Thin oil lubricating device

A technology of thin oil lubrication and lubricating pump, applied in the direction of engine lubrication, presses, engine components, etc., can solve problems such as oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The thin oil lubricating device of the present invention will be further described below with reference to the accompanying drawings and examples.

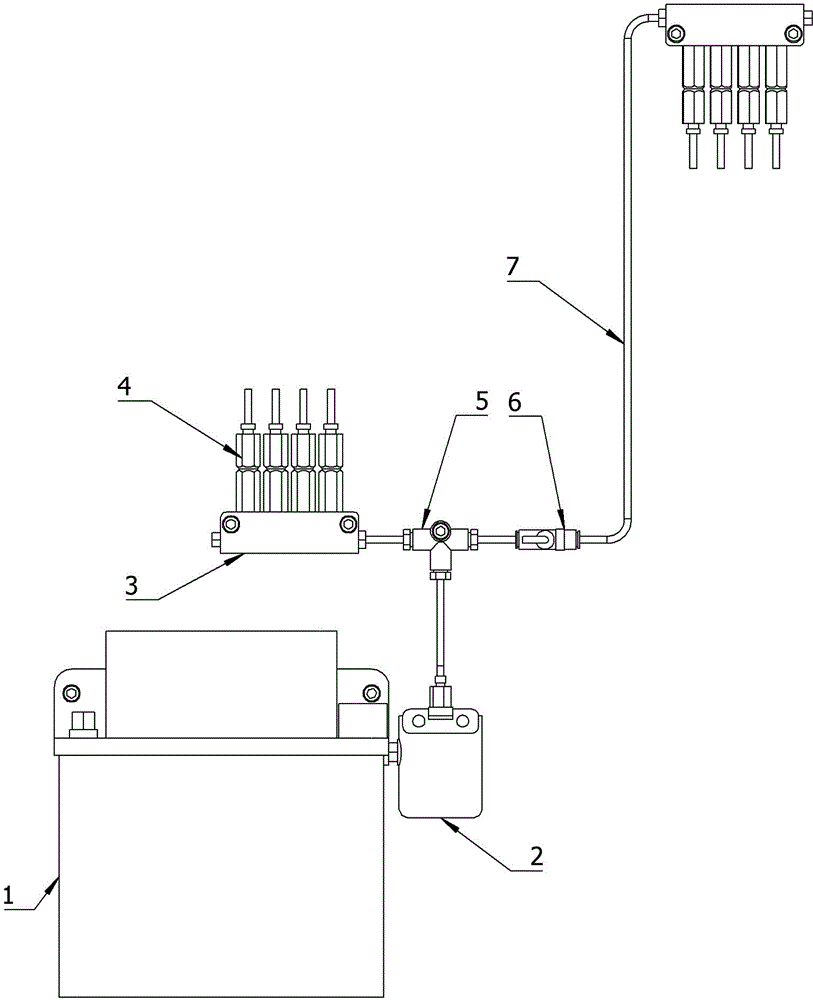

[0007] Such as figure 1 As shown, the thin oil lubricating device of the present invention includes an electric lubricating pump 1, an oil filter 2, a multi-way oil separation block 3, a quantitative oil injector 4, a three-way joint 5, a one-way throttle valve 6 and an oil pipe 7, wherein the filter After the oiler 2 is installed on the electric lubricating pump 1, it is connected with the three-way joint 5 through the oil pipe 7, and the three-way joint is divided into two roads to connect with the multi-way oil distribution block 3 respectively, and one-way throttle valve 6 is installed in one oil road , Quantitative lubricator 4 is respectively installed on the multi-pass oil distribution block 3 and then connected to each lubricating point through the oil pipe, and the lubricating period, lubricating time and lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com