Device for clamping eccentric parts

A technology of eccentricity and parts, which is applied in the direction of positioning devices, auxiliary devices, tool holder accessories, etc., can solve the problems of unsuitable batch production of eccentric parts, high scrap rate, and difficulty in workpiece clamping, so as to expand the scope of application, Improve work efficiency and ensure the effect of clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

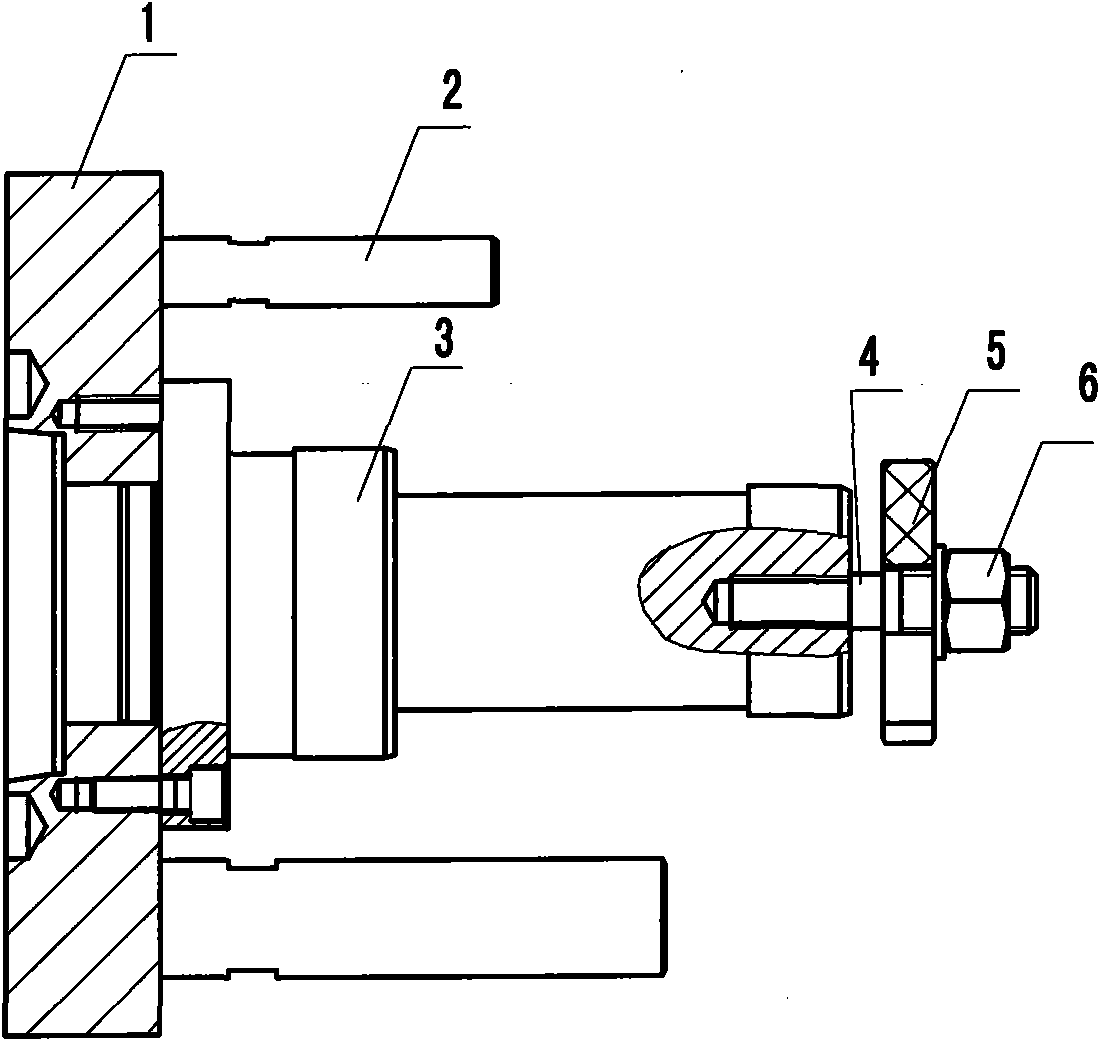

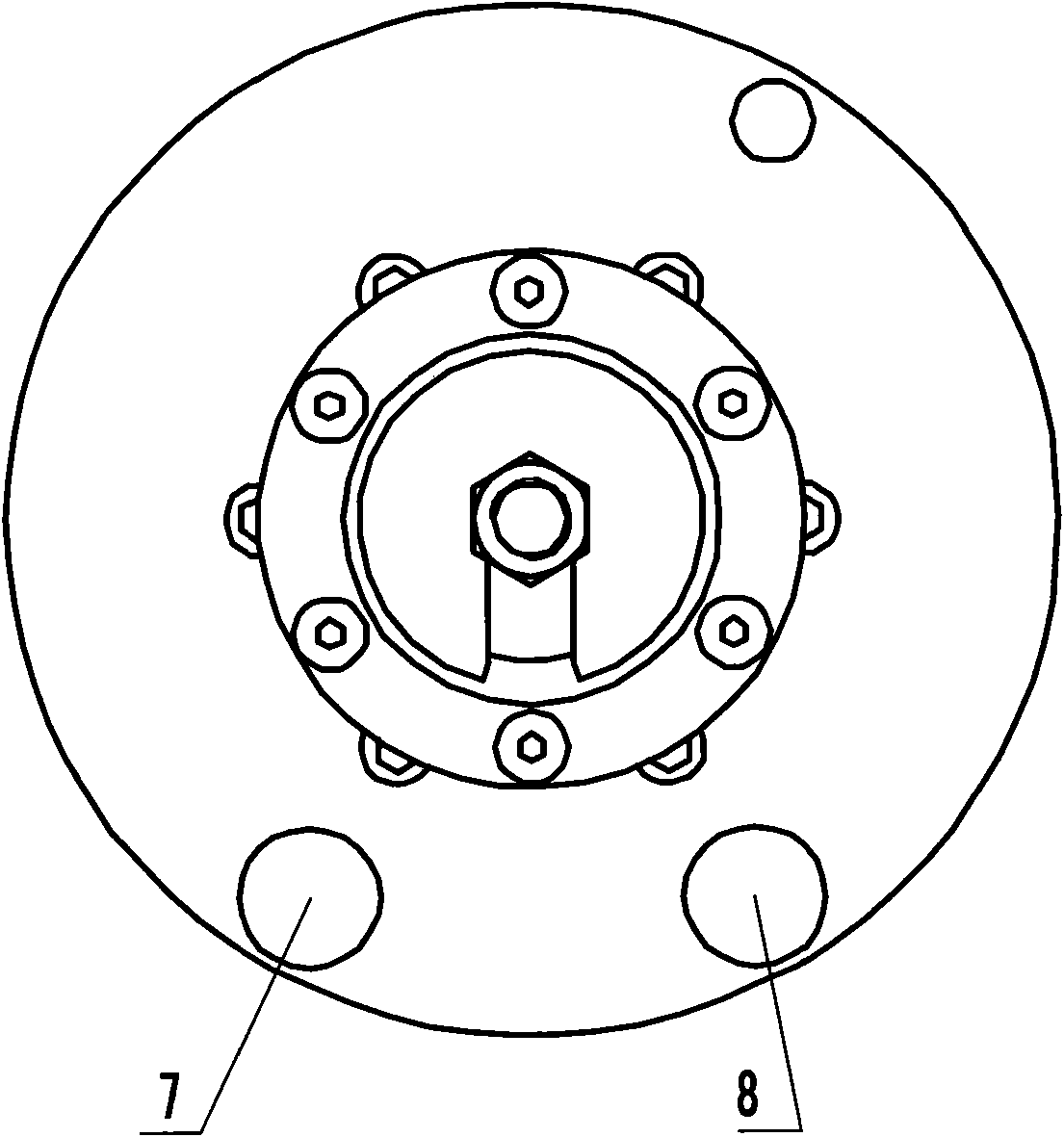

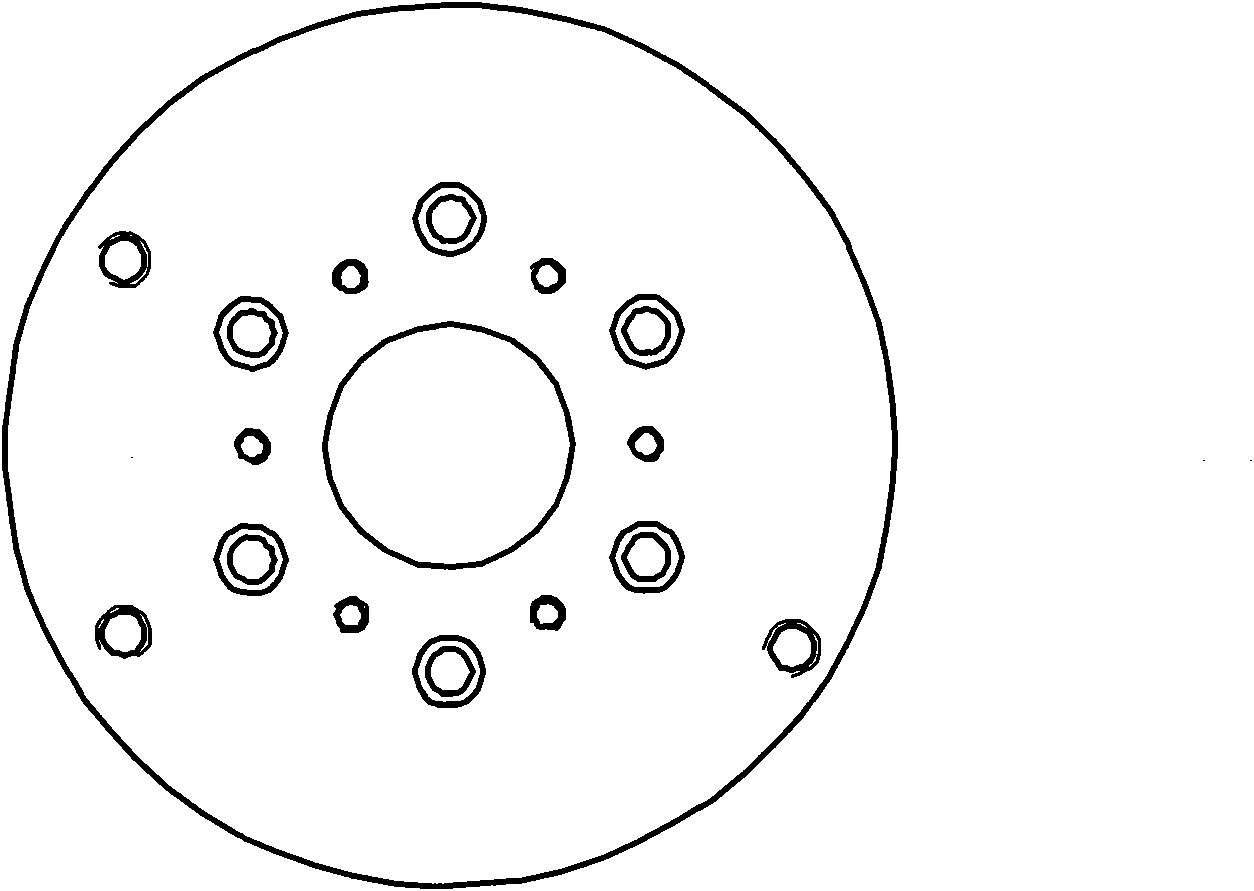

[0015] Such as Figure 1-Figure 4 As shown, the present invention includes a coupling disc 1, a stop pin 2, a mandrel 3, a clamping bolt 4, a split washer 5, a nut 6, a counterweight 7 and a counterweight 8, and the mandrel 3 is embedded in the coupling disc 1. In the hollow inner cavity, it is fixed with bolts, the clamping bolt 4 is threadedly connected with the mandrel 3, and the position of the coupling disc 1 is adjusted with the split washer 5, and the stop pin 2 is installed on the coupling disc 1 to position the workpiece. 1. In the opposite direction of eccentricity, according to different workpieces, two different counterweights 7 and 8 can be installed to balance the workpiece.

[0016] When the present invention is in use, the connecting plate 1 is fixed on the connecting plate of the lathe spindle with bolts, the inner cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com