Gear grinding clamping device of planetary gear of wind power generation device

A technology for wind power generation equipment and planetary gears, which is applied to gear tooth manufacturing devices, mechanical equipment, components with teeth, etc., can solve the problems of increasing the workload of workpiece clamping and alignment, difficulty, and low efficiency, and achieve shortening Time to adjust accuracy, improvement of processing efficiency, and short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

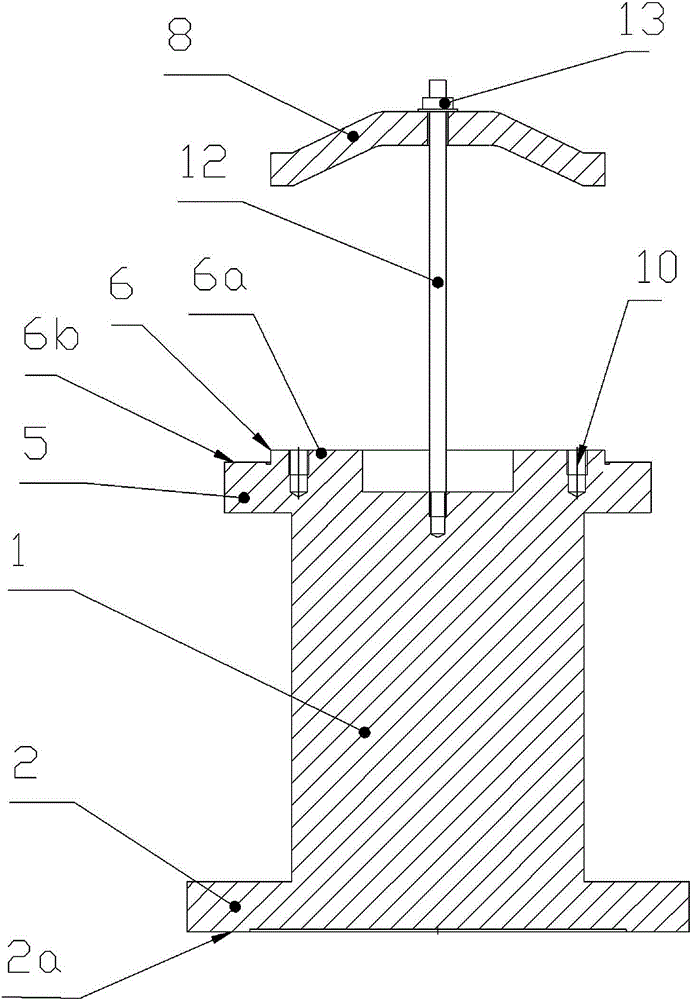

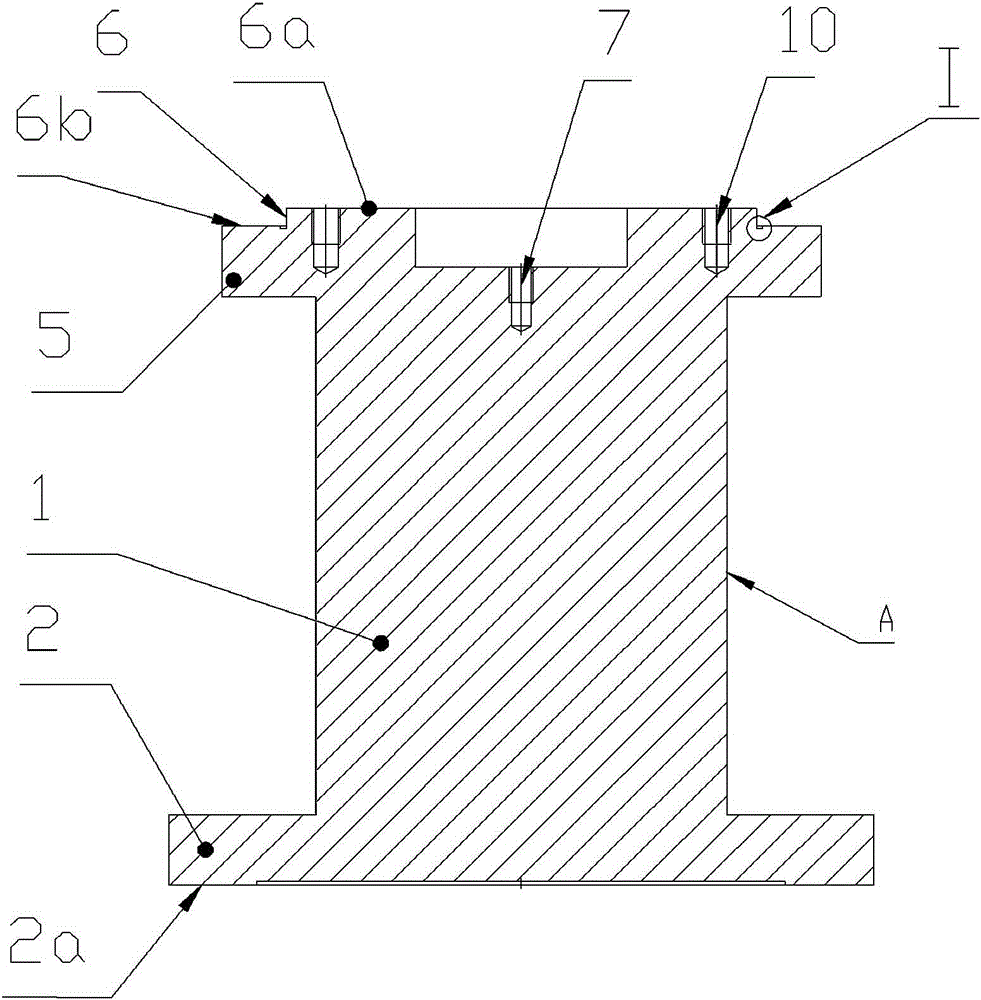

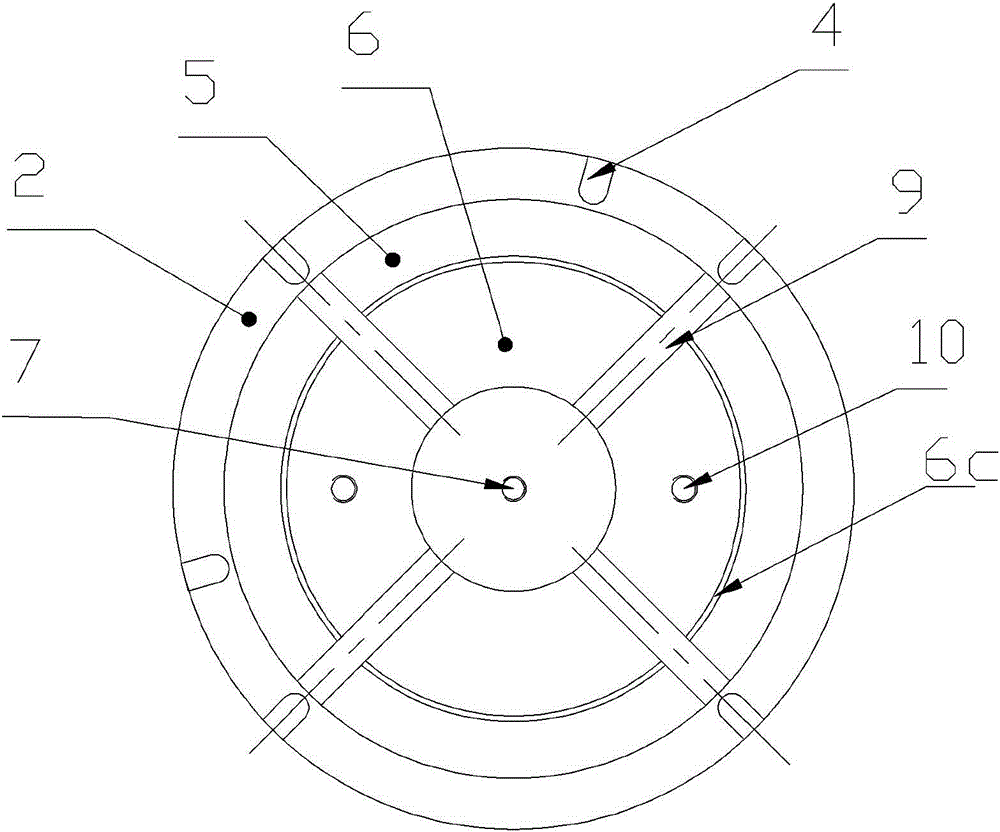

[0020] see figure 1 place Figure 6 , an embodiment of a gear grinding and clamping device for a planetary gear of a wind power generating equipment, the gear grinding and clamping device of a planetary gear of a wind power generating equipment comprises: a fixture seat 1 for supporting a workpiece, an axis positioning pressure block 8, and The screw 12 connecting the two. The material of the fixture seat 1 for supporting the workpiece is cast iron QT400, which can avoid the problem of deformation caused by long-term use. The fixture base 1 is a stepped cylinder, and the bottom of the stepped cylinder is an installation and positioning base 2 with a diameter larger than that of the middle cylinder, and the circumference of the installation and positioning base 2 is evenly provided with a plurality of radial openings for installation and fixing Slot 4. The number of radial opening slots 4 for installation and fixing can be divided into three symmetrical groups and four symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com