Wire releasing device with replaceable outer sleeve

A technology of pay-off device and jacket is applied in the field of optical fiber pay-off device with replaceable jacket, which can solve the problems of affecting the wiring environment, not being able to shock the reel, and the use environment being harsh, so as to improve the wiring environment, improve the vibration problem, reduce the good shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

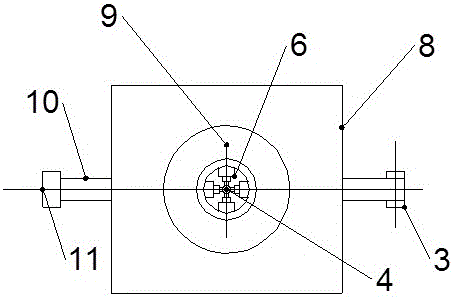

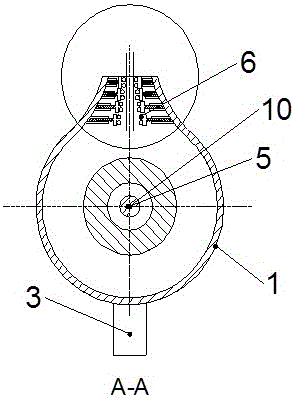

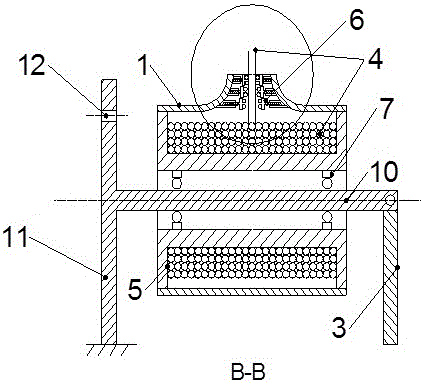

[0045] Figure 1-Figure 7 Be the optical fiber pay-off device of the replaceable jacket of the present invention, as Figure 1-7 As shown, the optical fiber pay-off device with a replaceable jacket of the present invention includes a replaceable jacket 1, a fixed bracket 2, a movable bracket 3, a reel 5 and a guide device 6, and the replaceable jacket 1 is sleeved outside the reel 5, and the connection can be Realized by conventional structures such as threaded connection structure, general buckle structure or nylon structure, the optical fiber 4 is wound up on the reel 5, and one end is fixed on the reel 5, and the other end is arranged outside the pay-off device after passing through the guide device 6, The fixed bracket 2 includes a vertically arranged fixed beam 11 and a horizontally arranged support bar 10. The bottom of the fixed beam 11 is fixed, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com