Stirring device for food processing

A stirring device, food processing technology, applied in the direction of processing meat, poultry processing, mixer accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

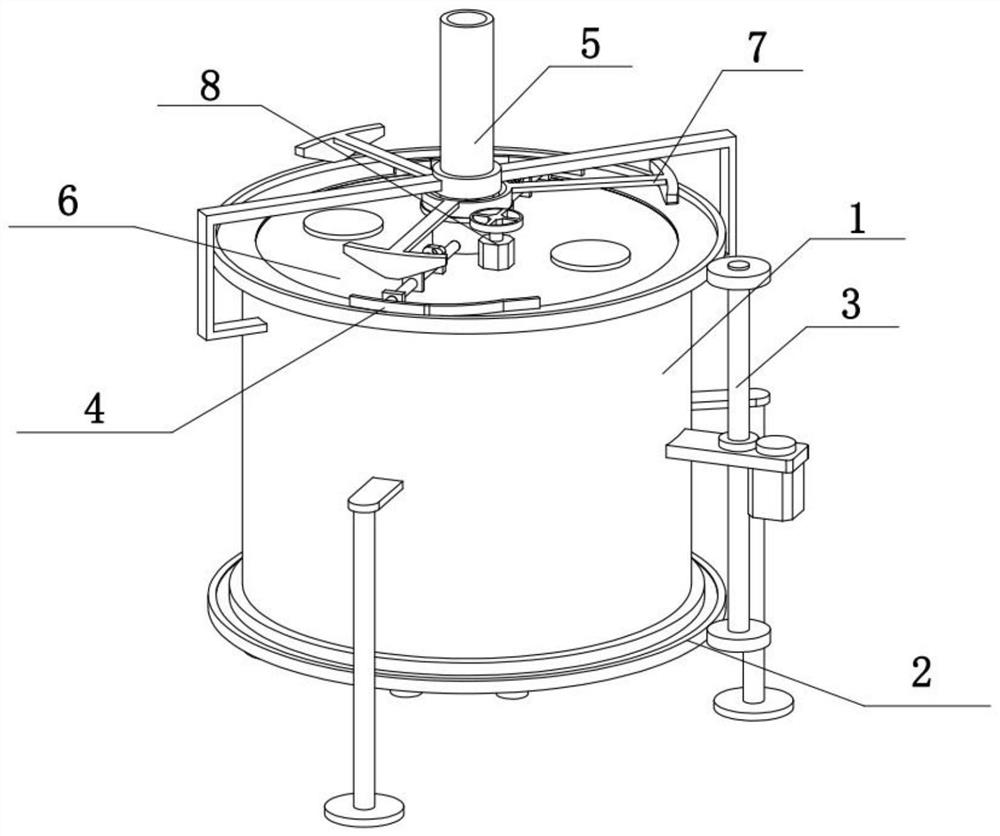

[0031] Combine below Figure 1-9 Description of this embodiment, a stirring device for food processing, including a support assembly 1, a filling assembly 2, an adjustment assembly 3, a switch assembly 4, a stirring assembly 5, a feeding assembly 6, a cleaning assembly 7 and a driving assembly 8, the filling assembly Component 2 is rotatably connected to the support component 1, the adjustment component 3 is fixedly connected to the support component 1, the switch component 4 is rotatably connected to the upper end of the support component 1, the filling component 2 and the switch component 4 are both engaged with the adjustment component 3 for transmission, and the lower The material assembly 6 is connected to the support assembly 1, the stirring assembly 5 is fixedly connected to the support assembly 1, the cleaning assembly 7 is rotatably connected to the blanking assembly 6, the cleaning assembly 7 and the blanking assembly 6 are meshed for transmission, and the stirring as...

specific Embodiment approach 2

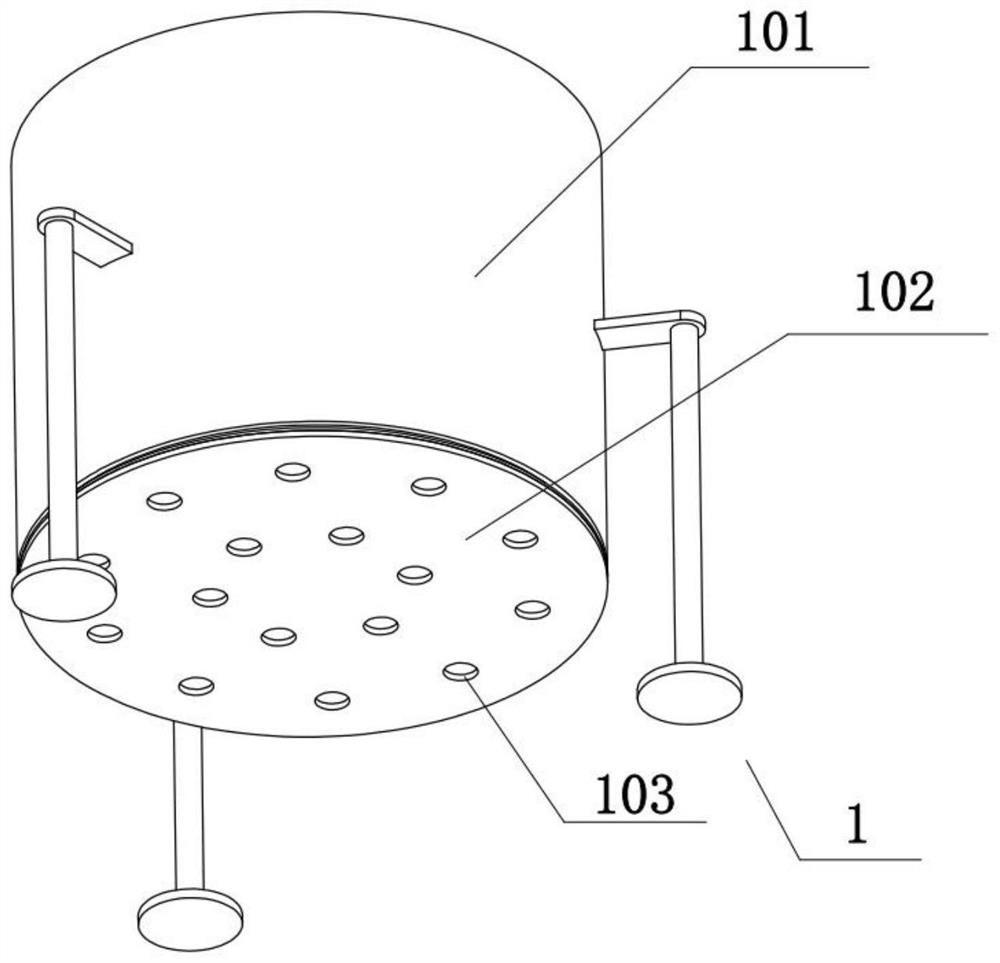

[0034] Combine below Figure 1-9 To illustrate this embodiment, the support assembly 1 includes a processing barrel 101, a material retaining plate 102 and a blanking hole 103, the lower end of the processing barrel 101 is fixedly connected with a material retaining plate 102, and the material retaining plate 102 is provided with a plurality of blanking holes 103.

specific Embodiment approach 3

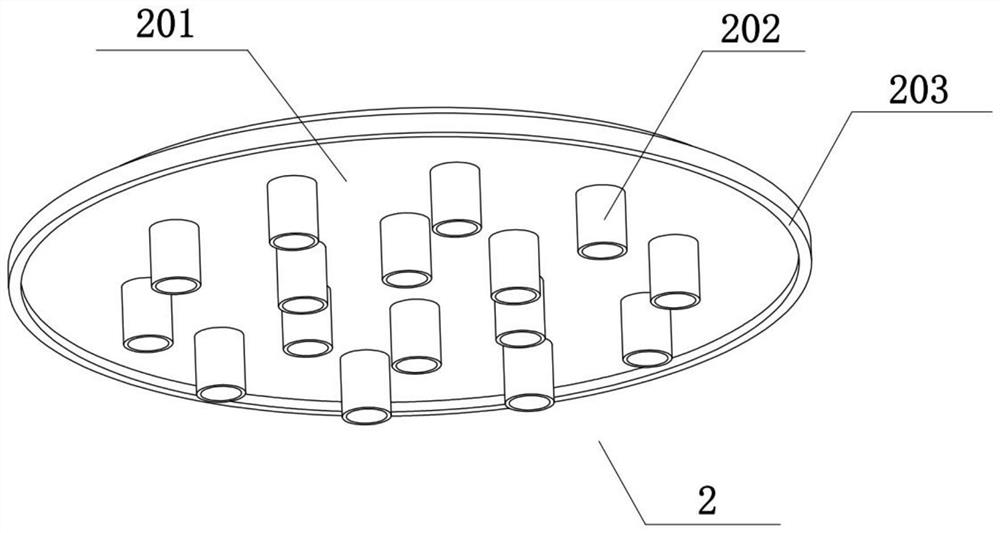

[0036] Combine below Figure 1-9 To illustrate this embodiment, the filling assembly 2 includes a filling plate 201, a filling pipe 202 and a filling ring gear 203, the filling plate 201 is rotatably connected to the lower end of the processing barrel 101, and the filling plate 201 is fixedly connected with multiple There are a plurality of filling tubes 202 and a plurality of filling tubes 202 corresponding to a plurality of feeding holes 103 respectively, and a filling ring gear 203 is fixedly connected to the filling plate 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com