Processing method of parts with long shaft and thin wall and processing clamp thereof

A kind of parts and thin-walled technology, which is applied in the field of mechanical processing of long-axis thin-walled parts, can solve the problems of long-axis thin-walled parts that are prone to deformation, low processing pass rate, and failure to meet technical parameter requirements, so as to prevent Forced deformation, reducing the difficulty of clamping and processing, and avoiding the effect of part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

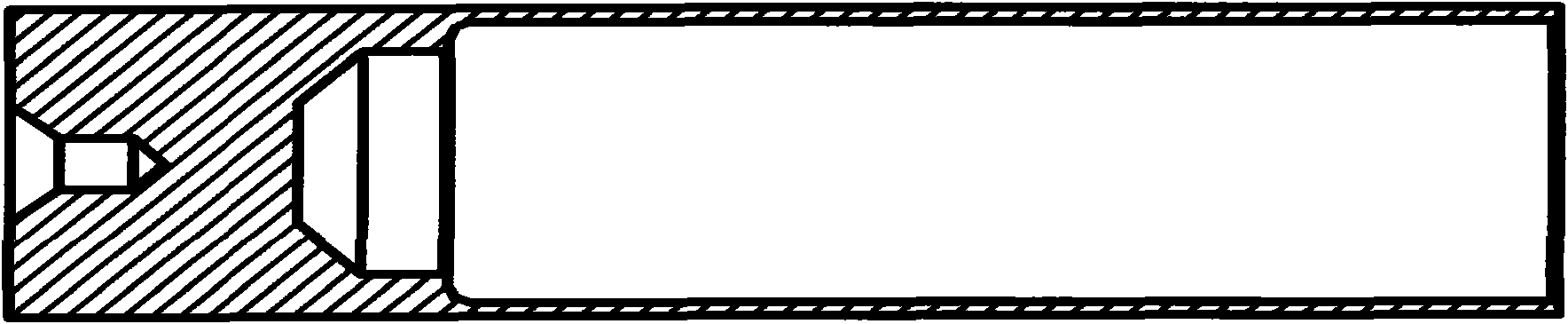

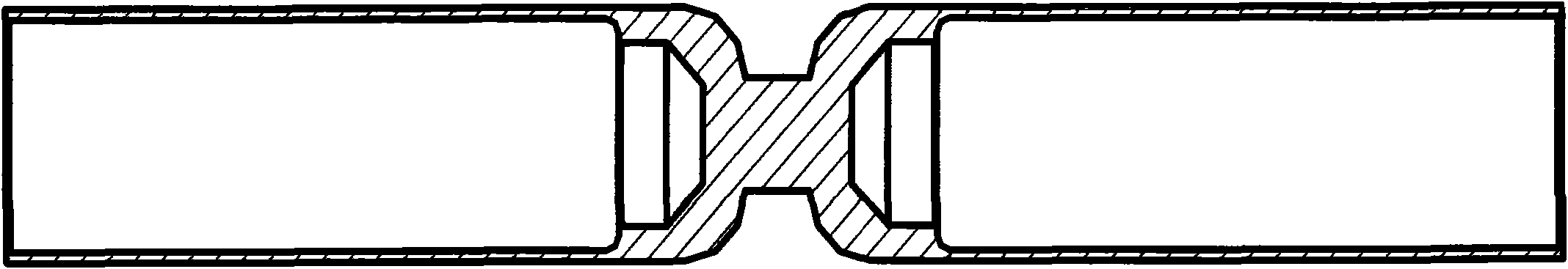

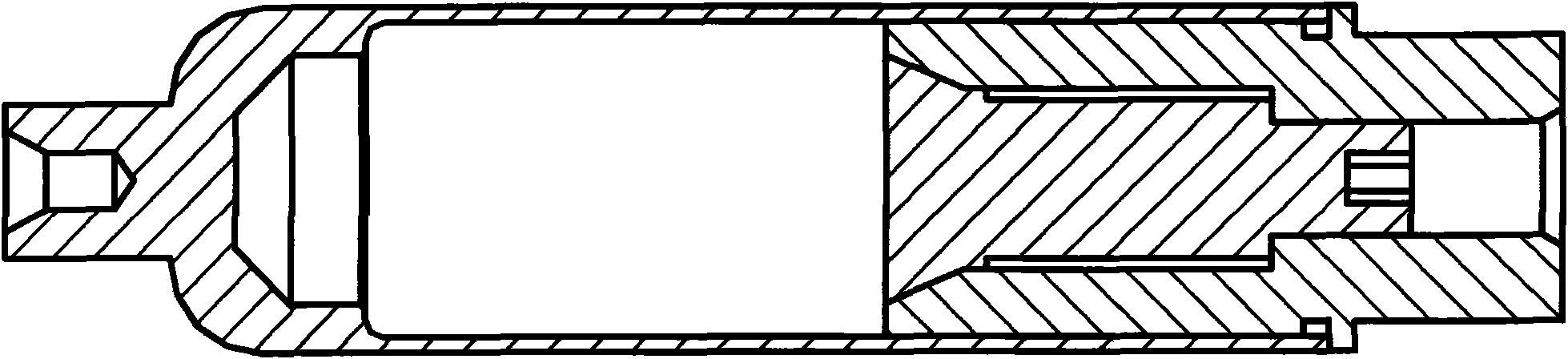

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

[0021] The long-axis thin-walled part of the present invention is processed through blanking, quenching and tempering treatment, rough machining, high and low temperature aging, semi-finishing, finishing and inspection processes, and the specific processing steps are as follows.

[0022] (1) Blanking: select the required metal material, and cut the material according to the processing requirements and the process handle required by the parts;

[0023] (2) Quenching and tempering treatment: eliminate the internal stress of the material, so that the material structure of the part can obtain higher strength, hardness and considerable toughness, and improve the cutting performance of machining;

[0024] (3) Rough machining: remove the large machining allowance of the part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com