Method for preparing cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent

A dimethyl diallyl ammonium chloride, cationic technology, used in dyeing, textiles and papermaking, etc., can solve the problem of incompatibility between hand feeling and color fastness, slow development of aldehyde-free color-fixing agents, and poor color fastness Low wet rubbing fastness and other problems, to achieve the effect of improving color fastness, good elasticity, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific synthesis operation method is as follows:

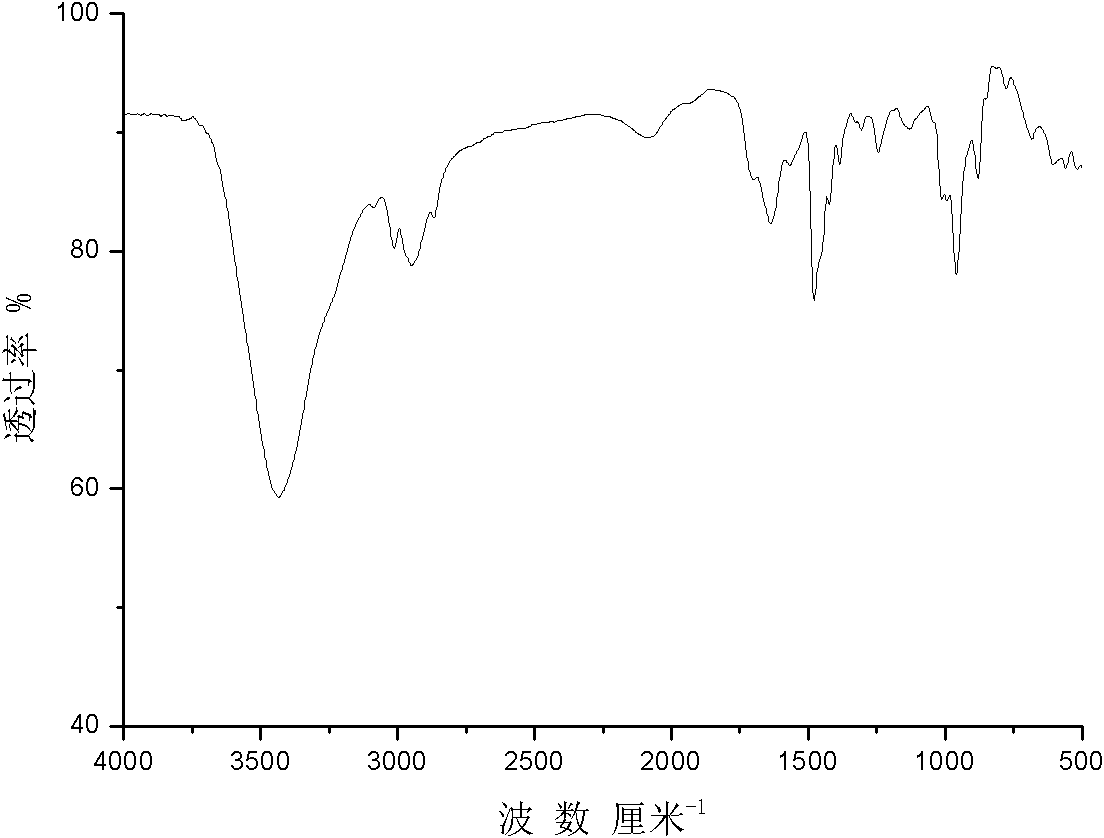

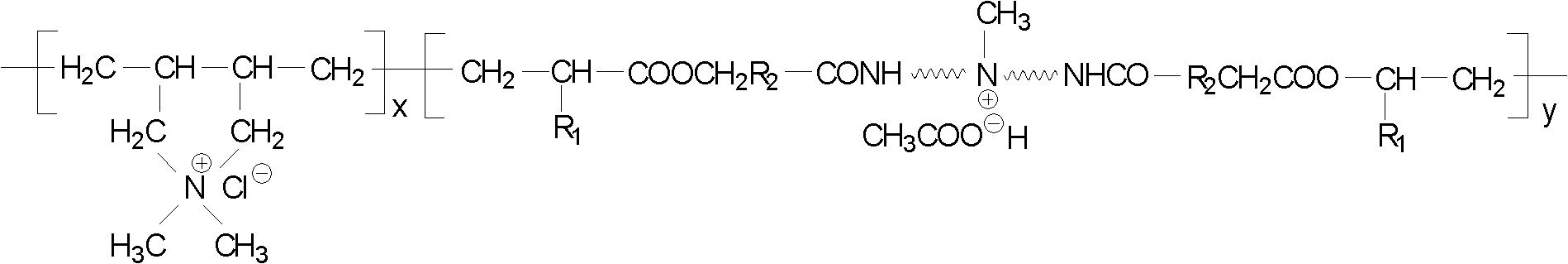

[0041] 1. Preparation of vinyl-terminated cationic polyurethane emulsion

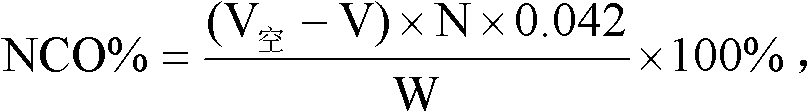

[0042] Put 100kg of polyoxypropylene diol into the reactor, vacuum dehydrate at 100-120°C for 2h; then cool down to 50-60°C, add 35kg of toluene diisocyanate and 11kg of hydrophilic monomer N-methyldiethanolamine, at 70°C -75°C heat preservation reaction for 2h; under the condition of 65-70°C, slowly drop N-methyldiethanolamine butanone solution into the system, wherein the mass of N-methyldiethanolamine is 1.5kg, and the mass of butanone is 8kg, continue to react at 70-75°C after the dropwise addition, until the reaction stops when the NCO% is 2.5%, then add 8.5kg of β-hydroxyethyl acrylate and 0.1kg of inhibitor hydroquinone, at 80°C Insulation reaction 2h. In the reaction process, add methyl ethyl ketone 80kg when viscosity is bigger. After the reaction, cool down to 60°C, add 6.25kg of neutralizing agent acetic acid, stir for 30 minu...

Embodiment 2

[0048] The specific synthesis operation method is as follows:

[0049] 1. Preparation of vinyl-terminated cationic polyurethane emulsion

[0050] Put 100kg of polyoxyethylene diol into the reactor, vacuum dehydrate at 100-120°C for 2 hours; then cool down to 50-60°C, add 45kg of 1,6-hexamethylene diisocyanate and hydrophilic monomer N-formazol 16kg of N-methyldiethanolamine, heat preservation reaction at 75-80°C for 2h; cool down to 70°C, slowly add N-methyldiethanolamine butanone solution dropwise into the system, wherein the mass of N-methyldiethanolamine is 2.2kg, butanone The quality of ketone is 8kg, continues to react at 75-80 ℃ after finishing dropping, until NCO% is 3.2% when reaction stops, add acrylate-beta-hydroxypropyl ester 9kg and stopper Hydroquinone 0.1kg then, in The reaction was incubated at 80°C for 2h. In the reaction process, add methyl ethyl ketone 100kg when viscosity is bigger. After the reaction, cool down to 60°C, add 7kg of neutralizing agent acet...

Embodiment 3

[0056] The specific synthesis operation method is as follows:

[0057] 1. Preparation of vinyl-terminated cationic polyurethane emulsion

[0058] Put 100kg of polyoxypropylene-oxyethylene diol into the reactor, vacuum dehydrate at 100-120°C for 2 hours; then cool down to 50-60°C, add 50kg of toluene diisocyanate and 14kg of hydrophilic monomer N-methyldiethanolamine , keep the reaction at 70-80°C for 2h; cool down to 70°C, slowly add N-methyldiethanolamine butanone solution dropwise to the system, wherein the mass of N-methyldiethanolamine is 2kg, and the mass of butanone is 8kg After the dropwise addition, continue to react at 70-75°C until the reaction stops when the NCO% is 4.1%, then add 9.5kg of methacrylate-β-hydroxyethyl ester and 0.1kg of inhibitor hydroquinone, Under the insulation reaction for 2h. After the reaction, cool down to 60°C, add 9.1kg of neutralizing agent acetic acid, stir for 45 minutes, and add 300kg of water under high-speed stirring at 1400 rpm to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com