Vacuum freeze drying puffing processing method of fig

A technology of vacuum freeze-drying and processing method, which is applied in the field of vacuum freeze-drying and puffing processing of figs, can solve the problems of affecting product sensory evaluation, short shelf life of figs, and high drying energy consumption, and achieves complete appearance, good crispness, and drying energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

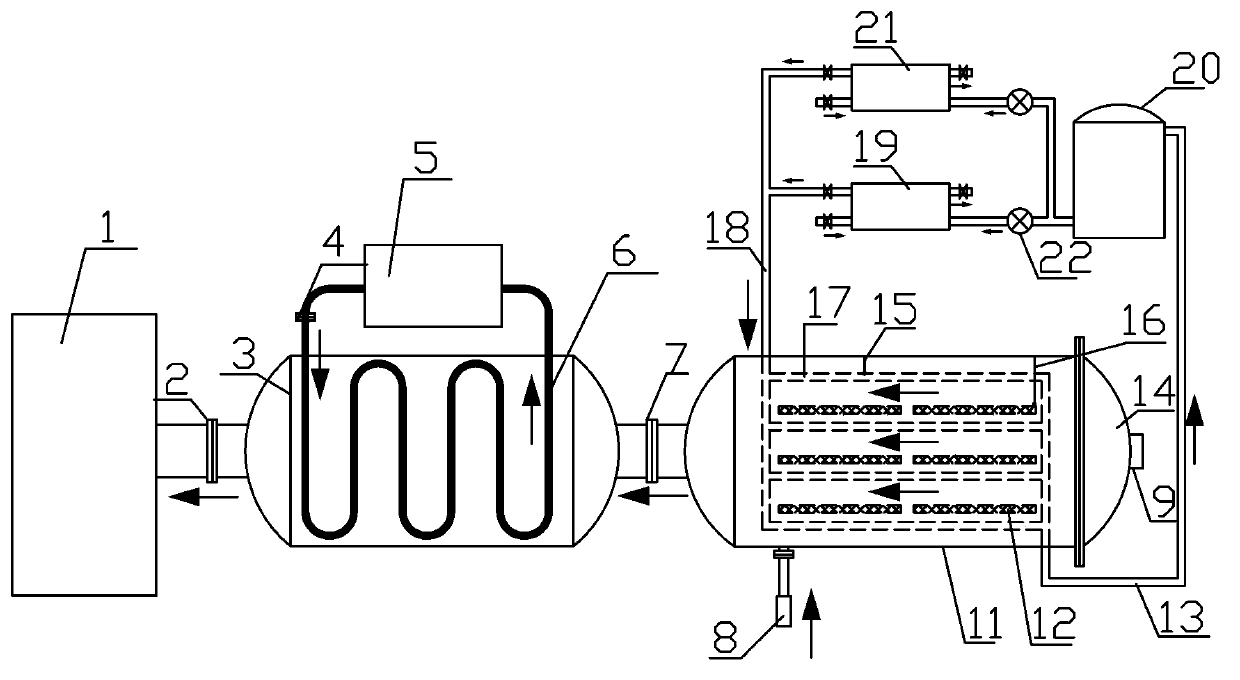

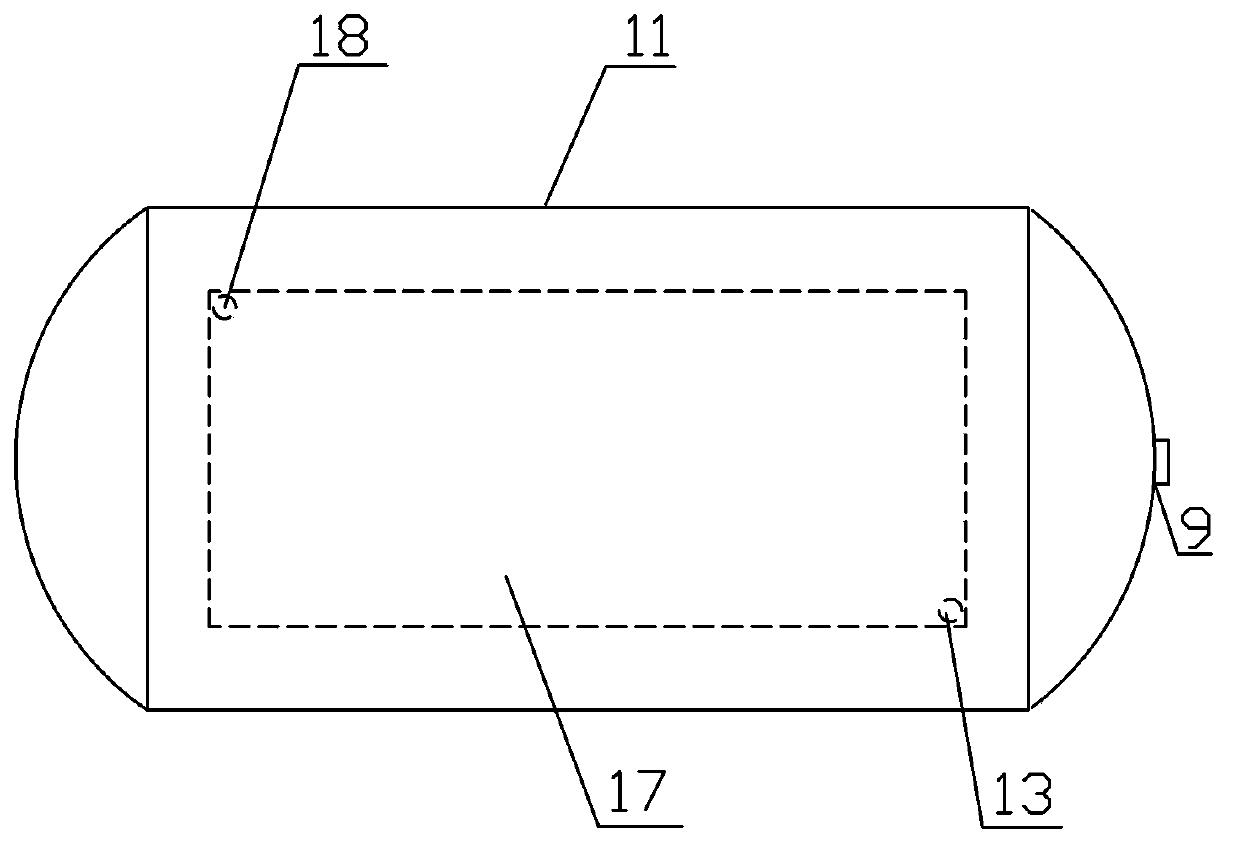

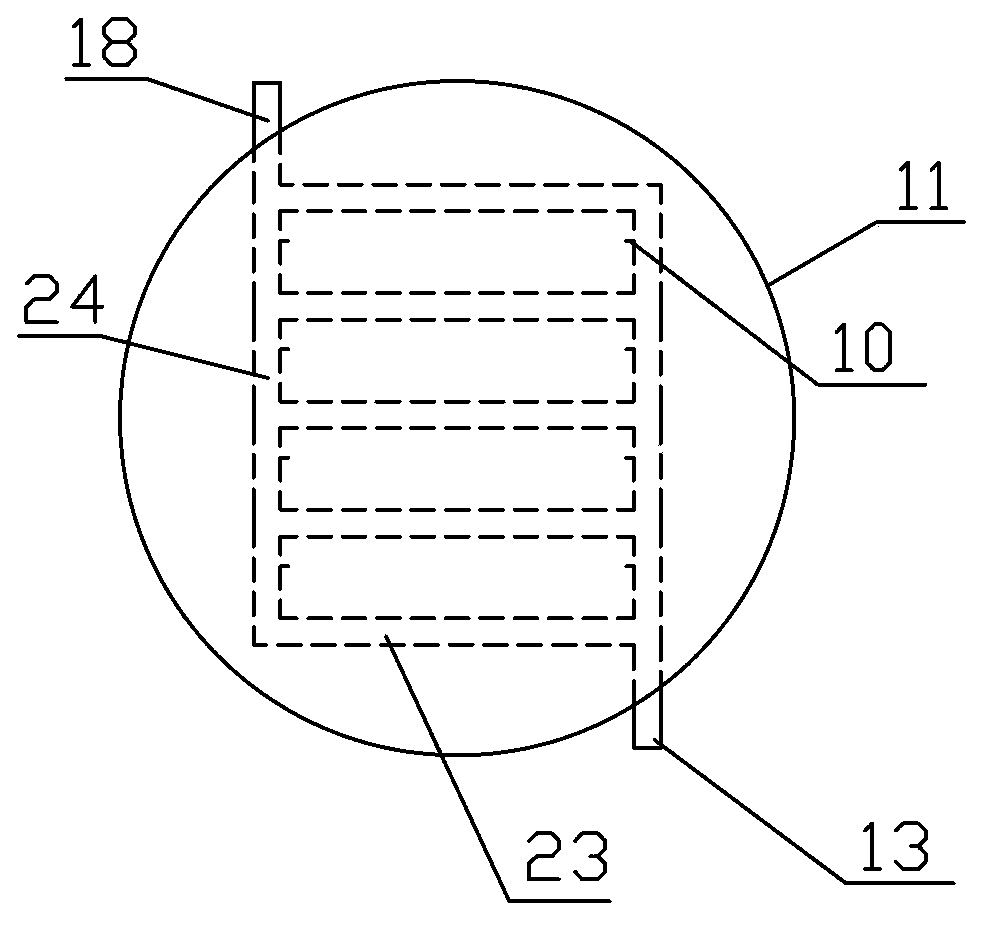

[0023] Refer to the attached figure 1 to attach Figure 4 The vacuum freeze-drying and puffing processing method of a kind of fig of the present invention is described in detail below.

[0024] A vacuum freeze-drying and puffing processing method of figs according to the present invention comprises the following steps: (1) raw material pretreatment: fresh figs are subjected to inspection, cleaning and peeling treatment;

[0025] (2) Spread the processed raw materials into a single layer, evenly distribute them on the material tray 12, put them into the quick-freezing machine, and perform quick-freezing at -40°C for 4-6 hours to ensure that the water in the figs is completely frozen;

[0026] (3) Vacuum freeze-expansion drying by vacuum freeze-expansion dryer:

[0027] The quick-frozen figs are put into the expansion tank 11 together with the material tray 12, placed on the bracket 10 of the heating plate 17, so that the distance between the material tray 12 and the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com