Automatic discharge device for back spindle

An automatic nesting and spindle technology, applied in positioning devices, clamping, support, etc., can solve problems affecting processing efficiency and complicated operating procedures, achieve good nesting effects, avoid human errors, and prevent excessive actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

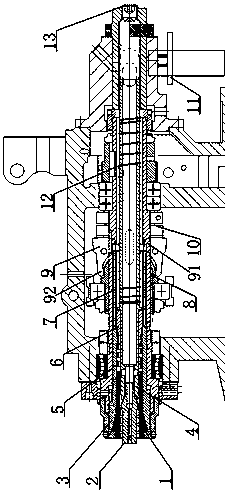

[0015] see figure 1 , an automatic discharge device for the back spindle, comprising a collet 1, a ejector pin 2, a collet cover 3 and a bar material inlet 13, the ejector pin 2 is located in the collet 1, and the collet 1 is located in the collet sleeve 3, and one end of the ejector pin 2 is threaded, and the ejector pin 2 is threadedly connected with the push rod-4, and the length of the ejector pin 2 can be appropriately changed according to needs, but it should not be too long , otherwise it will affect the clampable length of the bar, the collet sleeve 3 is threaded with the limit sleeve 6, and a return spring 5 is arranged between the collet 1 and the limit sleeve 6, and the return spring 5 The cross-section of the chuck is rectangular to ensure the reliable reset of the collet cover. One end of the collet cover 3 near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com