Automatized material conveying system and its storage cabinet

A technology for handling systems and storage cabinets, applied in the field of automated storage systems, can solve problems such as reducing machine setup rate and occupying area, and achieve the effects of simplifying design, saving space utilization, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

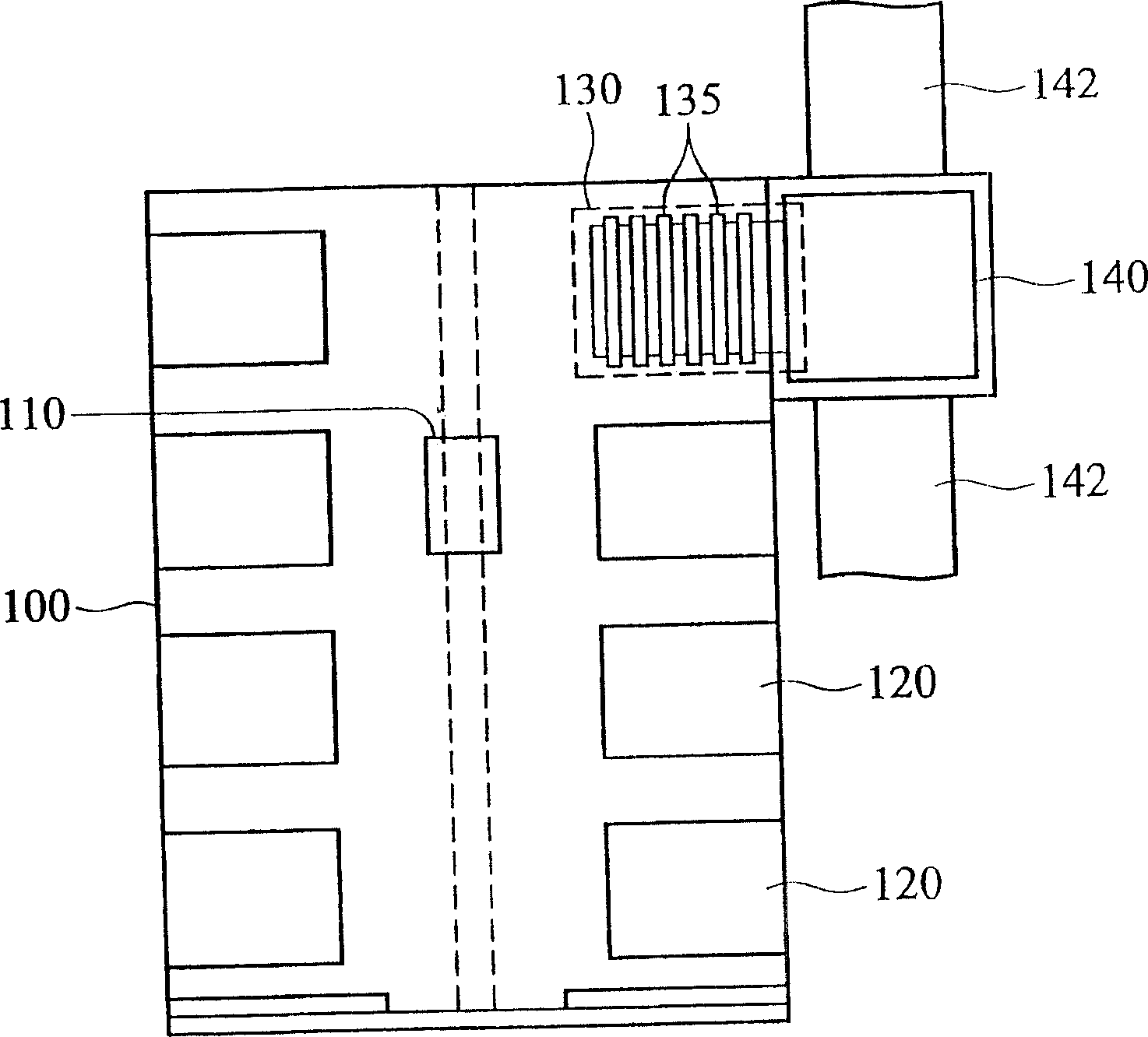

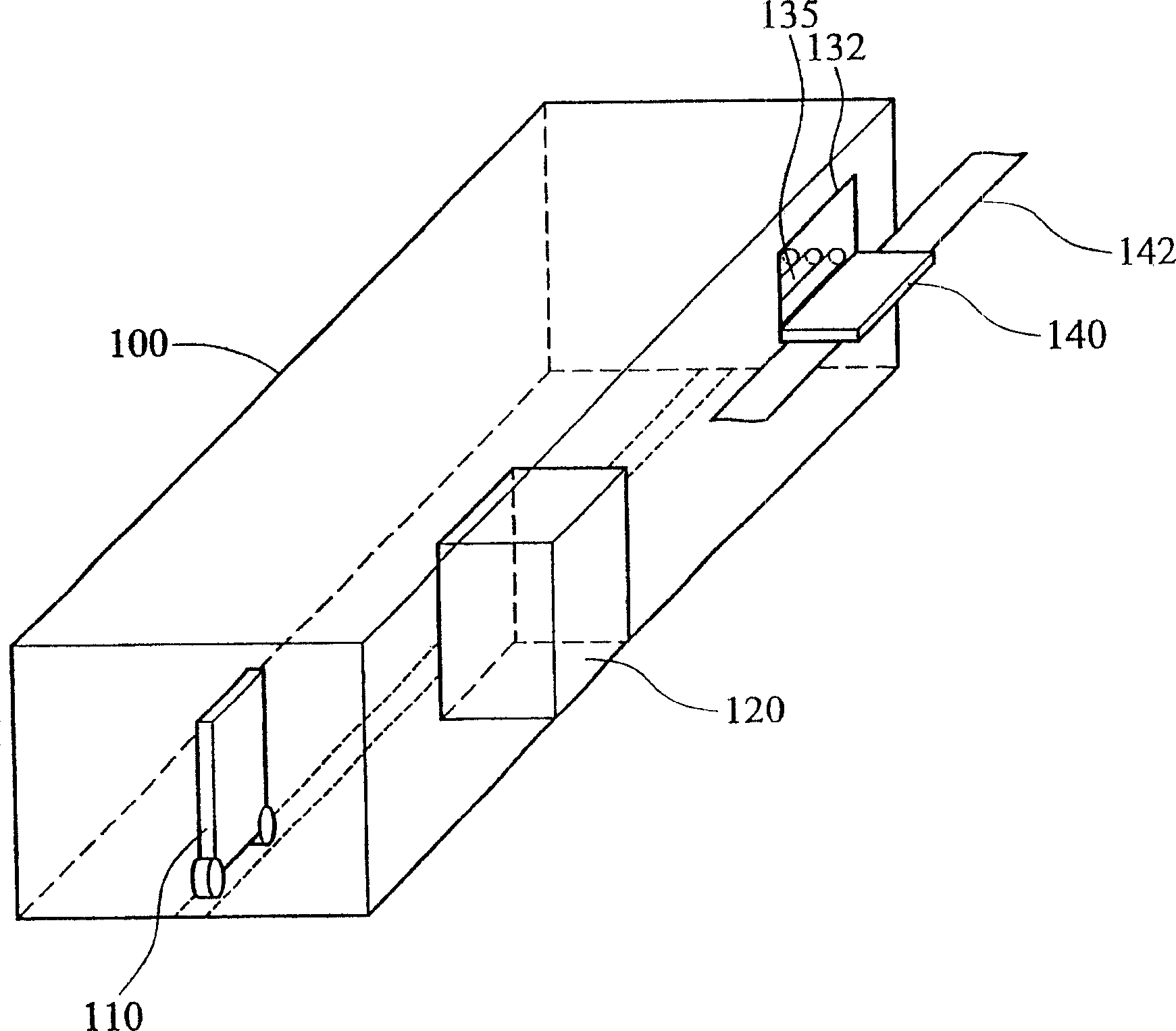

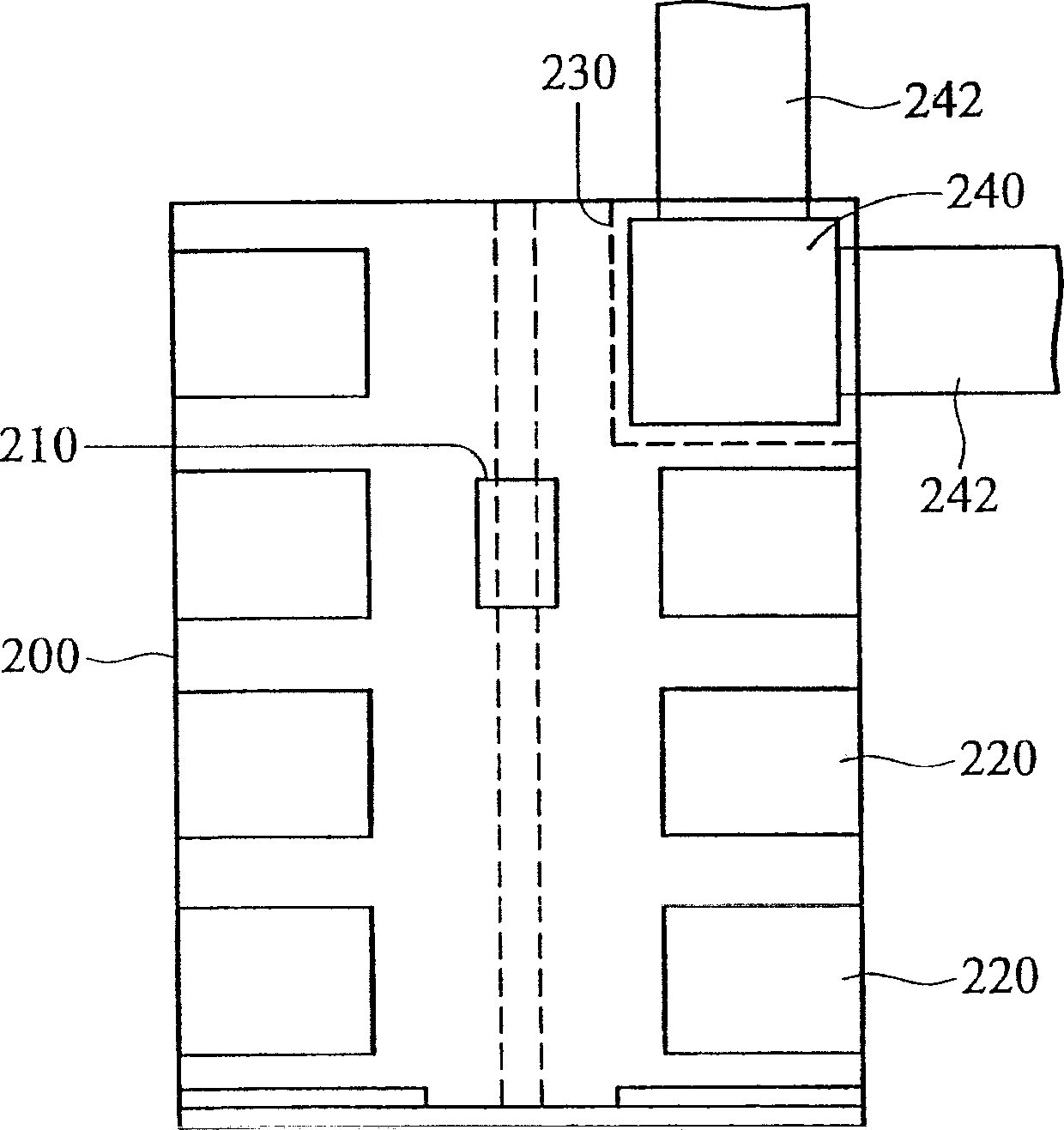

[0011] The first embodiment of the automated material handling system of the present invention is as Figure 2a As shown, it includes a conveying track (crane track) 242 , a conveying vehicle (cradle) 240 and a storage cabinet 200 . The transport vehicle 240 can move on the transport track 242 . The storage cabinet 200 includes a pick-and-place part 230 , and the pick-and-place part 230 is located in the storage cabinet 200 . Wherein, the conveying track 242 extends into the storage cabinet 200 and overlaps with the pick-and-place part 230. When the conveying vehicle 240 is located at the pick-and-place part 230, the transfer machine 210 directly puts materials into the conveying vehicle 240 middle.

[0012] When materials are to be moved from the storage cabinet 200 to the crane 240, the transfer machine 210 first takes the materials out of the storage compartment 220, and then transports them to the pick-and-place unit 230, and directly places the materials on the crane 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com