Multi-functional built-in dynamic-static-pressure motorized spindle for efficient high-speed precision machine

A dynamic and static piezoelectric, built-in technology, which is applied in the field of machine tools, can solve the problems that the thrust bearing oil chamber pressure cannot be maintained well, the coolant and oil seal cannot be guaranteed, and the performance of the end thrust bearing is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

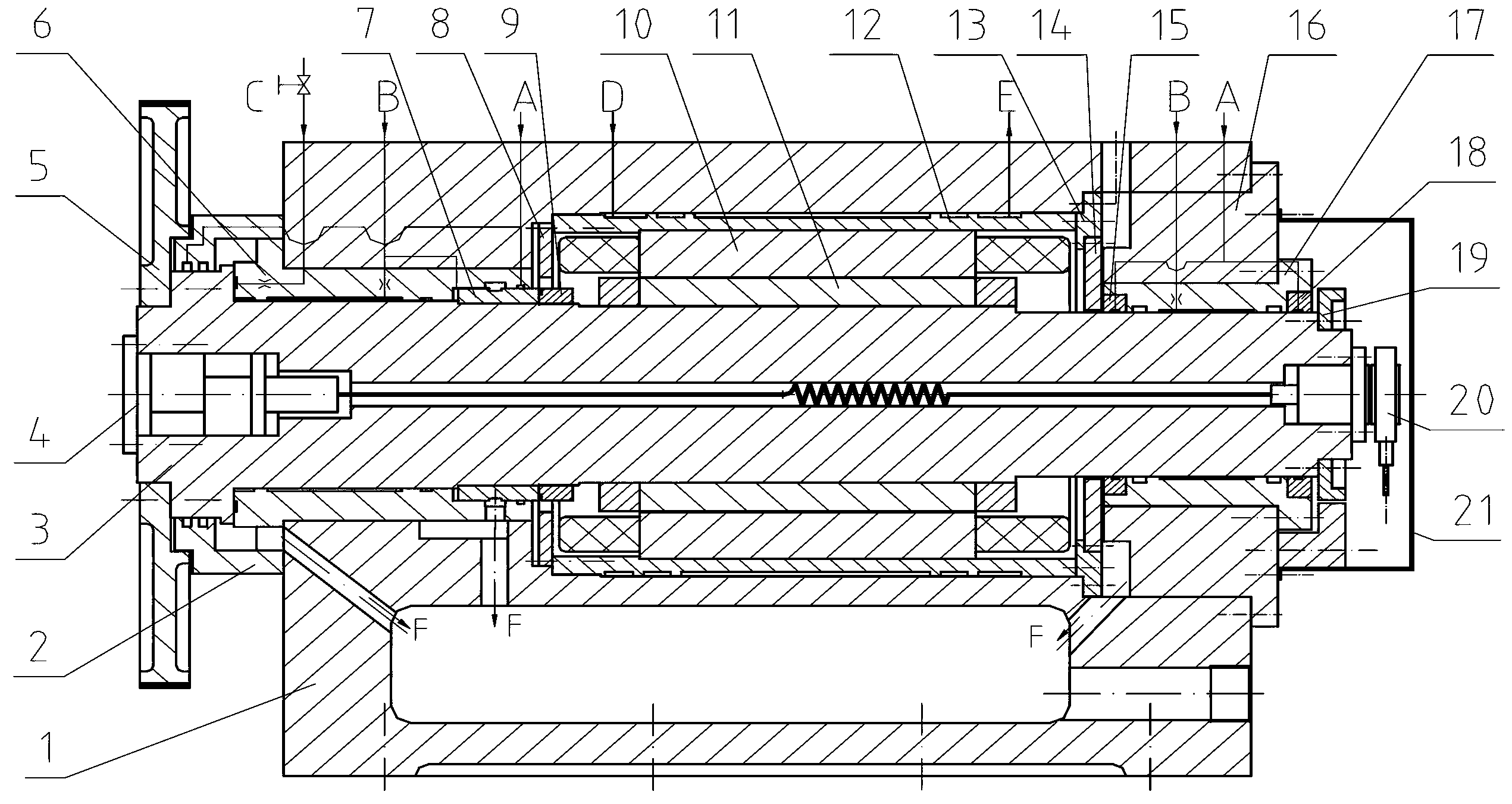

[0029] Such as figure 1 As shown, a dynamic and static piezoelectric spindle with a built-in multifunctional motor consists of a box body 1, an oil seal cover 2, a spindle 3, a balance head 4, a grinding wheel 5, a front bearing 6, a preloaded piston 7, a front heat shield ring 8, Lock nut 9, motor stator 10, motor rotor 11, water jacket 12, stator fixing ring 13, rear heat shield ring 14, first air seal ring 15, rear bearing seat 16, rear bearing 17, second air seal ring 18 , Rotary encoder 19, dynamic balance receiver 20, shield 21, air supply channel A, channel B for supplying pressure oil to the radial bearing and piston cavity, channel C for controllable pressure oil of the front end thrust bearing, motor stator water jacket cooling It is composed of water inlet D, motor stator water jacket cooling water outlet E and lubricating oil return channel F.

[0030] Said front bearing 6 is installed on casing 1 front end with screw by front end flange, and described rear bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com