Argon tungsten-arc welding clamp for butt joint of thin steel strips and using method

A technology of argon tungsten arc welding and thin steel, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as insufficient butt joint of steel strips, overcome uneven stress on test pieces, facilitate installation and disassembly, Uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

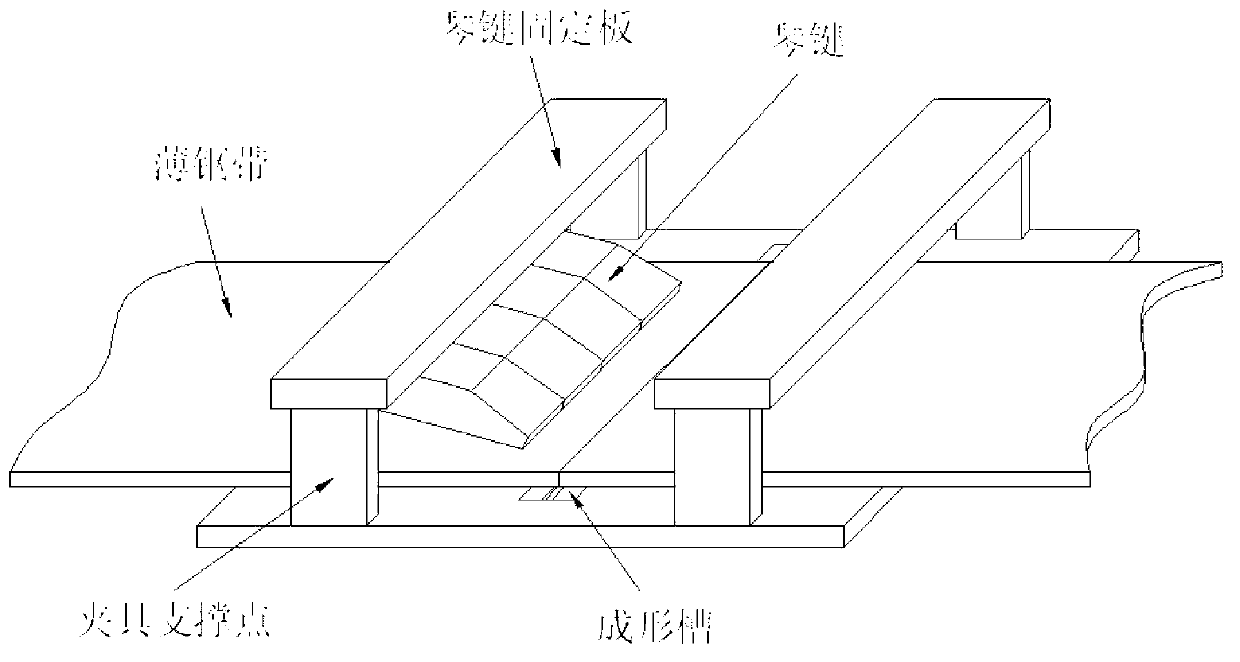

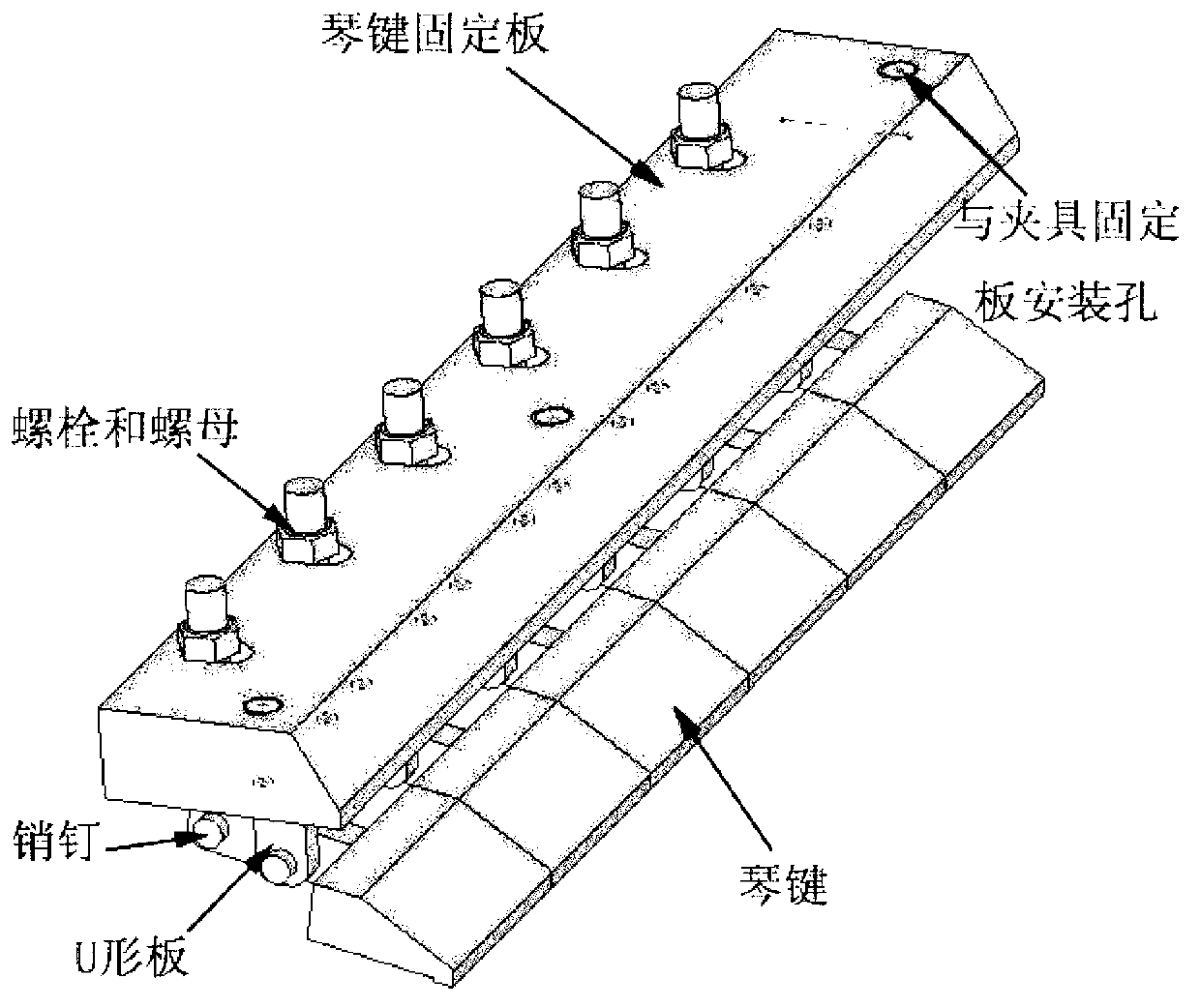

[0047] Thin steel strip butt tungsten argon arc welding fixture, including work table, cylinder connector, fixture fixing plate and master form, specifically as follows:

[0048] 1. Countertops and profiles

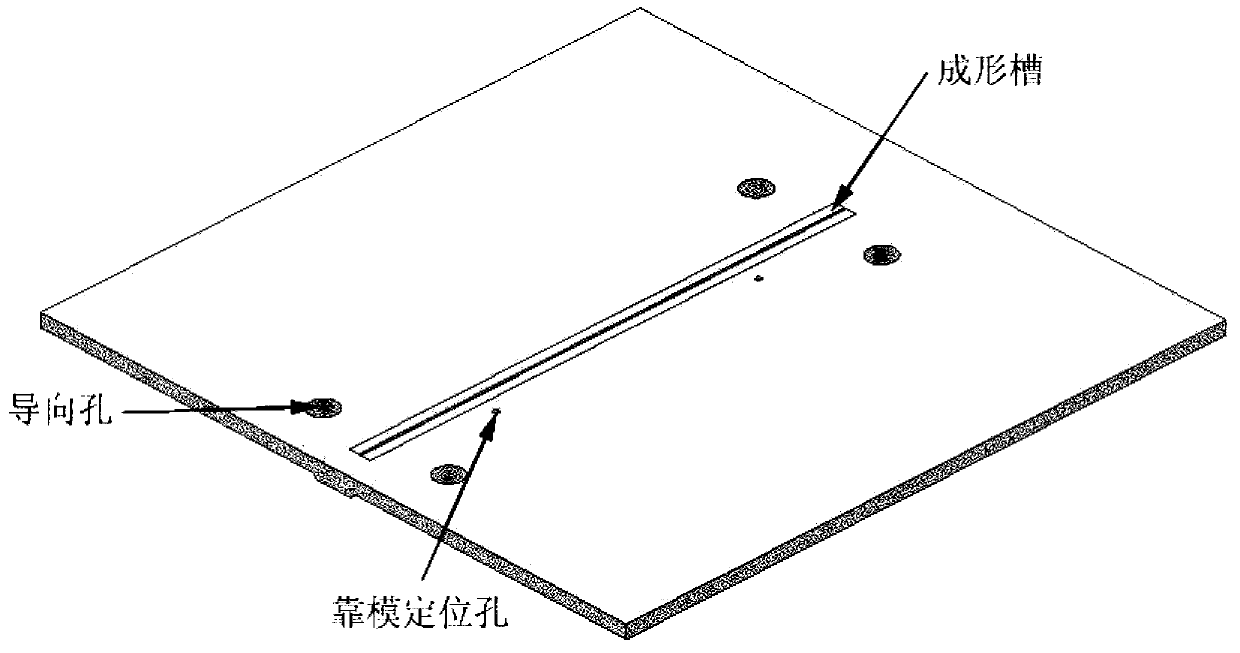

[0049] The center of the worktable is provided with a forming groove, and the left and right sides of the forming groove are symmetrically provided with guide holes; one side of the forming groove is provided with a pattern positioning hole, and the distance between the center of the pattern positioning hole and the middle of the forming groove is It is equal to the distance from the center of the boss below the cam to one edge of the cam, so that when the cam is fixed in the positioning hole, the other edge of the cam is just in the center of the forming groove.

[0050] Such as image 3 As shown, there are two cylindrical bosses at the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com