Grease for plant-based candle and preparation method thereof

A plant-based and oil-based technology, applied in candles, fatty acid production, fatty acid esterification, etc., can solve the problems of brittle wax structure, oily palm wax surface, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

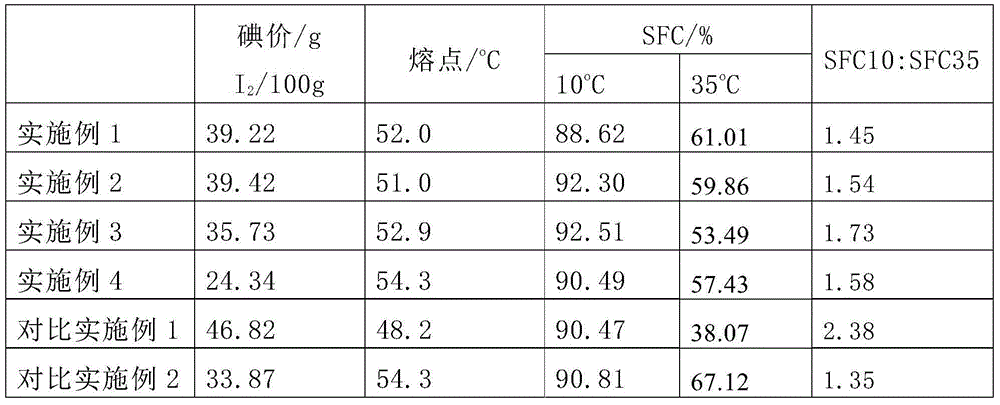

Embodiment 1

[0070] Preparation of fats and oils: using the above method to prepare 52°C hydrogenated rice bran fat products, and subjecting the hydrogenated rice bran fats to the above-mentioned transesterification preparation conditions to obtain oil products.

[0071] Preparation of the candle: melt the hydrogenated rice bran lipid transesterification product at 75° C., add purple dye, pour it into a mold, let it cool at room temperature, and finally remove the mold to obtain a pillar wax.

Embodiment 2

[0073] Preparation of oil: melt the hydrogenated soybean oil product with a melting point of 50°C and the hydrogenated rice bran fat product with a melting point of 52°C at a ratio of 1:9, and obtain the oil product according to the above-mentioned transesterification preparation process.

[0074] Preparation of the candle: Melt the transesterified product at 75°C, add dye, pour it into a mold, let it cool at room temperature, and finally remove the mold to obtain a pillar wax.

Embodiment 3

[0076] Preparation of oil: melt the hydrogenated soybean oil product with a melting point of 44°C and the hydrogenated rice bran fat product with a melting point of 58°C at a ratio of 1:1, and obtain the transesterified product according to the above transesterification preparation process.

[0077] Preparation of the candle: Melt the transesterified product at 75°C, add dye, pour it into a mold, let it cool at room temperature, and finally remove the mold to obtain a pillar wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com