Aero-engine air inlet guide vane and rocker arm combined drilling device and using method thereof

An aero-engine and guide vane technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low product qualification rate, difficult clamping and unstable quality, etc. The effect of high positioning accuracy and reduced clamping difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

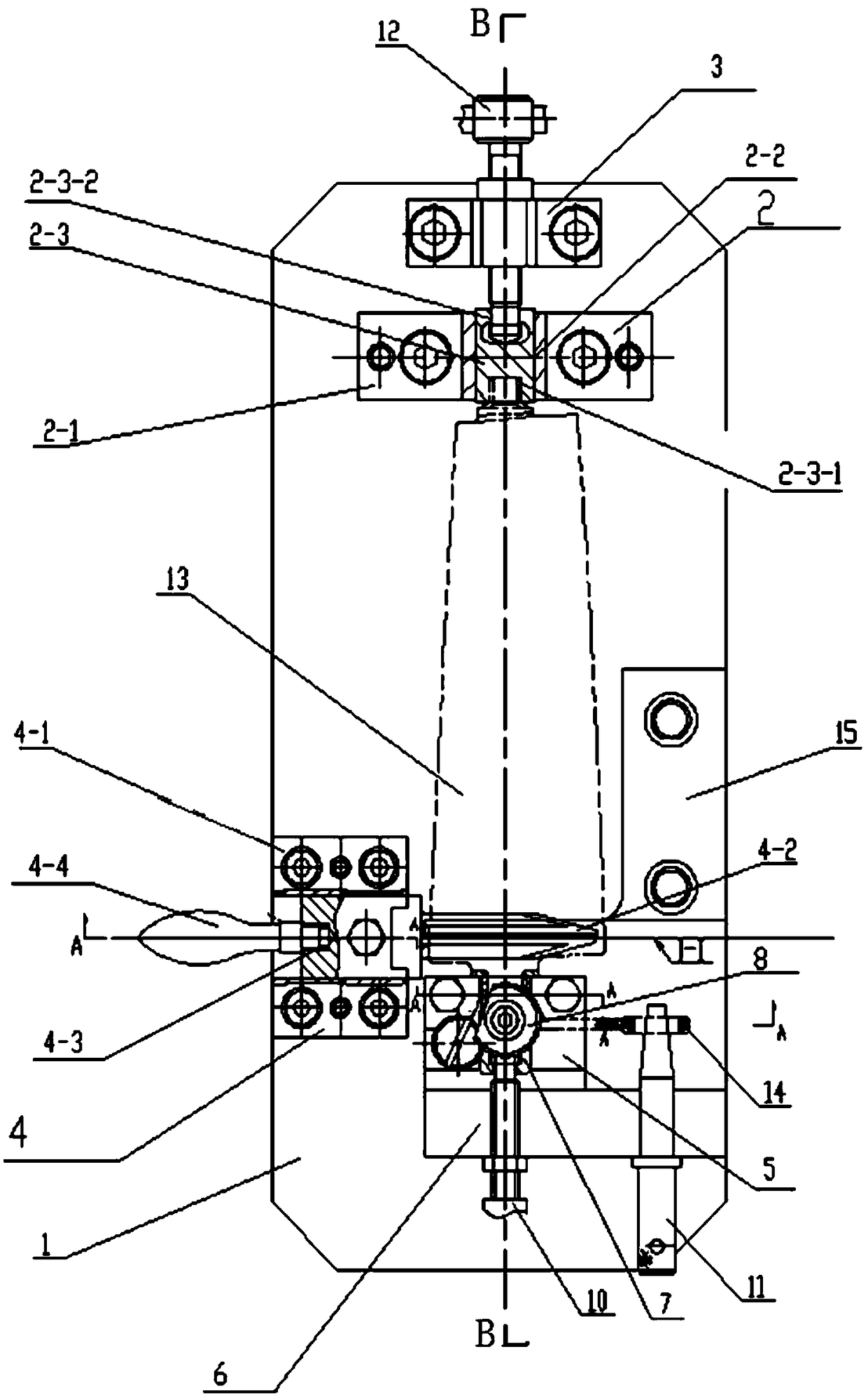

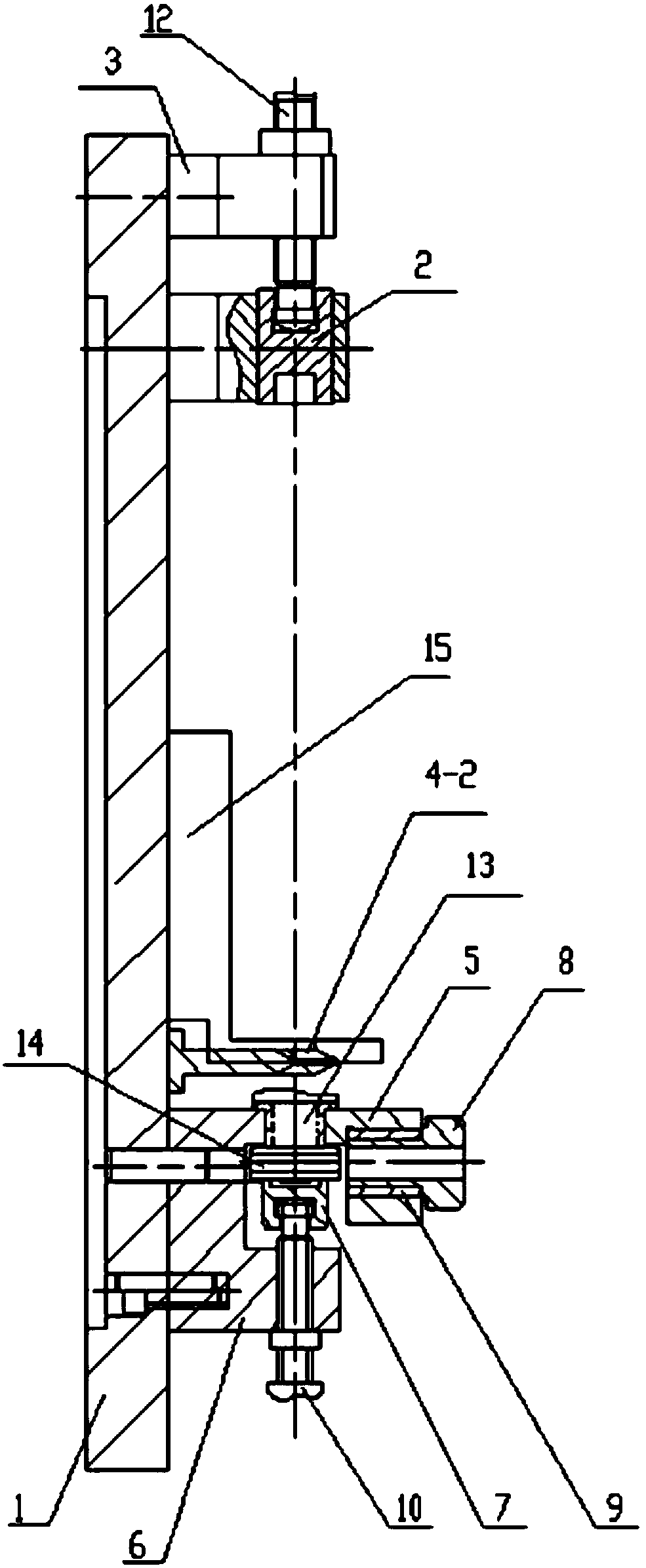

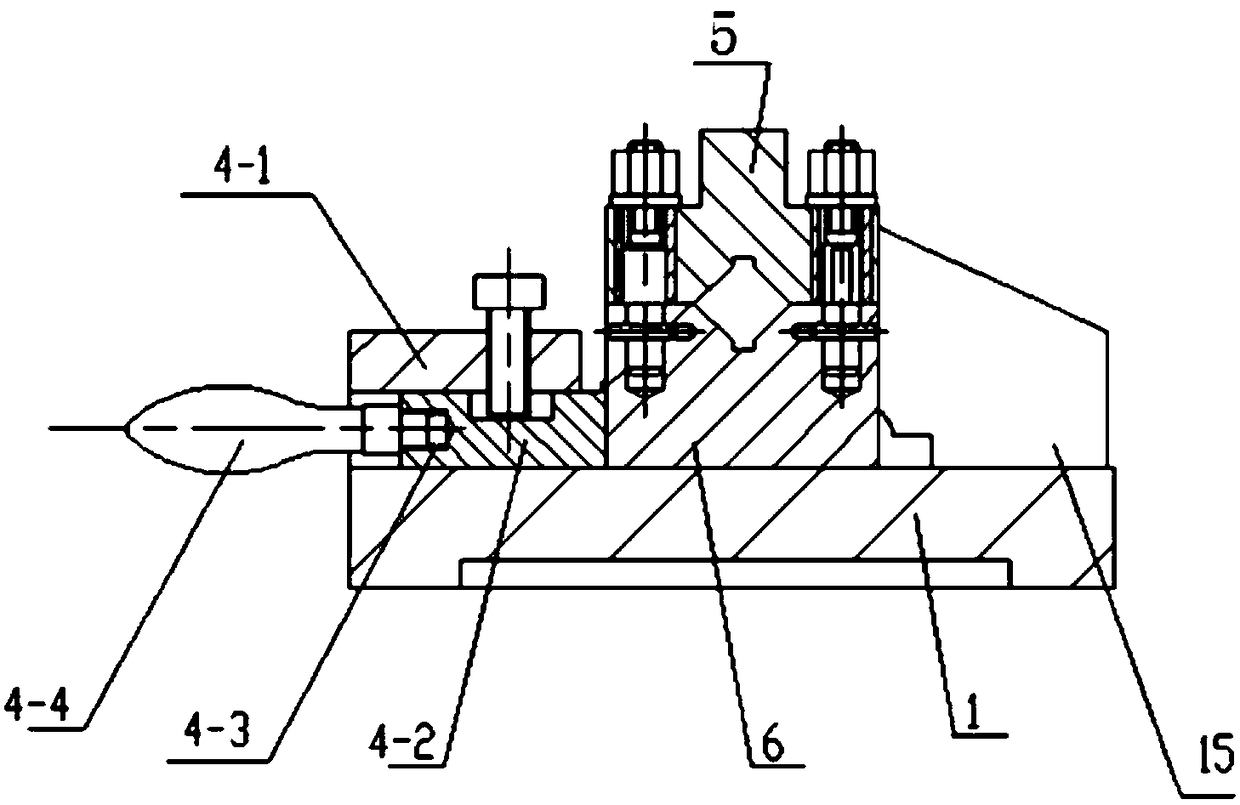

[0035] The structure and use of the aero-engine air intake guide vane and rocker combined drilling device according to the present invention will be further described below with reference to the accompanying drawings.

[0036] In this embodiment, the technical requirement that the included angle between the line of the I-I section of the air intake guide vane of the aeroengine and the center line of the rocker arm should meet is 35 ° 15' ± 5', see Figure 16 .

[0037] The structure of the combined drilling device of air intake guide vane and rocker arm of the aero-engine described in this embodiment is as follows: figure 1 , figure 2 , image 3 As shown, it mainly consists of base plate 1, rear journal axial positioning assembly 2, front journal axial positioning member 6, rear journal adjustment assembly, axial compression screw 10, pressure block 7, angular positioning assembly 4, Compress template 15, drill template 5, drill sleeve 8, bushing (9) and rocker arm positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com