Polishing equipment for multi-axis free-form surface optical element and working method

An optical element, free technology, used in grinding/polishing equipment, optical surface grinder, metal processing equipment, etc., can solve the problem of difficult processing and manufacturing of multi-axis free-form optical elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

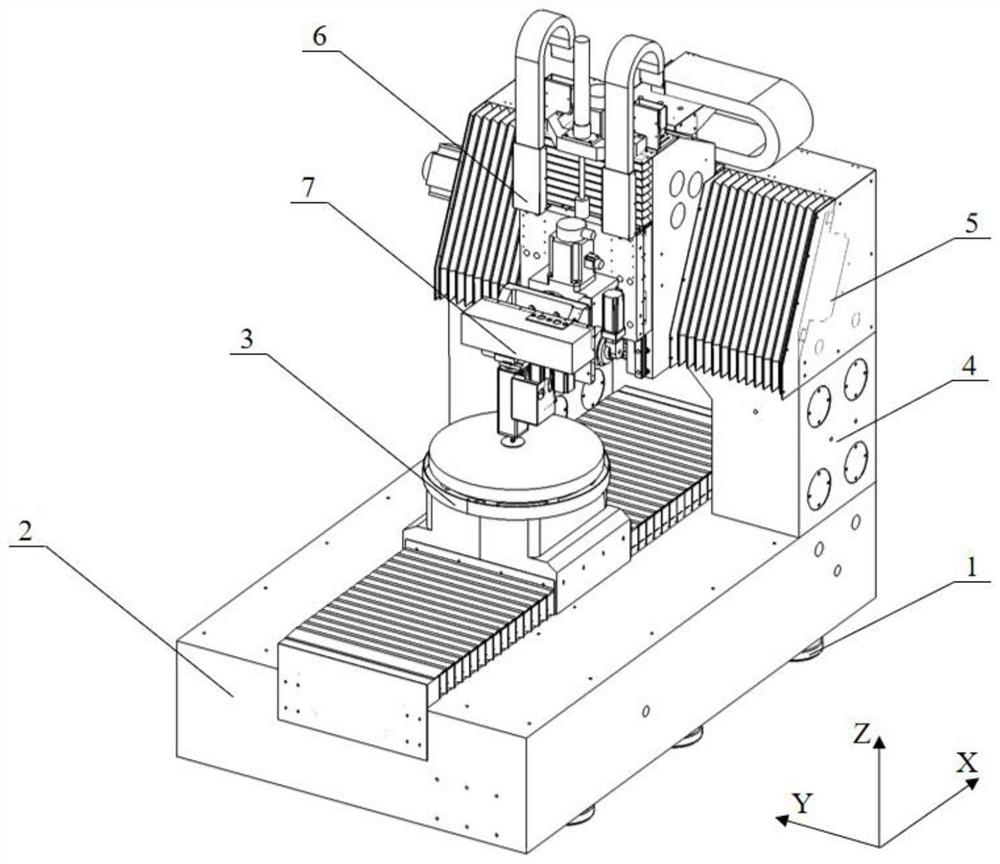

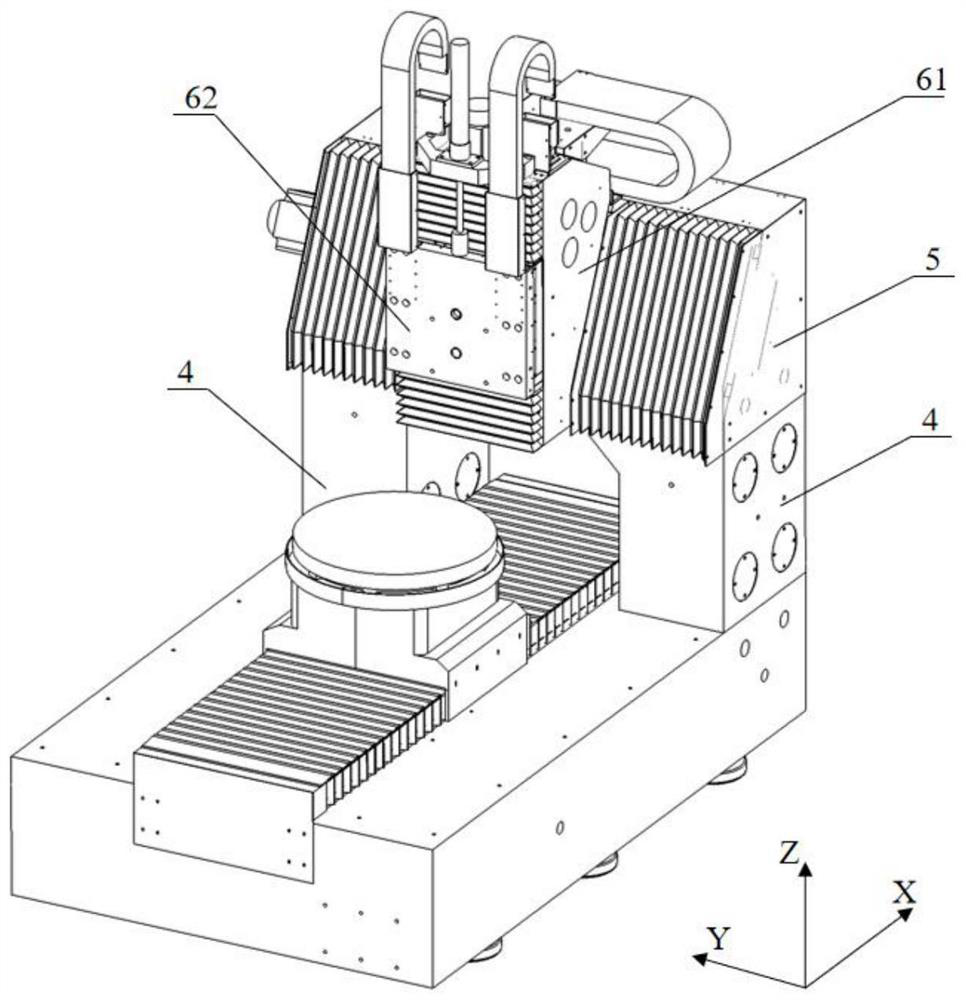

[0027] Such as Figure 1-7 As shown, the polishing equipment for multi-axis free-form surface optical components includes: bed 2, workpiece clamping platform 3, column 4, beam 5, linear motion mechanism 6, multi-axis free-form surface polishing device 7,

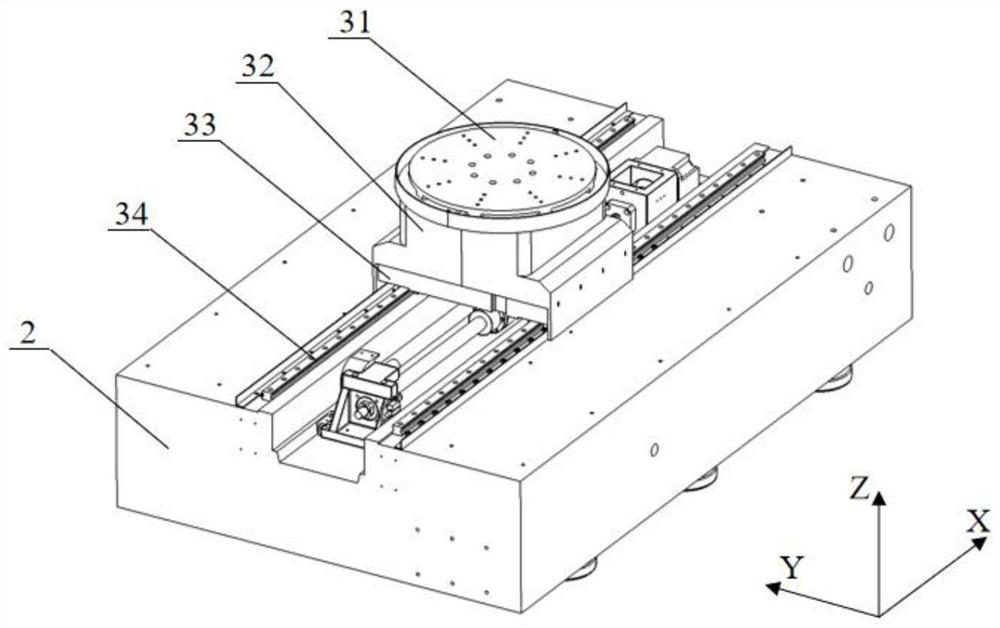

[0028] The bed 2 is placed horizontally, the workpiece clamping platform 3 is installed on the bed and includes: fixture 31, high-precision turntable 32, X-axis linear motion sliding plate 33 and X-axis linear motion guide rail 34, and fixture 31 is fixed on the high-precision turntable 32 , the workpiece to be processed is placed horizontally on the high-precision turntable 32 through the fixture. The high-precision turntable is fixed on the X-axis linear motion slide plate 33, and performs high-precision servo rotation around the C axis perpendicular to the bed. The X-axis linear motion slide plate is installed On the X-axis linear motion guide rail and perform linear motion along the X-axis direction;

[0029] The column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com