Oil quantity detection and alarm mechanism of industrial sewing machine

An industrial sewing machine and oil quantity technology, which is applied to sewing machine components, sewing equipment, textiles and paper making, etc., can solve the problems of inaccurate oil quantity indication, easy oil leakage or misidentification of stuck oil marks, etc. Easy to get stuck and error, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

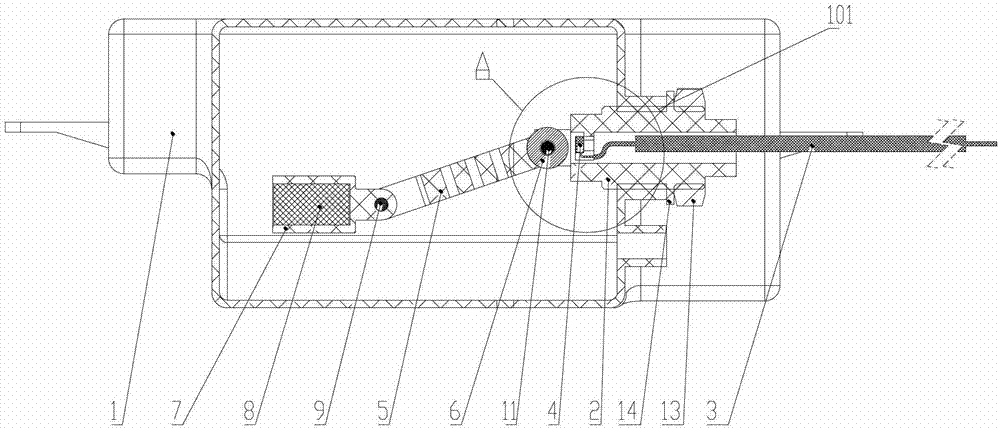

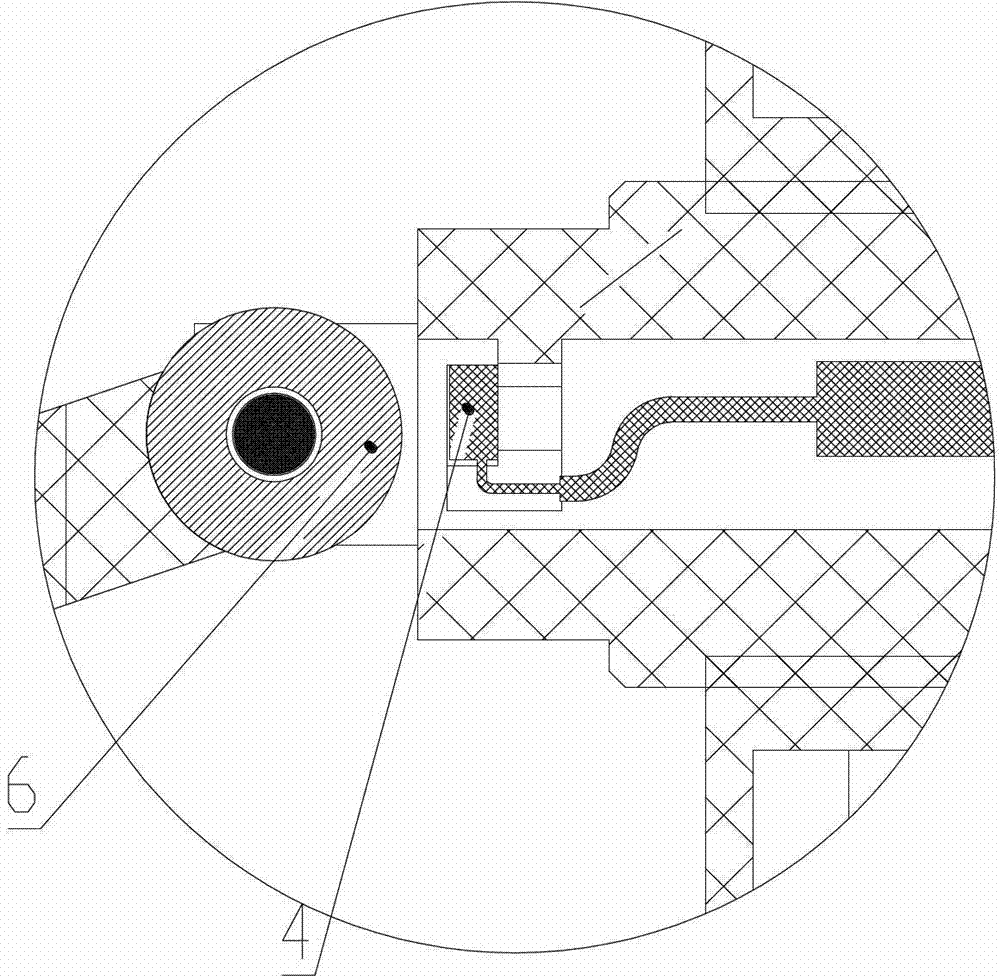

[0022] as attached figure 1 and 2 As shown, an oil quantity detection and alarm mechanism for an industrial sewing machine includes a rotary hook oil supply box 1, and a mounting hole 101 is opened on the side wall of the rotary hook oil supply box 1, and a mounting hole 101 is fixed inside the mounting hole 101. Oil quantity detection frame 2, the inner cavity of oil quantity detection frame 2 is equipped with wire 3, one end of wire 3 protrudes outside rotary hook oil supply box 1, the other end is connected with Hall 4, and Hall 4 is fixed on oil quantity detection frame 2 One end close to the inner cavity of the rotary hook oil supply box 1 on the top, and the other end close to the inner cavity of the rotary hook oil supply box 1 on the oil quantity detection frame 2 is movably connected with a connecting rod 5, and a magnet 6 is installed at the joint, and the magnet 6 is connected to the Hall 4 corresponds, the other end of connecting rod 5 is movably connected with fl...

Embodiment 2

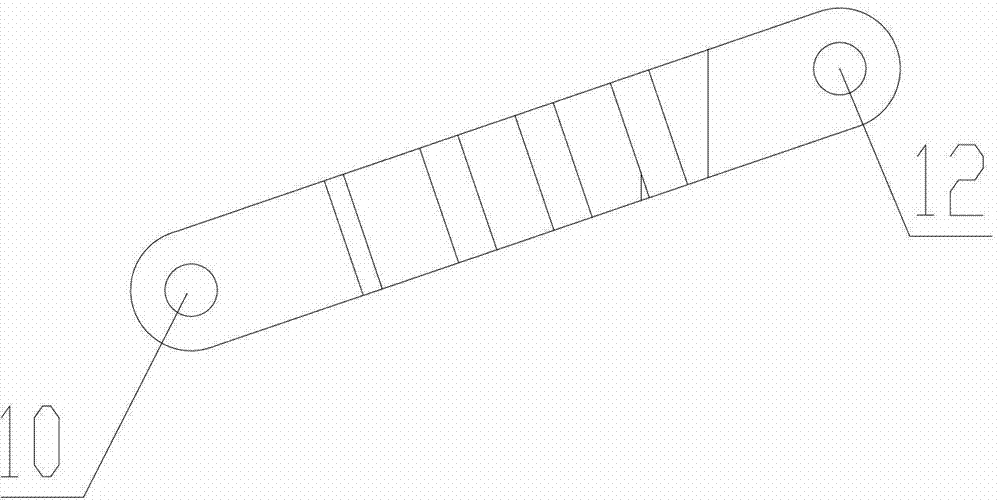

[0034] as attached image 3 As shown, the buoy 7 is connected with the connecting rod 5 through the first connecting rod protruding shaft 10 .

[0035] The connecting rod 5 is installed on the pin shaft hole of the oil quantity detection frame 2 through the second connecting rod protruding pin 12, and the magnet 6 is sleeved on the second connecting rod protruding pin 12, and the magnet 6 is circular.

[0036] The present invention uses a combination of machinery and electricity to display the oil quantity indication of industrial sewing machine lubricating oil. The whole mechanism does not need to be connected to the outside by pipelines, has good sealing performance, can accurately display the oil quantity, has simple structure, and is convenient to manufacture, avoiding the troublesome mechanical methods in the past. Stuck and error conditions ensure that the industrial sewing machine will not leak oil during transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com