Method for processing and manufacturing environmentally friendly aggrandizement wood floor by vacuum ammonia

An environmentally friendly technology for laminate flooring, applied in the jointing of wooden veneers, chemical instruments and methods, wood treatment, etc., can solve problems such as technical defects and application restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

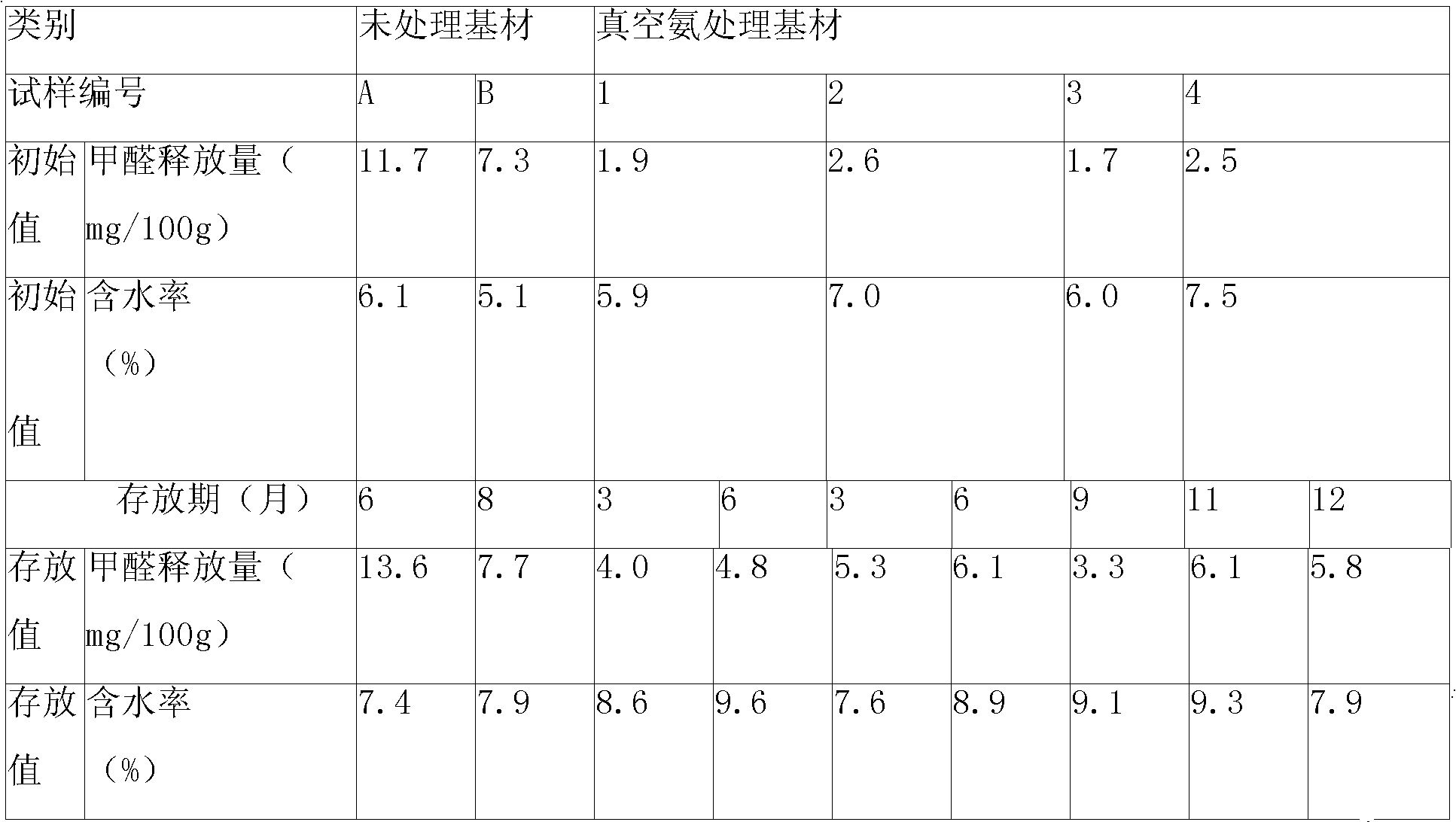

Embodiment 1

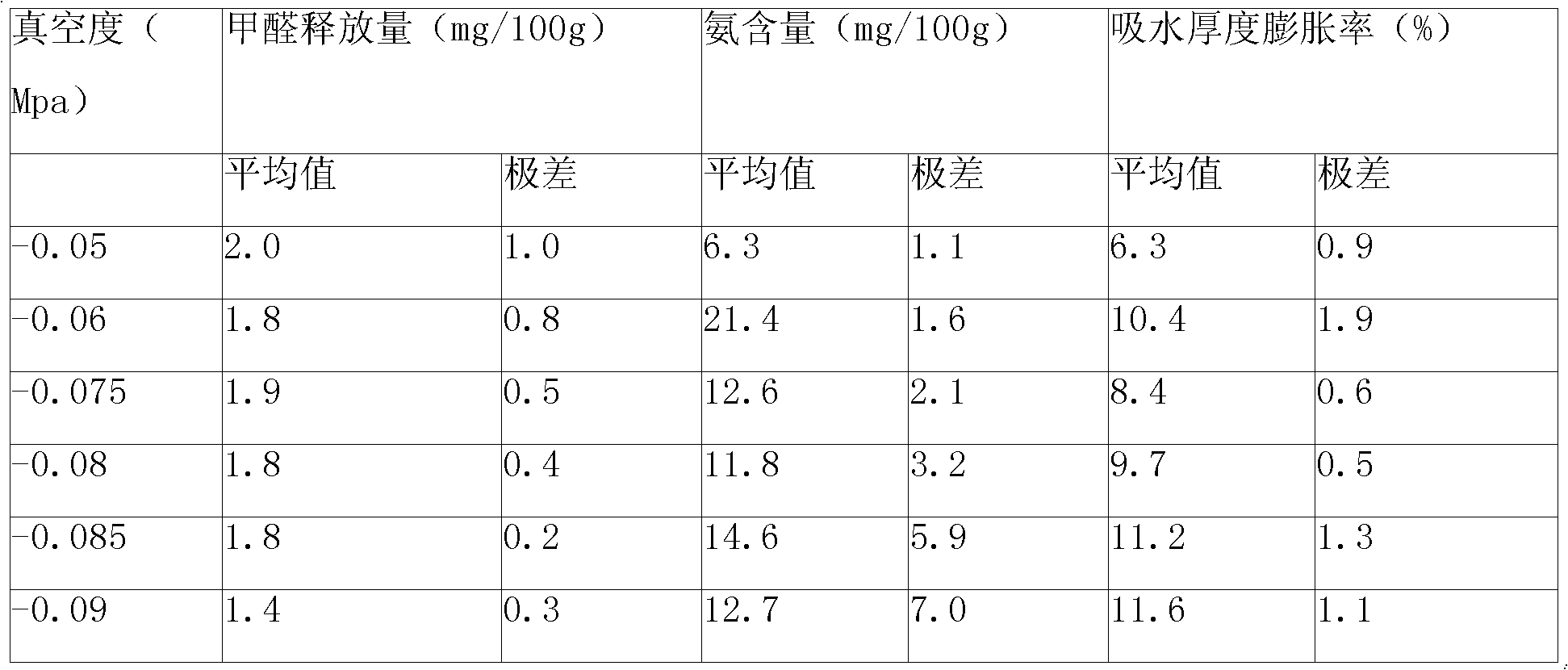

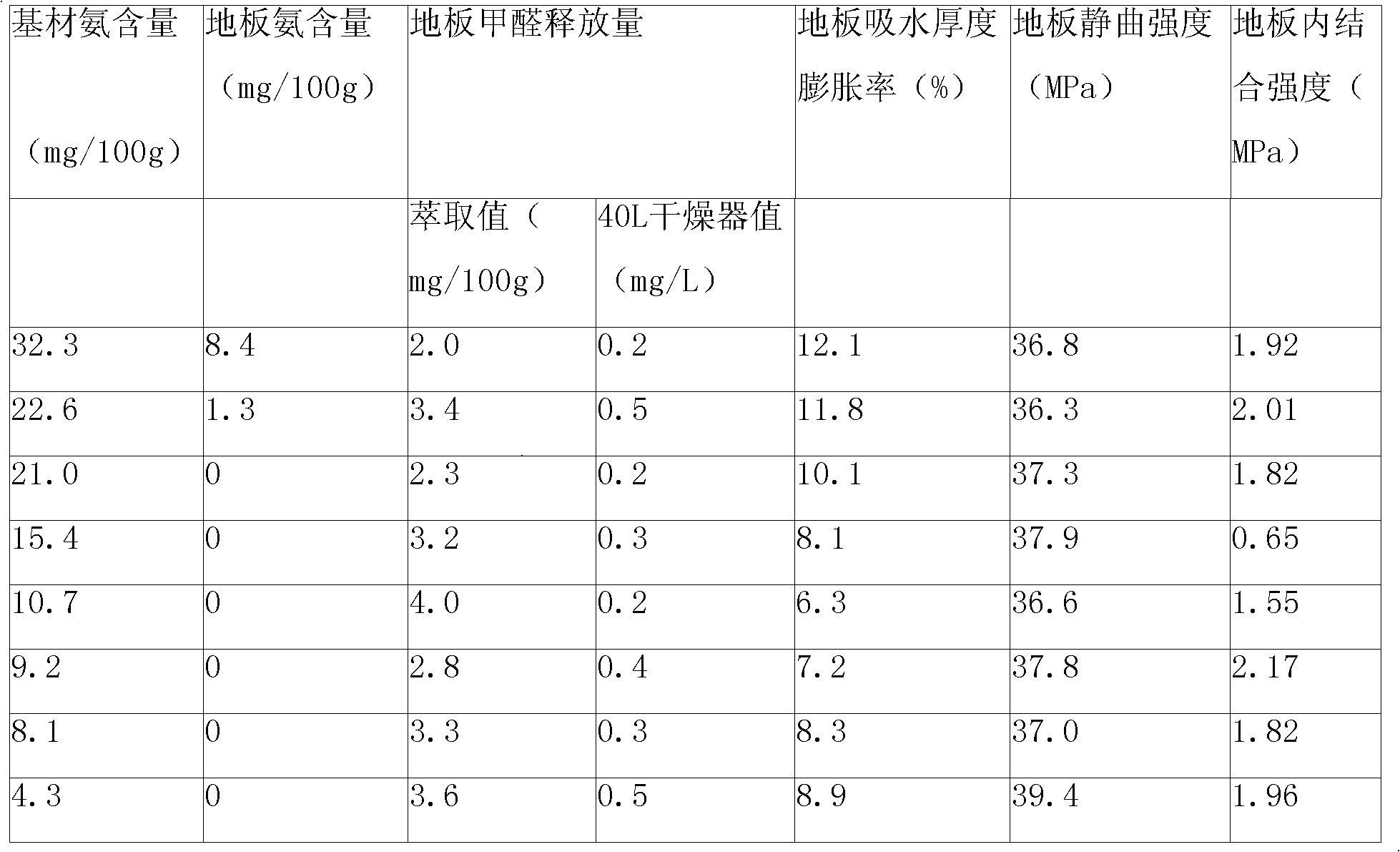

[0049]A batch of E with a formaldehyde emission of 24.9mg / 100g 2 The first-grade floor base material is installed with a grid frame with fiberboard, put it into a closed vacuum box, turn on the vacuum pump to make the vacuum degree in the box reach -0.06MPa, and then feed the unit plate consumption of 1.42kg / m into the box 3 When the liquid ammonia is vaporized and completely absorbed in the fiberboard, release the vacuum, open the box door, take out the board with an ammonia content of 14.8mg / 100g, and then mix impregnated wear-resistant paper, decorative paper, and balance paper with it Assemble the billet, heat press it in a press with a temperature of 195°C and a pressure of 7.5MPa for 40 seconds, cut the formed board into semi-finished floor products of a certain specification, and make it through health balance, slotting, wax sealing, and packaging. Environmentally friendly laminate flooring with formaldehyde emission perforation extraction value of 2.8mg / 100g, 40L dryer...

Embodiment 2

[0051] A batch of E with a formaldehyde emission of 17.8mg / 100g 2 The first-grade floor base material is installed with a grid frame with fiberboard, put it into a closed vacuum box, turn on the vacuum pump to make the vacuum degree in the box reach -0.07MPa, and then feed the unit plate consumption of 0.96kg / m 3 When the liquid ammonia is gasified and completely absorbed in the fiberboard, release the vacuum, open the box door, take out the board with an ammonia content of 10.7mg / 100g, and then mix impregnated wear-resistant paper, decorative paper, and balance paper with it Assemble the billets, heat press them in a press with a temperature of 190°C and a pressure of 5.0MPa for 35 seconds, cut the formed boards into semi-finished floor products of certain specifications, and make them through health balancing, slotting, wax sealing, and packaging. Environmentally friendly laminate flooring with formaldehyde emission perforation extraction value of 2.5mg / 100g, 40L dryer value...

Embodiment 3

[0053] A batch of E with a formaldehyde emission of 9.8mg / 100g 2 The first-grade floor base material is installed with a grid frame with fiberboard, put it into a closed vacuum box, turn on the vacuum pump to make the vacuum degree in the box reach -0.08MPa, and then pass it into the unit plate with a consumption of 0.67kg / m 3 When the liquid ammonia is vaporized and completely absorbed in the fiberboard, release the vacuum, open the box door, take out the board with an ammonia content of 5.1mg / 100g, and then put impregnated wear-resistant paper, decorative paper, and balance paper with it Assemble the billet, hot press in a press with a temperature of 185°C and a pressure of 2.5MPa for 30 seconds, cut the formed board into semi-finished floor products of a certain specification, and make it through health balancing, slotting, wax sealing, and packaging. Environmentally friendly laminate flooring with formaldehyde emission perforation extraction value of 2.0mg / 100g, 40L dryer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com