Preserved egg mechanical wax-spraying type wax-sealing method and device

A wax-spraying, preserved egg technology is applied in the fields of preservation, preserved egg storage, and packaging, which can solve the problems of unsatisfactory sealing wax quality, high paraffin consumption, and easy occurrence of fried eggs, etc., to improve the working conditions of workers, low paraffin consumption, The effect of low breakage rate of preserved eggs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for mechanically pouring wax on preserved eggs, the concrete steps comprising:

[0040] A. Add solid food-grade paraffin to the wax melting box, turn on the heating tube switch of the wax melting box, connect the heating tube of the wax melting box installed at the bottom of the wax melting box, and melt the paraffin to a liquid state through the heating tube of the wax melting box. The heating temperature is 95°C or 98°C or 101°C or 104°C or 107°C or 110°C; then turn on the forward rotation switch of the pump, start the self-heating and heat preservation gear pump, and the self-heating and heat preservation gear pump will pump the melted paraffin into the wax spray box . The liquid paraffin is further heated in the wax spraying box by the heating pipe of the wax spraying box, and the heating temperature is maintained at 100°C or 102°C or 105°C.

[0041] B. Turn on the switch of the main drive motor, start the main drive motor, place the preserved eggs between...

Embodiment 2

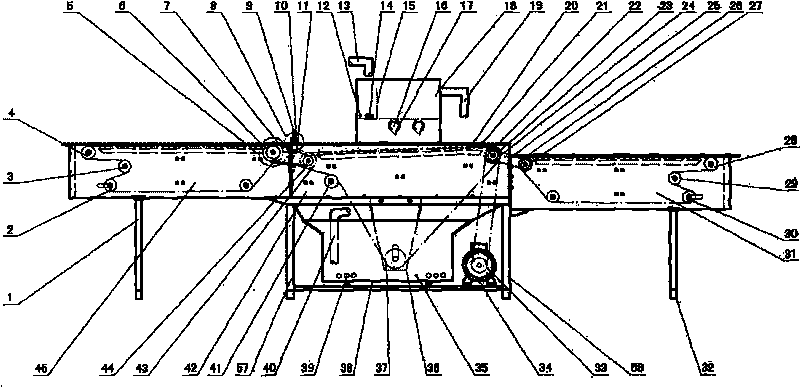

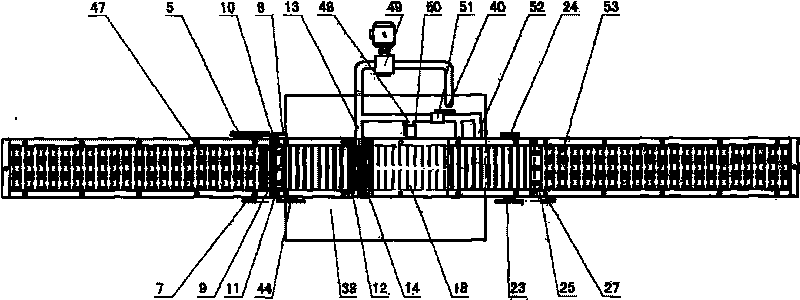

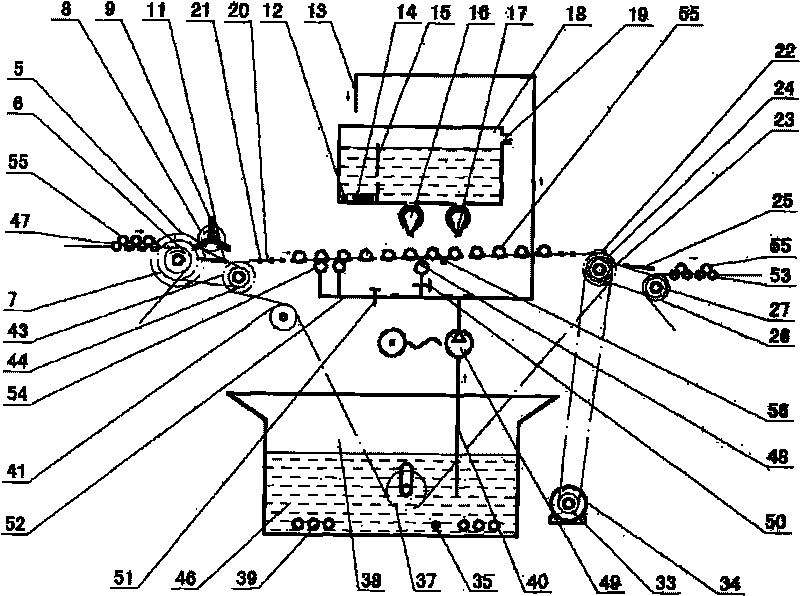

[0046] A device for realizing the above-mentioned mechanical wax-spraying wax sealing method, including a chain transmission device composed of a chain and a sprocket, a wax melting device, a wax pouring device, an egg holding device, a feeding device, a feeding device, a frame, an auxiliary Devices and wax liquid delivery piping system.

[0047]The chain transmission of the present embodiment all uses sleeve roller chain transmission. Its transmission route is: the main drive driving sprocket 33 rotates on the main drive motor 34 shaft, directly driven by the main drive motor 34, the main drive motor 34 is connected with a frequency converter 59, and is controlled by the main drive motor switch 61 The opening and closing of the main drive motor 34 can change the rotating speed of the main drive motor 34 through the frequency converter 59; through the chain transmission, the main drive driving sprocket 33 drives the main drive driven sprocket 24; the main drive driven sprocket...

Embodiment 3

[0057] The difference between embodiment 3 and embodiment 2 has:

[0058] Use different wax pouring ports to spray wax and seal wax. The wax pouring port is directly opened by the wax spraying pipe, and the liquid paraffin flow rate of the wax spraying pipe is directly adjusted through the wax spraying pipe control valve to control the liquid state of the wax spraying port. The purpose of paraffin flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com