Static-pressure gas bearing

A technology of floating bearings and bearings, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as rubbing and vibration, solid locking, and rotors that cannot be balanced and floated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

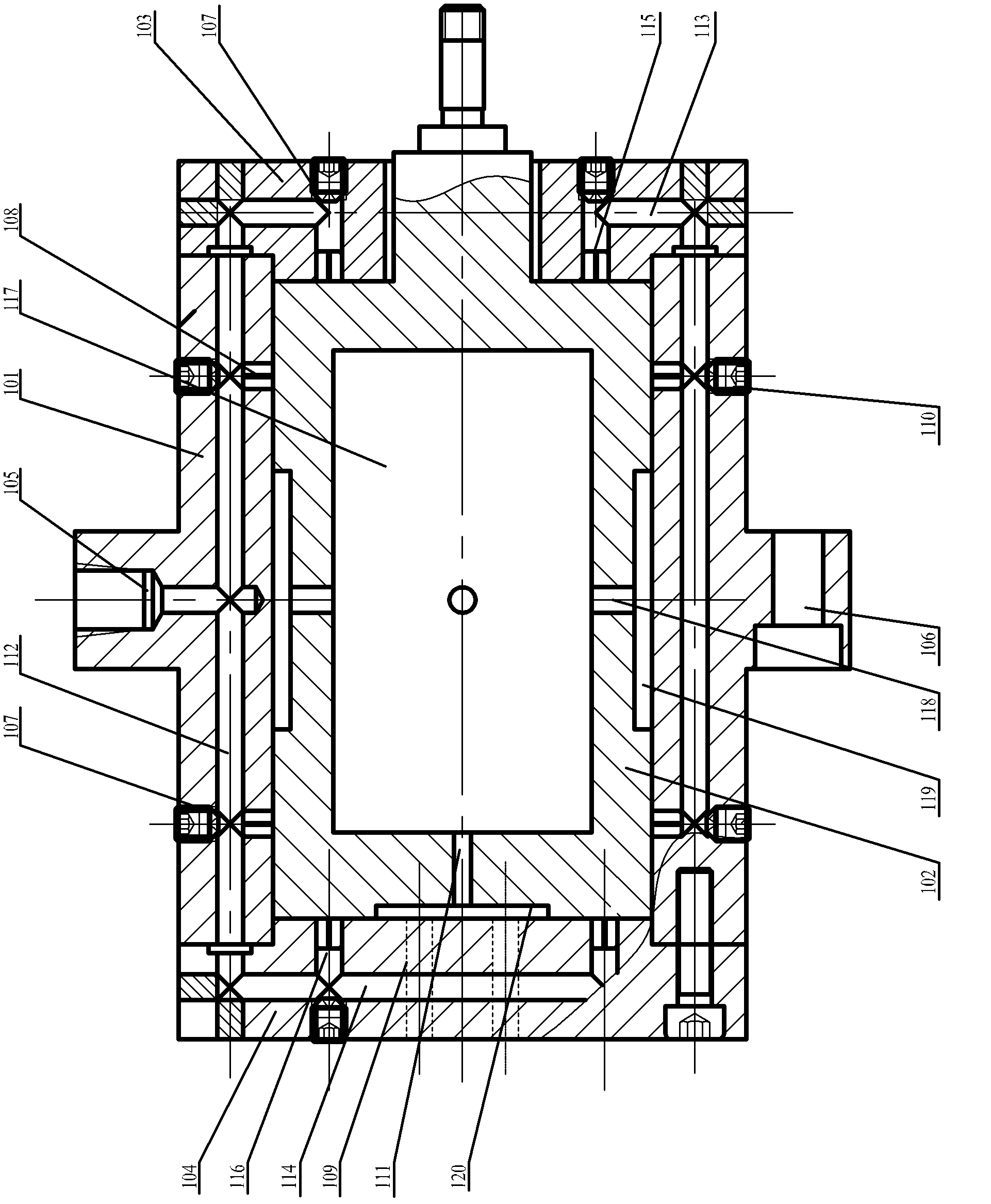

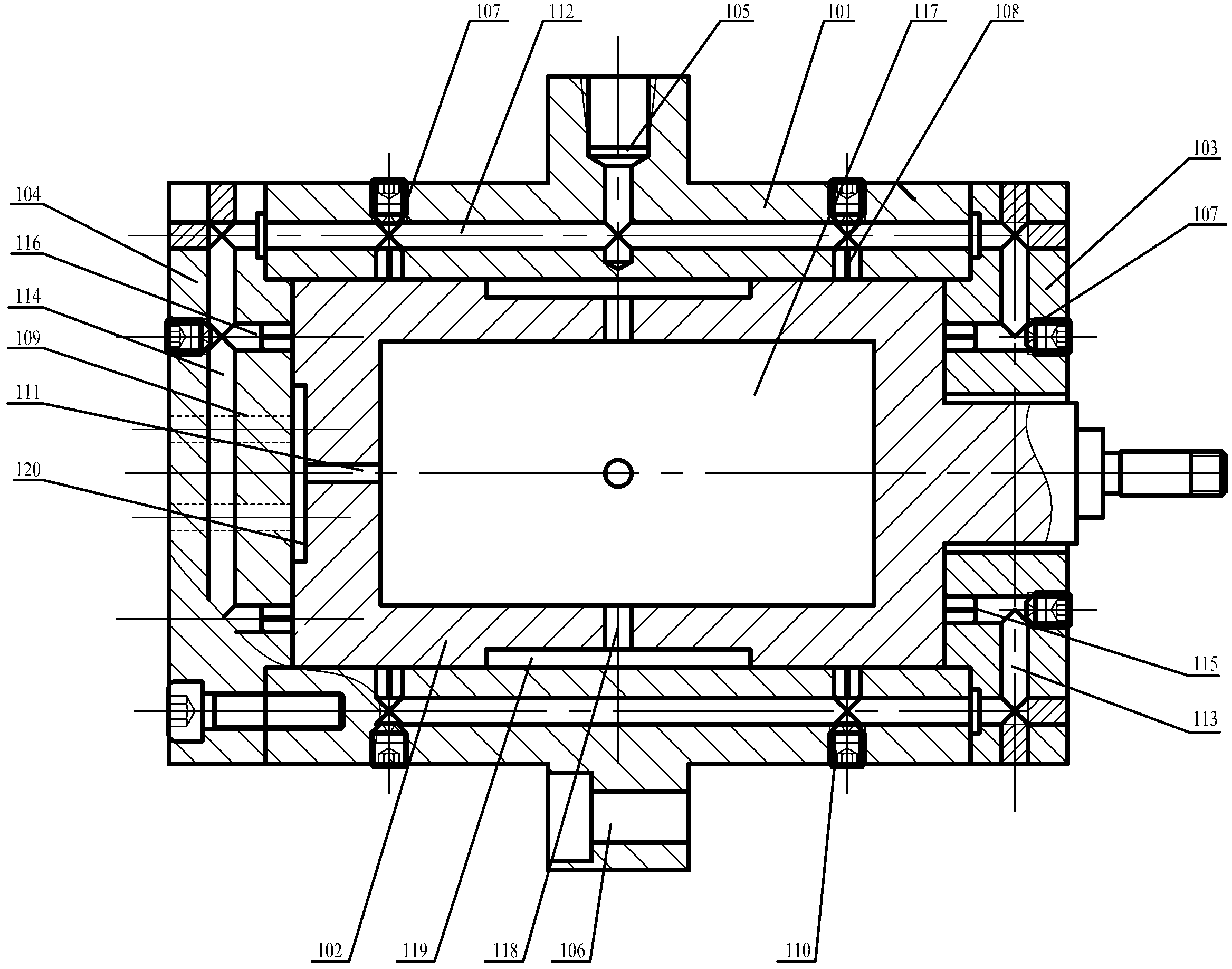

[0016] As shown in the figure, the present invention mainly consists of a bearing main body 101, a rotor 102, a front cover 103, a rear cover 104, an air inlet 105, a fixing hole 106, a threaded hole 107, a main body jet hole 108, an air outlet 109, a screw 110, a shaft Air outlet hole 111, main body air chamber 112, front cover air chamber 113, rear cover air chamber 114, front cover air injection hole 115, rear cover air injection hole 116, rotor air chamber 117, radial air outlet hole 118, circular groove 119 and Circular concave groove 120 and other components constitute.

[0017] The static pressure air bearing includes a cylindrical bearing main body 101, a rotor 102 is installed in rotation in the bearing main body 101, a front cover 103 is fixed on the right shaft end of the bearing main body 101, and a left side shaft end of the bearing main body 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com