Method for preparing biodegradable oil absorption material

An oil-absorbing material and biodegradation technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult degradation of oil-absorbing materials, slow oil-absorbing speed, and high cost of raw materials, and achieve good biodegradability, fast and efficient oil absorption, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] After mixing 160 grams of bagasse fiber and 40 grams of tapioca starch evenly, add it into a reaction vessel with a capacity of 1 liter, then add 60 grams of sodium hydroxide solution with a mass concentration of 10%, stir evenly, and then add 20 grams of butyl acrylate The ester monomer and 1 gram of potassium persulfate were stirred evenly, placed in a microwave reactor with a working frequency of 80KHz and a power of 1000W, heated to 60°C and reacted for 50 minutes to obtain 223 grams of the oil-absorbing material of the present invention.

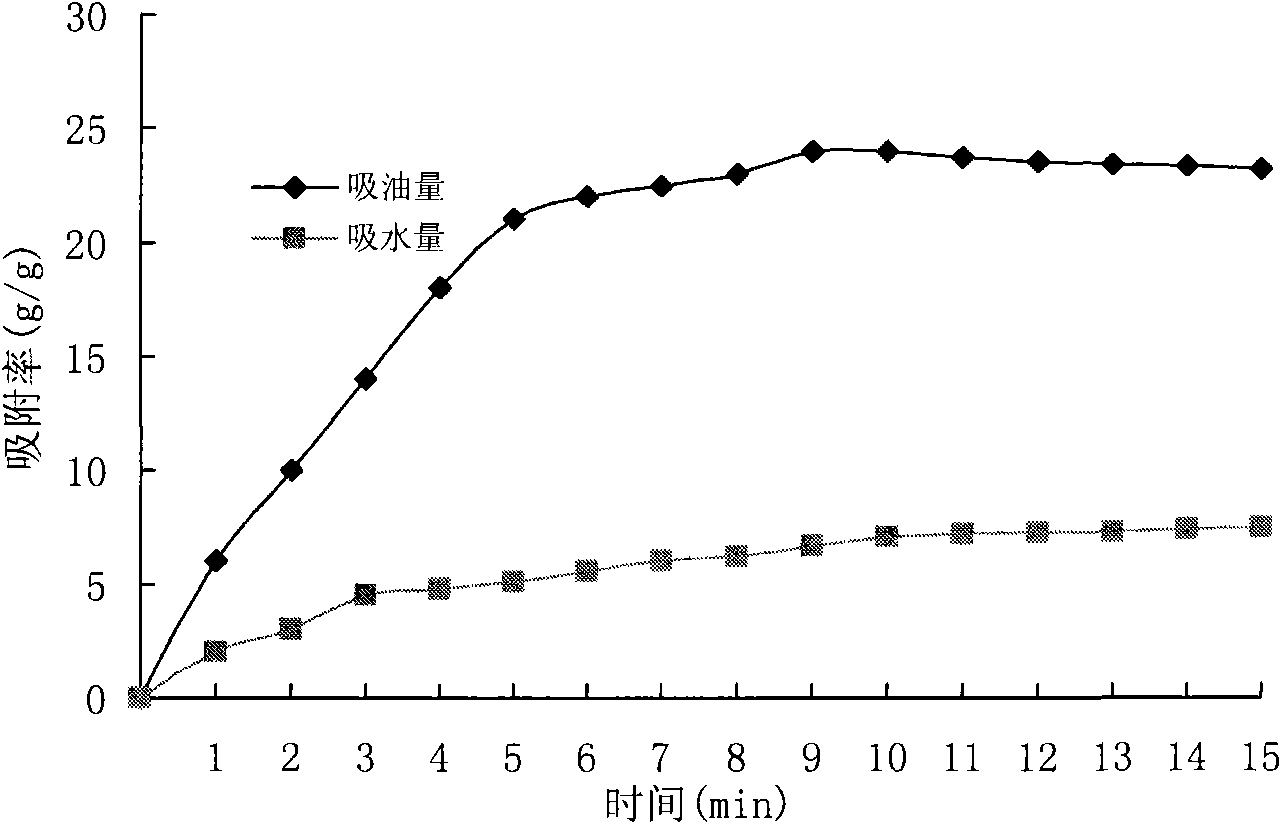

[0056] The applicant has carried out application experiment with above-mentioned oil-absorbing material, and its result sees figure 1 . from figure 1 It can be seen that the oil-absorbing material exhibited rapid adsorption capacity in the first 5 minutes of the test, and the speed decreased significantly after reaching a certain degree of saturation. Therefore, the test shows that the fast adsorption performance of this materi...

Embodiment 2

[0058] After mixing 100 grams of cassava stalk fiber and 100 grams of potato starch evenly, add it into a reaction vessel with a capacity of 1 liter, then add 40 grams of sodium hydroxide solution with a mass concentration of 80%, stir evenly, and then add 30 grams of Heptyl acrylate monomer and 2 grams of ammonium persulfate, after stirring evenly, heated up to 60°C under microwave reaction conditions of 80KHz working frequency and 1200W power, and reacted for 30 minutes to obtain 231 grams of the oil-absorbing material of the present invention .

Embodiment 3

[0060] After mixing 110 grams of cornstarch and 90 grams of cotton stalk fibers evenly, add them to a reaction vessel with a capacity of 1 liter, then add 200 grams of sodium hydroxide solution with a mass concentration of 30%, stir well, and then add 60 grams of methyl Cetyl acrylate monomer and 0.5 g of ceric sulfate, after stirring evenly, under the microwave reaction conditions of working frequency of 120KHz and power of 2000W, heated up to 50°C and reacted for 60 minutes to obtain the oil-absorbing material 265 of the present invention gram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com