Automatic riveting machine and usage method thereof

A riveting machine and riveting technology, applied in the field of automated machinery, can solve problems such as low production efficiency, large safety hazards, and cumbersome steps, and achieve the effects of improving product production efficiency, avoiding safety hazards, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

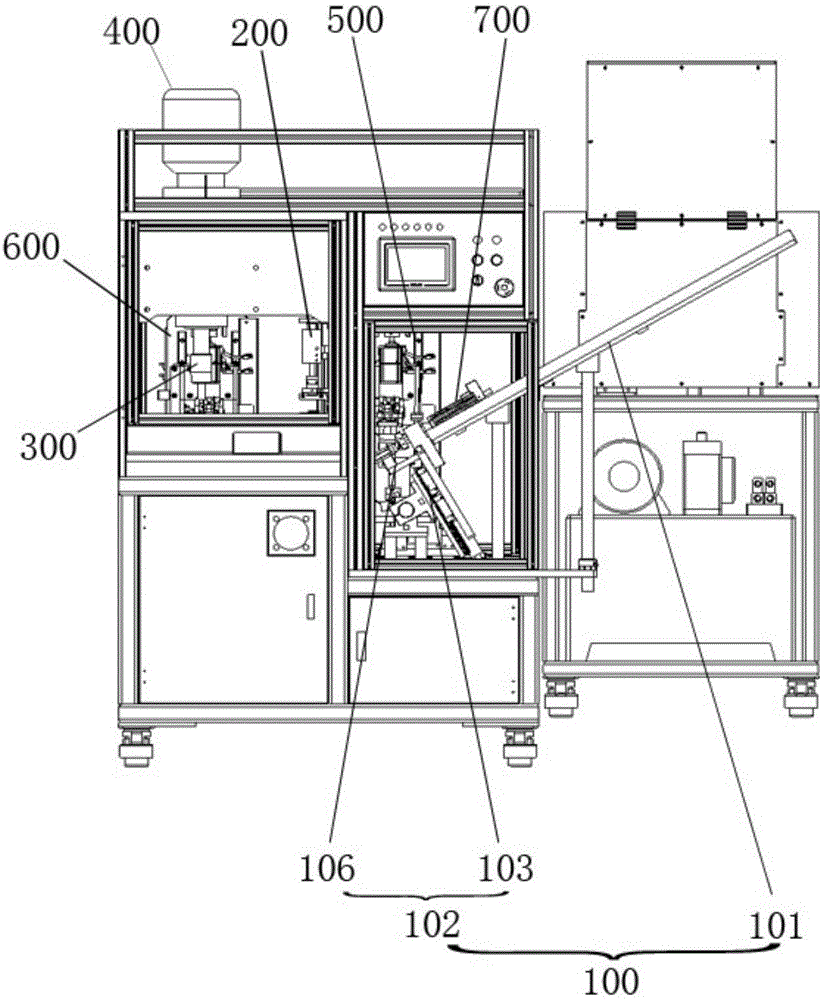

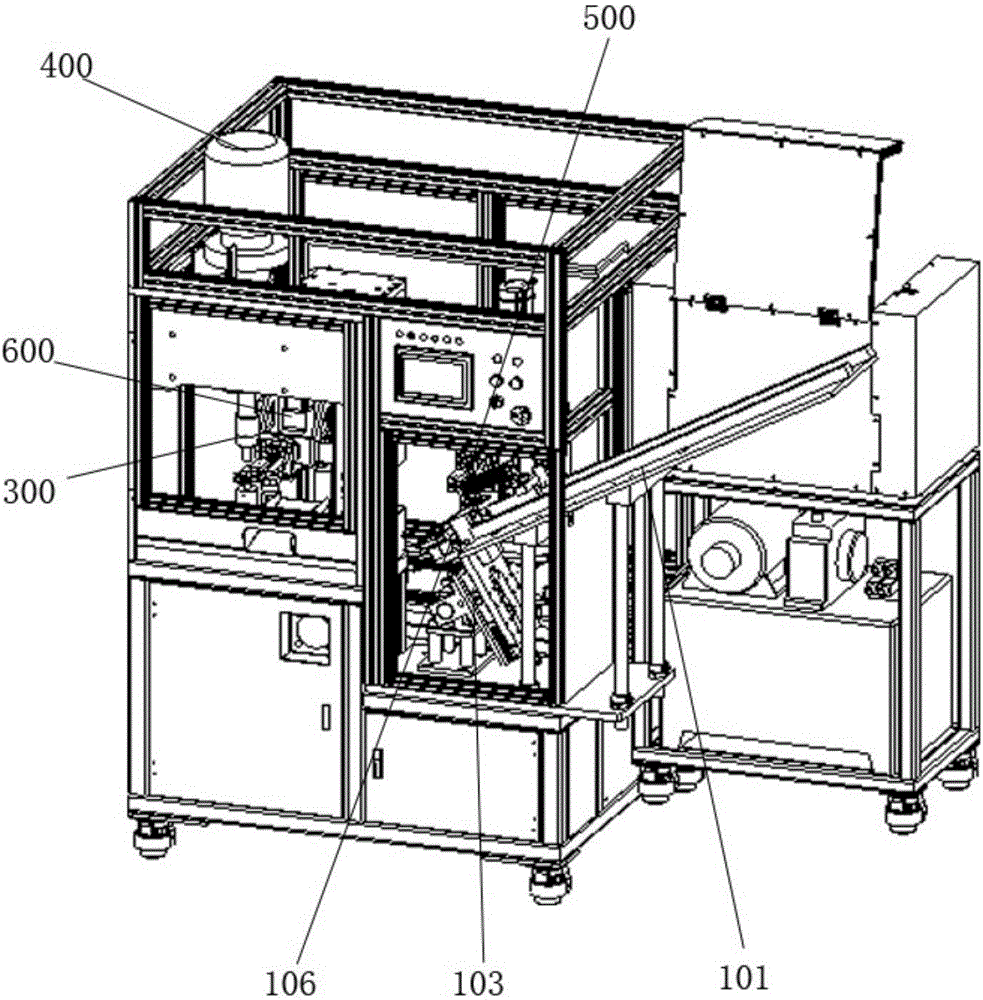

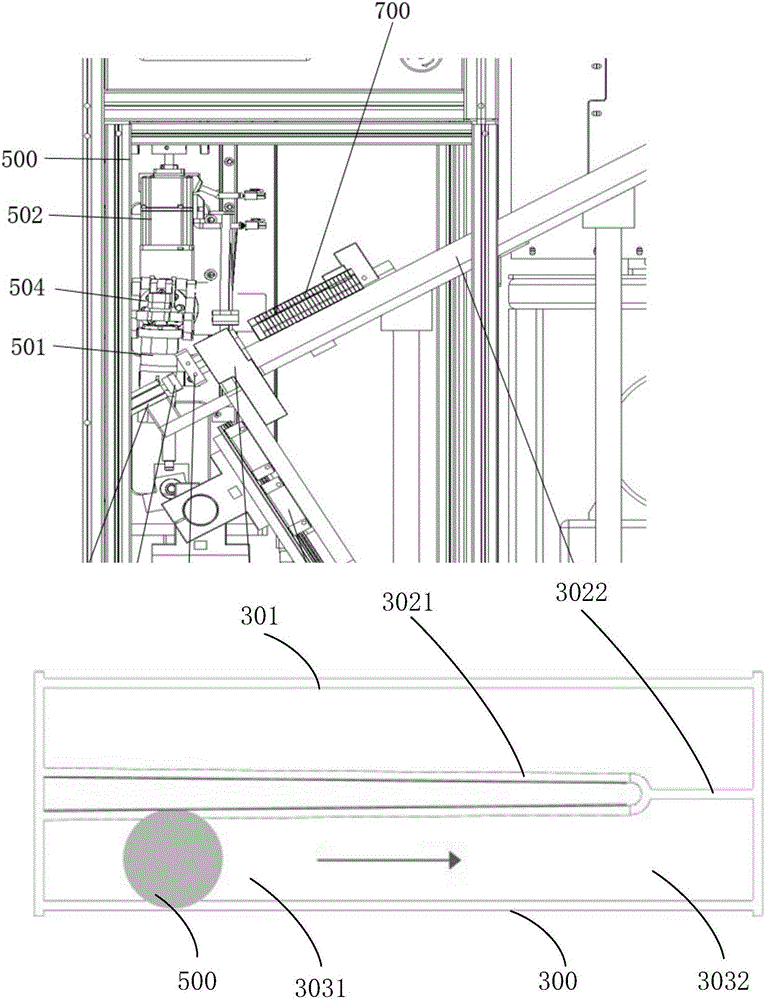

[0031] see Figure 1-4 , the present invention provides an automatic riveting machine, including a feeding device 100, a riveting device 200, a riveting device 300, a vibrating plate 400 for placing accessories 800 in advance and transferring them to the riveting device 200, and a first device for grabbing a workpiece 700 A grasping device 500 and a second grasping device 600. In this embodiment, the above-mentioned devices are connected to the main control center, and the automatic operation of the entire riveting machine is realized through the intelligence of the main control center. At the same time, the user can also use the main control center The center realizes the parameter setting of the device. The feeding device 100 includes a feeding chute 101 for placing the workpiece 700 in advance and a conveying device 102 for transferring the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com