Novel composite flooring, mold thereof and processing method

A composite floor, a new type of technology, applied in the direction of elastic floor, building, building structure, etc., can solve the problems of easy scratches on the surface of bamboo and wood floor, no moth-proof flame-retardant performance, no moisture-proof, etc., to improve the safety of use , high performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

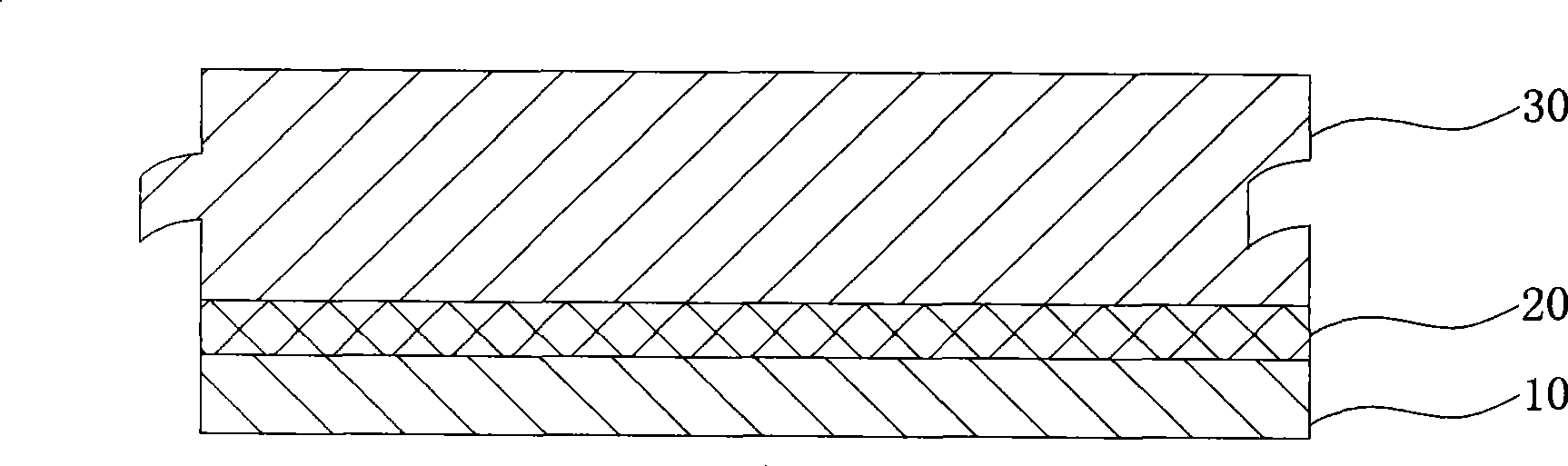

[0016] Such as figure 1 As shown, the base layer 10 of the composite floor is a plastic wood board, the surface layer 30 is a solid wood board, and an elastic layer 20 is arranged between the base layer 10 and the surface layer 30 .

[0017] The wood-plastic board is a board made of wood-plastic composite material, which is made of natural wood fiber and sawdust, wood chips, bamboo chips, rice husk, wheat straw, soybean hulls, peanut shells, bagasse, cotton straw, etc. A composite material made of plant fiber as the main raw material and a small amount of plastic resin. This kind of plastic wood material has the advantages of water resistance, moisture resistance, no moth, no fungus growth, acid and alkali resistance, non-toxicity, no pollution, convenient processing, complete recycling, and no secondary pollution. Therefore, the present invention not only solves the problems of warping and crack deformation of the solid wood floor, but also retains the shape structure and ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com