Flexible sealing main shaft center cooling device

A flexible sealing and cooling device technology, applied in the field of mechanical processing, can solve the problems of reducing labor intensity and not being able to better adapt to workpiece length tolerances, and achieve the effects of reducing labor intensity, improving clamping and positioning efficiency, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

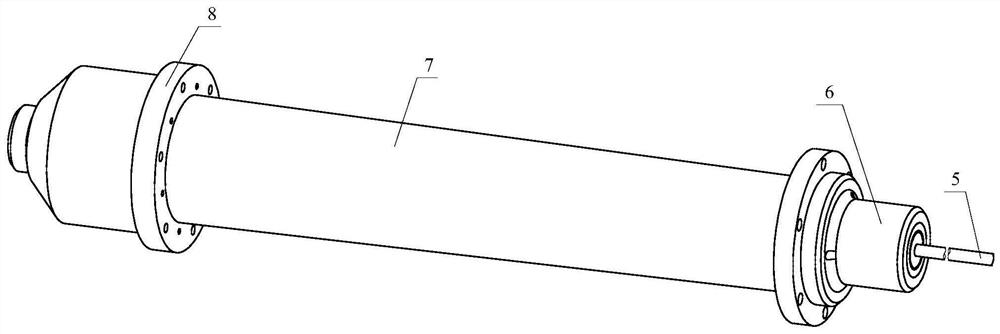

[0035] Such as figure 1 As shown, a flexible sealed spindle center cooling device of the present invention is installed at the end of the machine tool spindle for positioning and clamping the workpiece 5 .

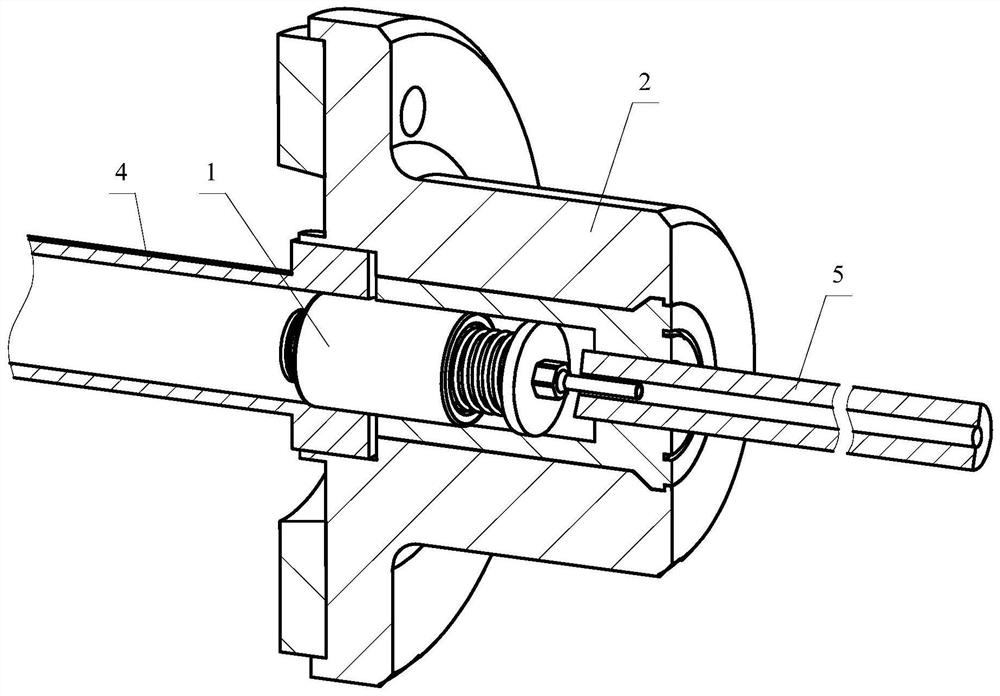

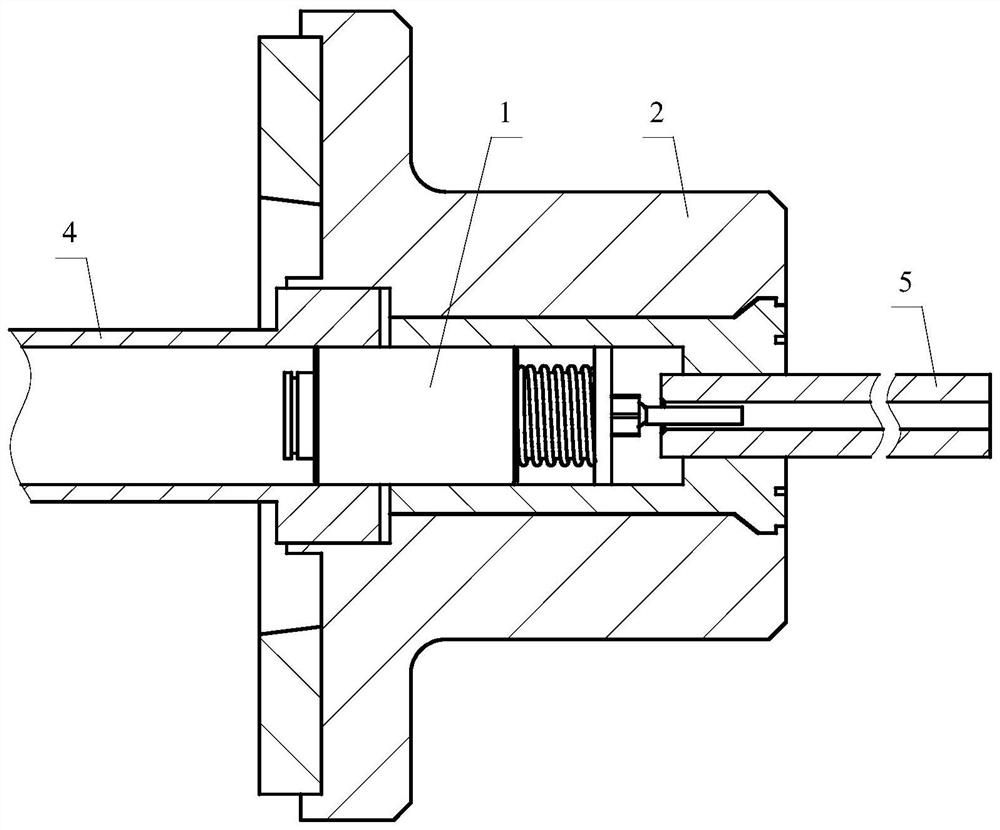

[0036] Such as Figure 2-3 As shown, a flexible sealing spindle center cooling device includes a flexible sealing part 1 and a clamping part 2 sleeved on the outer wall of the flexible sealing part 1. The flexible sealing part 1 is used to seal the inner hole entrance of the workpiece 5 and compensate the axis of the workpiece 5 Tolerance, the clamping part 2 is used to clamp the workpiece 5.

[0037] Such as Figure 4-5 As shown, the flexible sealing part 1 includes an outer sleeve 11 and an inner sliding sleeve 12 that are mutually fitted and can slide relative to each other. The outer sleeve 11 is fixedly connected with the clamping part 2, and a Elastic element 13, to realize the axial reset movement of inner sliding sleeve 12;

[0038] Wherein, the outer sleeve 11...

Embodiment 2

[0053] A lathe, comprising a pedestal, the pedestal is provided with a flexible sealing main shaft central cooling device.

[0054] The present invention possesses stronger versatility, with reference to figure 1 , assembled in the chuck structure of the lathe; the lathe is equipped with the flexible sealing spindle center cooling device of the present invention, which is used to process and manufacture pipes, so as to improve the clamping and positioning efficiency of workpieces, compensate the length tolerance of pipes and buffer axial vibration impact , improve the service life of the tool; especially for precision pipes with a large length-to-diameter ratio, it can significantly reduce labor intensity, improve processing efficiency and tool life, and is conducive to the development of basic manufacturing processes.

[0055] All features disclosed above, or steps in all methods or processes disclosed above, may be combined in any manner, except for mutually exclusive featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com