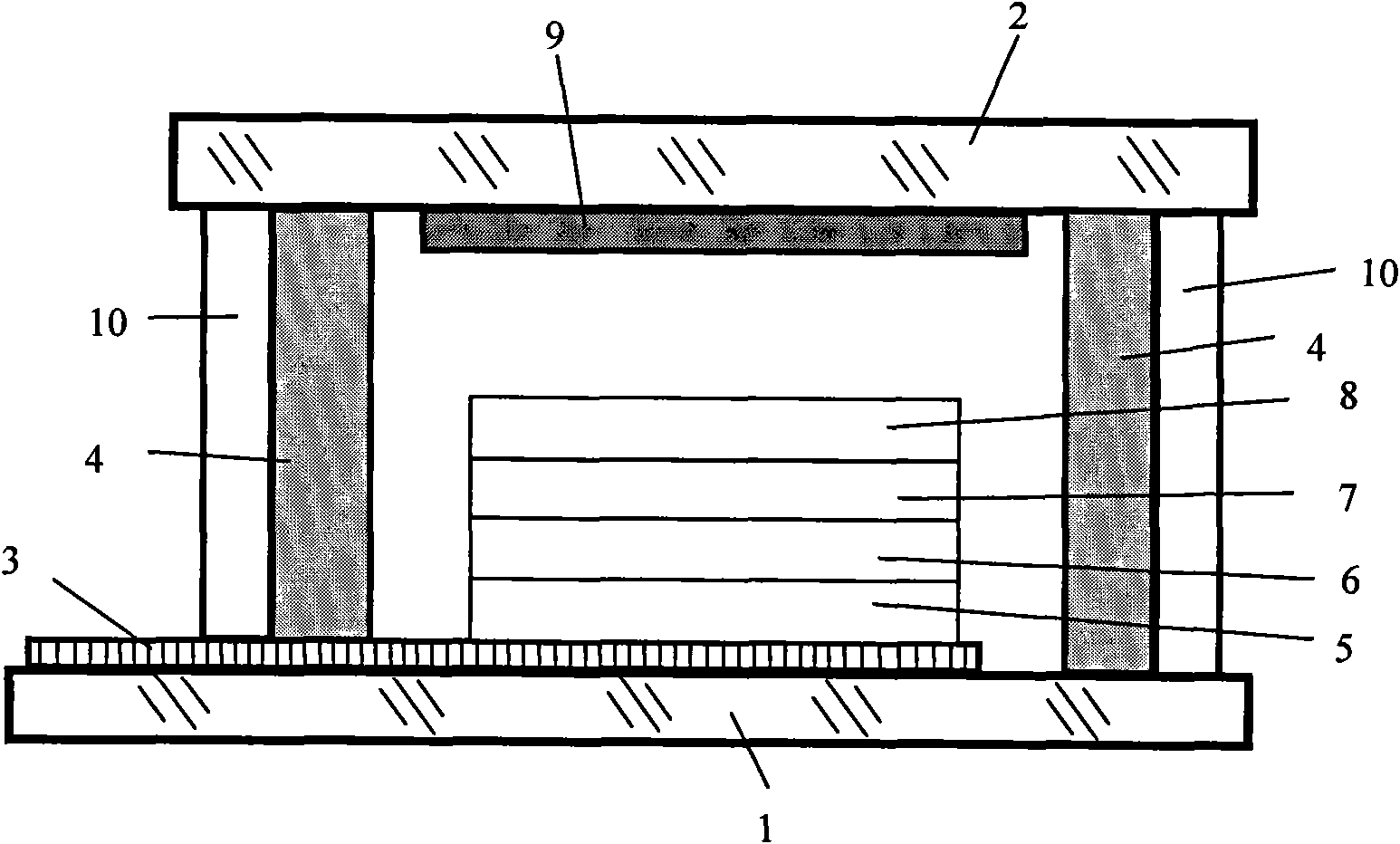

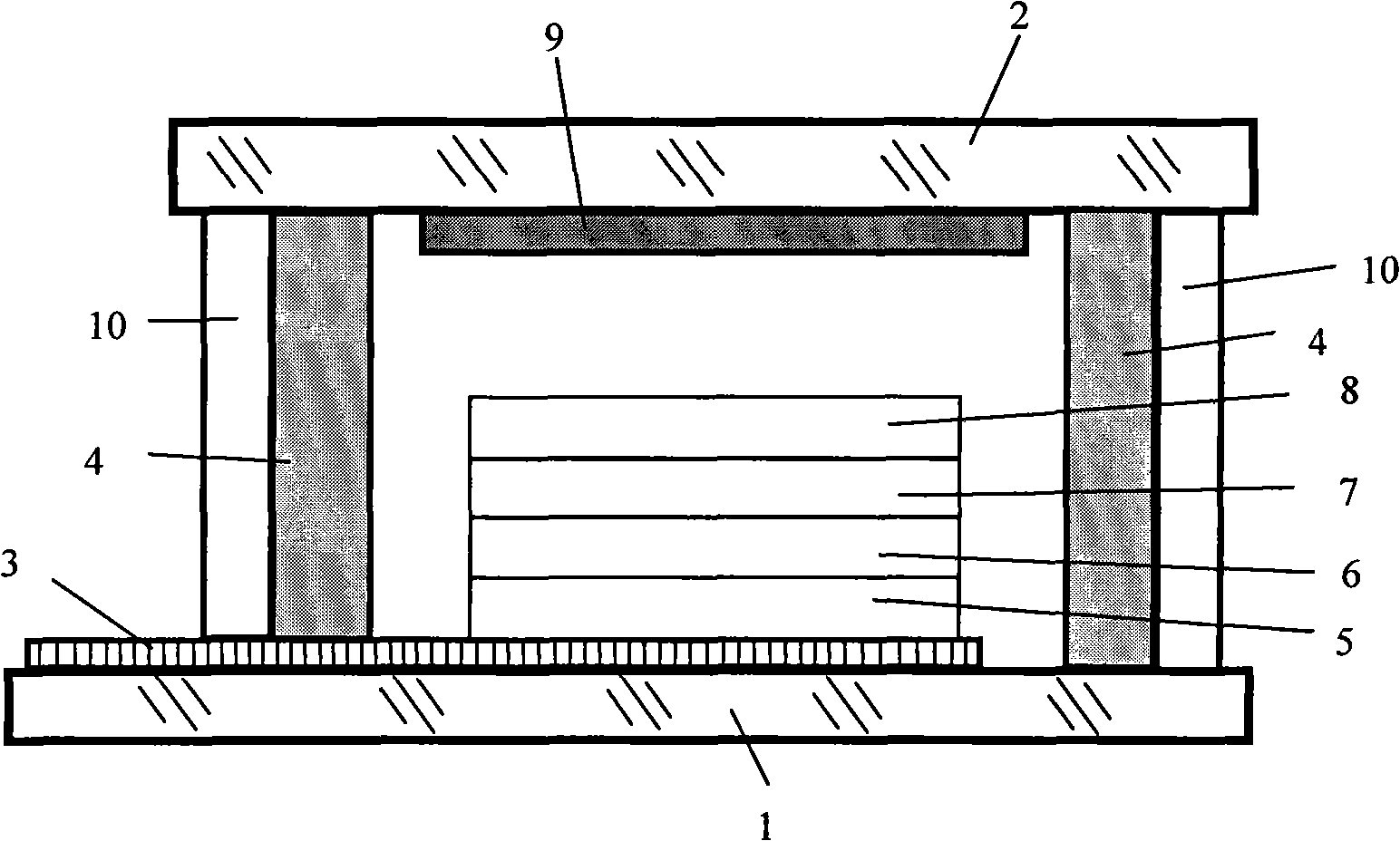

[0035] The present invention will be further described below in conjunction with accompanying drawing:

[0036] The encapsulation structure of the organic electroluminescent device uses glass or flexible transparent materials as the bottom plate and the cover plate. A transparent conductive film electrode layer and each organic light-emitting functional layer are fabricated on the base plate, and then sealed with the cover plate, and the sealing material is vacuum sealing wax. Vacuum sealing wax has good barrier properties, and its water vapor and oxygen permeability are an order of magnitude lower than that of epoxy resin, which can significantly reduce the penetration of water vapor and oxygen through the sealing layer of organic light-emitting devices and improve the life of organic light-emitting devices . The temperature required for vacuum wax sealing is 80-100°C, which is lower than the glass transition temperature of general organic light-emitting functional layer mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com