Preparation method of instant pickled beef

A dry and beefy technology, which is applied in the field of food manufacturing, can solve the problems of high hardness and tough taste, and achieve the effects of moderate toughness and crispness, good sliceability and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

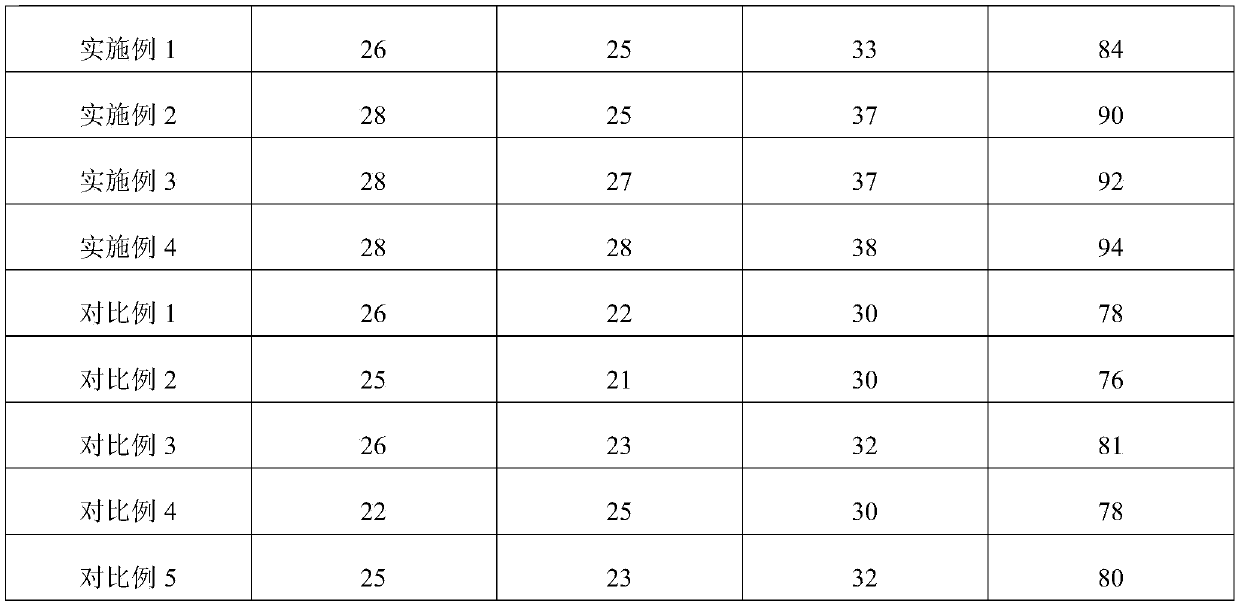

Embodiment 1

[0032] A preparation method of instant dried beef, comprising the following steps,

[0033] S1. Pretreatment: Select the beef, remove the fascia on the surface, clean it, then cut it into slices along the texture of the beef, with a thickness of 8-15 mm, and finally dry the surface moisture to obtain beef slices.

[0034] S2. Tenderizing and marinating: add compound enzymes to the beef slices and mix evenly, tenderize at room temperature for 30 minutes, then add compound phosphates accounting for 0.1% by mass of the beef slices, stir evenly, place at room temperature for 30 minutes, and finally Add pickling preparations for tumbling, and use a tumbling machine to tumbling evenly; tumbling conditions: forward rotation for 15 minutes, intermittent for 10 minutes, reverse rotation for 15 minutes, intermittent for 10 minutes, vacuum degree -0.07MPa, to obtain raw meal for use.

[0035] The compound enzyme includes: 80 U / g of trypsin, 80 U / g of papain and 50 U / g of transglutaminase...

Embodiment 2

[0044] A preparation method of instant beef jerky, compared with Example 1, step S1. Pretreatment is different, other steps are the same.

[0045] S1. Pretreatment: Select the beef, remove the fascia on the surface, clean it, then cut it into slices along the texture of the beef, with a thickness of 10mm, and finally dry the surface moisture to obtain beef slices.

[0046] Remove the superficial fascia of the beef, then soak it with 0.1% citric acid water for 25 minutes, remove the blood, soak it with 0.1% sodium bicarbonate aqueous solution for 25 minutes, remove the blood impurities again, and then wash it.

Embodiment 3

[0048] A preparation method of instant beef jerky, compared with Example 1, step S1. Pretreatment is different, other steps are the same.

[0049] S1. Pretreatment: Select the beef, remove the fascia on the surface, clean it, then cut it into slices along the texture of the beef, with a thickness of 10mm, and finally dry the surface moisture to obtain beef slices.

[0050] Remove the superficial fascia of the beef, then soak it with 0.1% citric acid water for 25 minutes, remove the blood, soak it with 0.1% sodium bicarbonate aqueous solution for 25 minutes, remove the blood impurities again, and then wash it.

[0051] After cleaning the beef, soak it in boiling water for 5 minutes, remove it, soak it in ice cube water for 10 minutes, repeat the operation twice, then drain and cut into slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com