Acrylate rubber material, and preparation method and application thereof

A technology of acrylate and rubber materials, which is applied in the field of rubber, can solve the problems of materials being difficult to pass through, and achieve the effects of improved compression deformation, easy release of film, and reduced pressure change performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

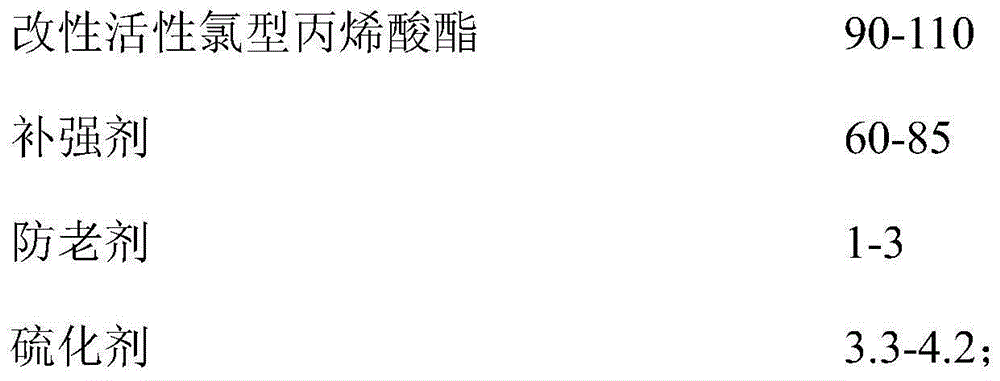

[0055] An acrylate rubber material is mainly prepared from the following raw materials in parts by weight:

[0056]

[0057]

[0058] (1) According to the formula, send all the raw materials into the internal mixer for two-stage mixing. The specific steps are as follows:

[0059] One stage: According to the formula, the modified active chlorinated acrylate, stearic acid, fast extruded carbon black, 4,4'-bis(α,α-dimethylbenzyl)diphenylamine, anti-scorch agent, mixed ether ester The type plasticizer and lubricant are sent into the internal mixer, mixed in the internal mixer for 5min, and deglue at 110-120°C;

[0060] The second stage: add sulfur, potassium stearate and sodium stearate to the masterbatch obtained in the first stage, banbury at low speed for 30-40s, then accelerate to the speed of the first stage for 40-60s, and then discharge at 90-100℃ Glue, get the mixed rubber;

[0061] The hardness, strength and elongation of the obtained mixed rubber were tested for ...

Embodiment 2

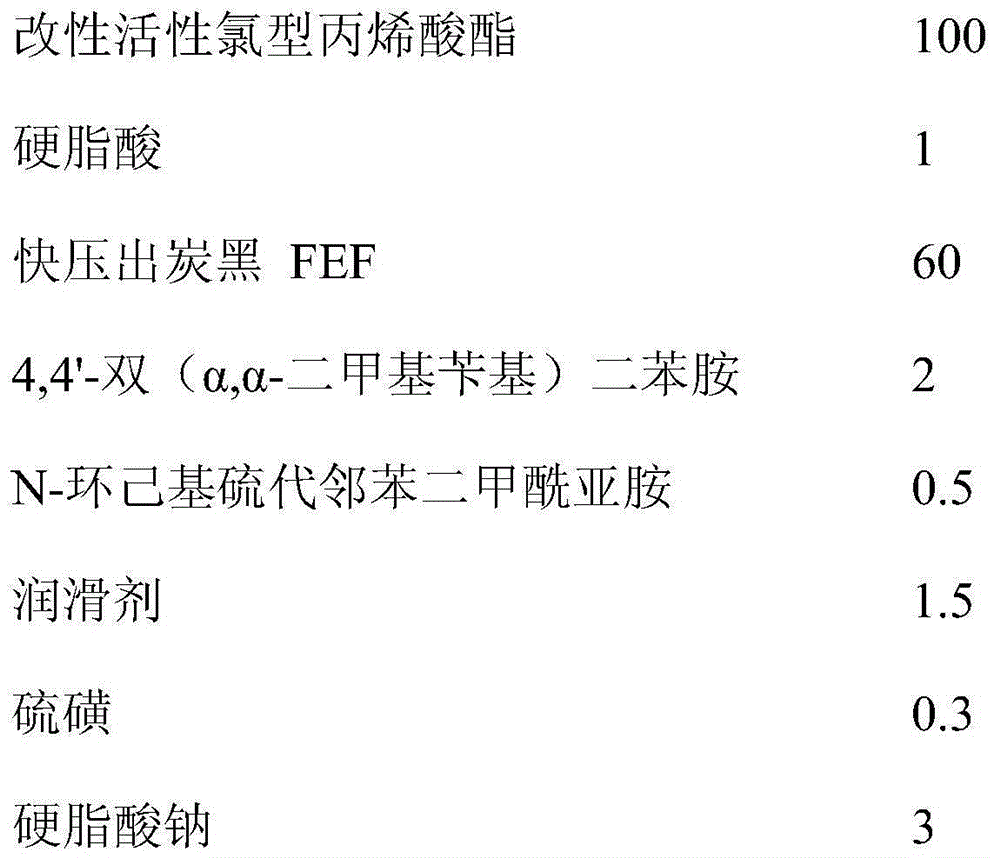

[0066] An acrylate rubber material is mainly prepared from the following raw materials in parts by weight:

[0067]

[0068]

[0069] (1) According to the formula, send all the raw materials into the internal mixer for two-stage mixing. The specific steps are as follows:

[0070] One stage: According to the formula, the modified active chlorinated acrylate, stearic acid, fast extruded carbon black, 4,4'-bis(α,α-dimethylbenzyl)diphenylamine, anti-scorch agent, mixed ether ester The type plasticizer and lubricant are sent into the internal mixer, mixed in the internal mixer for 5min, and deglue at 110-120°C;

[0071] The second stage: add sulfur, sodium stearate and potassium stearate to the masterbatch obtained in the first stage, banbury at low speed for 30-40s, then accelerate to the speed of the first stage for 40-60s, and then discharge at 90-100℃ Glue, get the mixed rubber;

[0072] The hardness, strength and elongation of the obtained mixed rubber were tested for ...

Embodiment 3

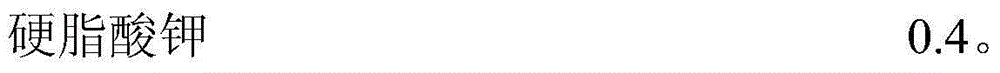

[0077] An acrylate rubber material is mainly prepared from the following raw materials in parts by weight:

[0078]

[0079]

[0080] (1) According to the formula, send all the raw materials into the internal mixer for two-stage mixing. The specific steps are as follows:

[0081] One stage: According to the formula, the modified active chlorinated acrylate, stearic acid, fast extruded carbon black, 4,4'-bis(α,α-dimethylbenzyl)diphenylamine, anti-scorch agent, mixed ether ester The type plasticizer and lubricant are sent into the internal mixer, mixed in the internal mixer for 5min, and deglue at 110-120°C;

[0082] The second stage: add sulfur, sodium stearate and potassium stearate to the masterbatch obtained in the first stage, banbury at low speed for 30-40s, then accelerate to the speed of the first stage for 40-60s, and then discharge at 90-100℃ Glue, get the mixed rubber;

[0083] The hardness, strength and elongation of the obtained mixed rubber are tested for h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com