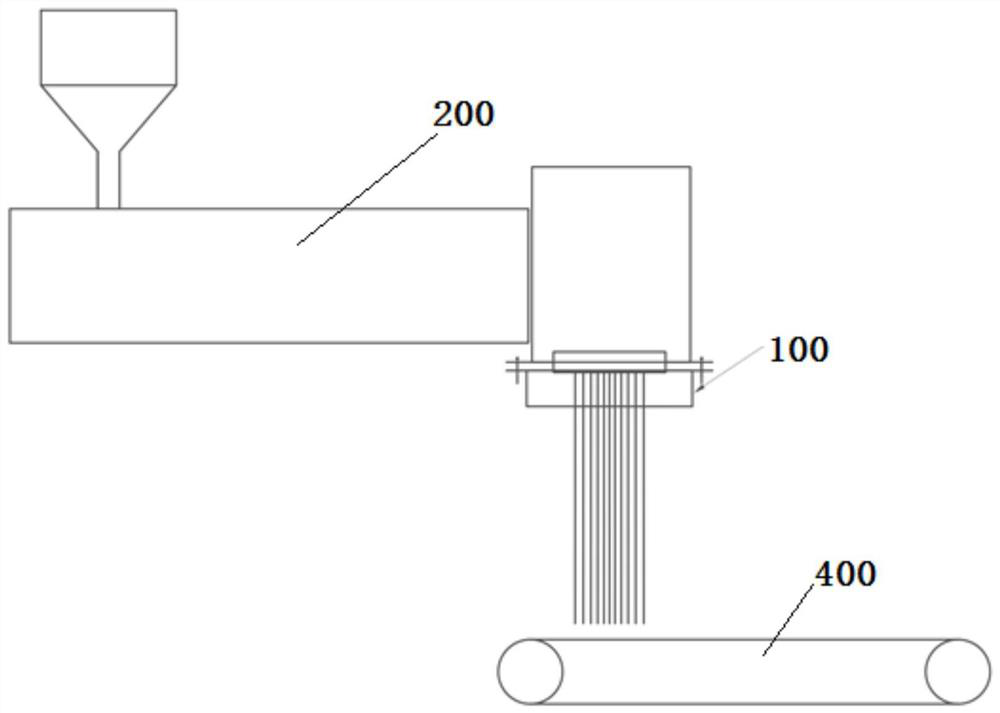

Multifunctional cooler, spinning equipment and preparation method of C-shaped oil absorption fibers

An oil-absorbing fiber and cooler technology, applied in the field of fiber manufacturing, can solve the problems that the shape of the fiber cannot be adjusted, and the effect of retaining the shape of the fiber is not good, and achieves excellent cooling effect, shape retention, and uniform air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

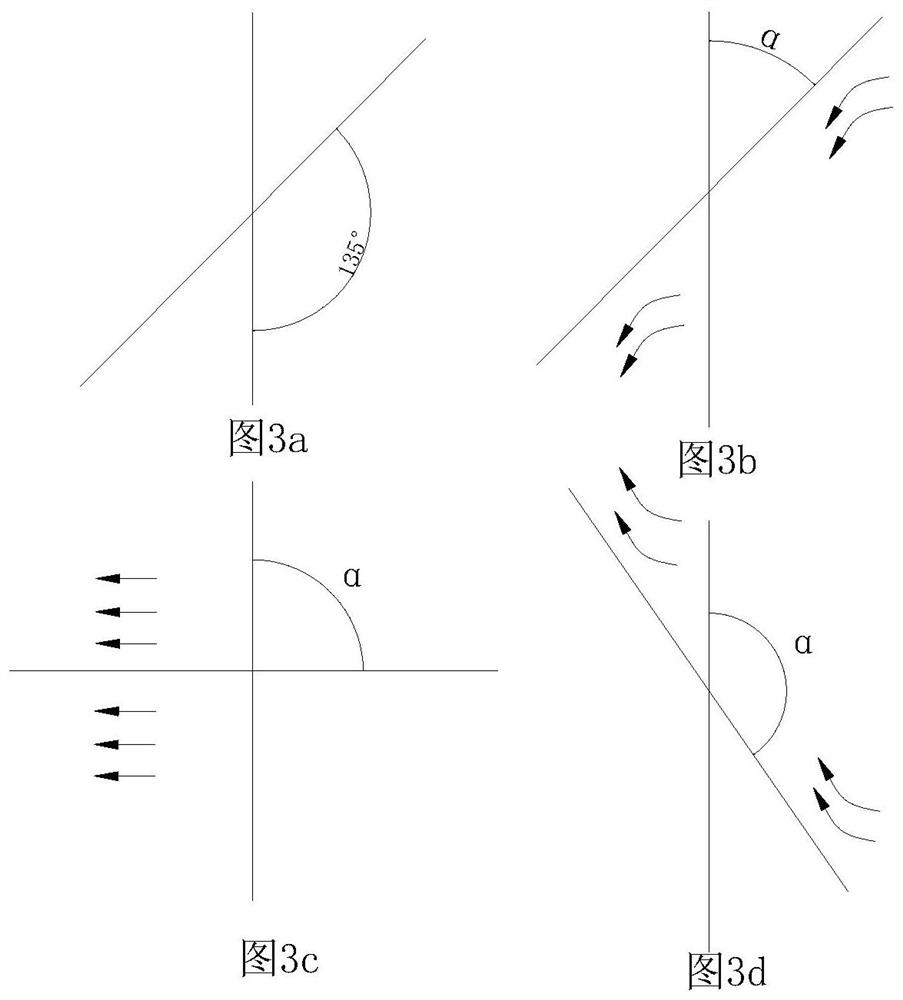

[0061] Example 4, 90° C-shaped oil-absorbing fibers with a large number of submicron pore structures were obtained by thermally induced phase separation on the basis of Example 2.

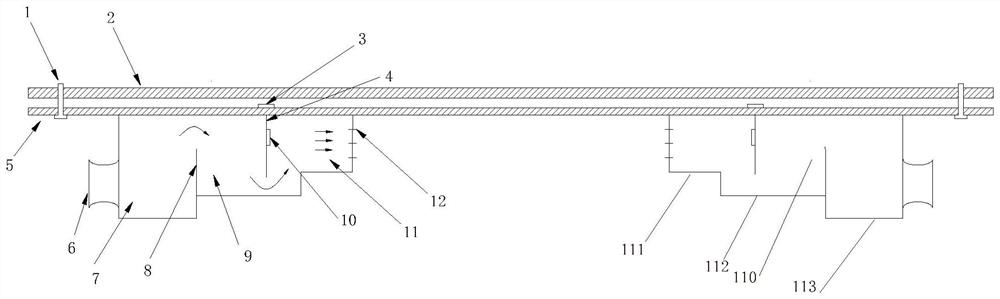

[0062] A method for preparing a C-shaped oil-absorbing fiber using a spinneret constructed of a multi-functional cooler according to the present invention, comprising the following steps:

[0063] Polypropylene pellets were melt mixed with dibutyl phthalate and dioctyl phthalate at 190°C. The homogeneous melt is then poured out and sliced after cooling. Add a non-woven fabric testing machine, and select a spinneret with a circular notch angle of 90° for spinning. The above-mentioned preferred multifunctional cooler adjusts the wind speed to 2m / s, the non-woven fabric testing machine has a suction of 2200r / min under the net, and the mesh belt machine is 1m / min, so that C-shaped fibers can be obtained. Soak the fiber with isopropanol and ethanol respectively, and replace the dibutyl phthalate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com