Hot melting and butt joint equipment of plastic pipeline

A technology for hot-melt butt joint and plastic pipe, applied in the field of pipe joint, can solve the problems of affecting the pipe precision, destroying the flatness, destroying the shape of the pipe, etc., so as to avoid deviation, ensure the clamping accuracy and ensure the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

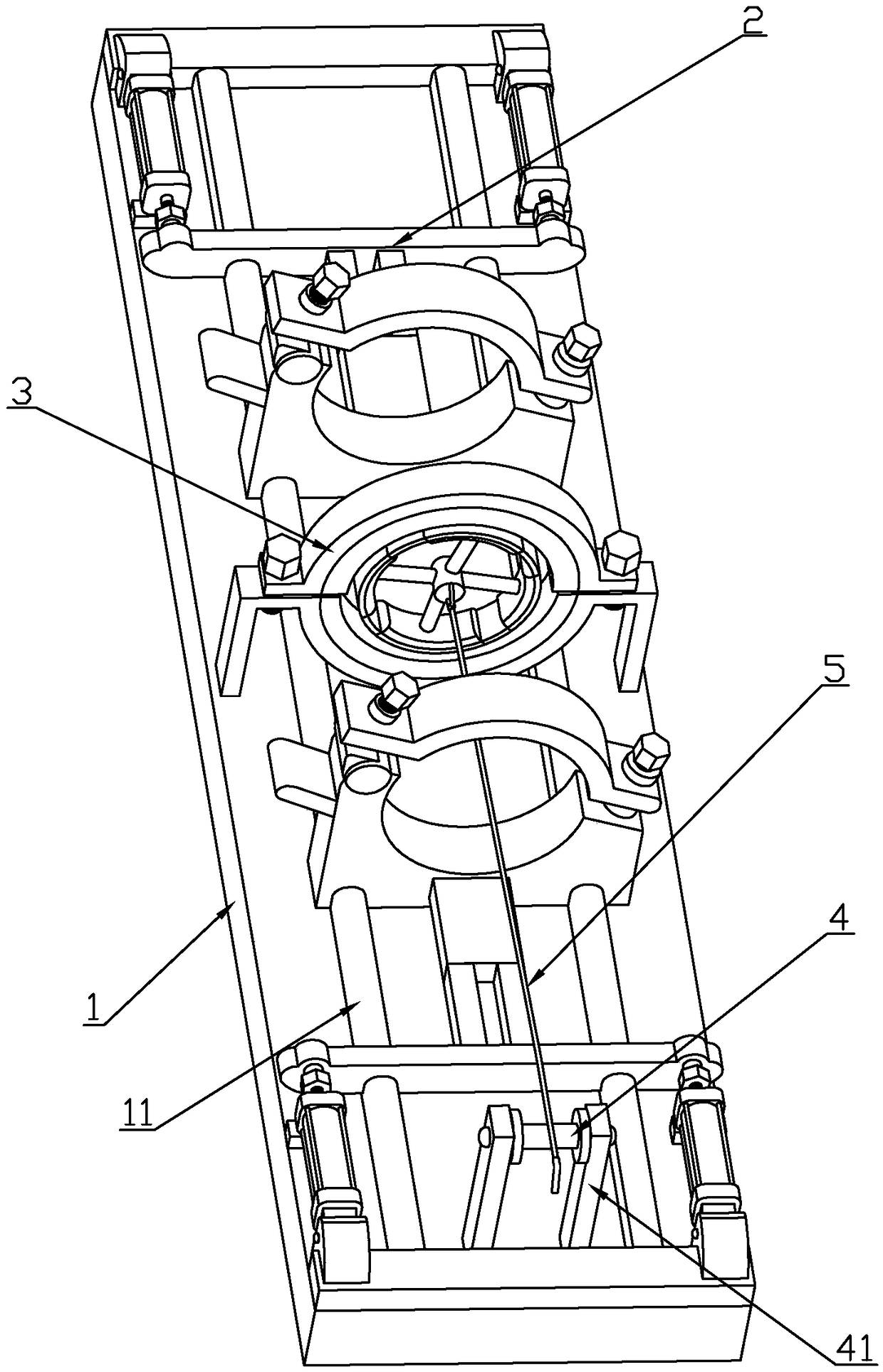

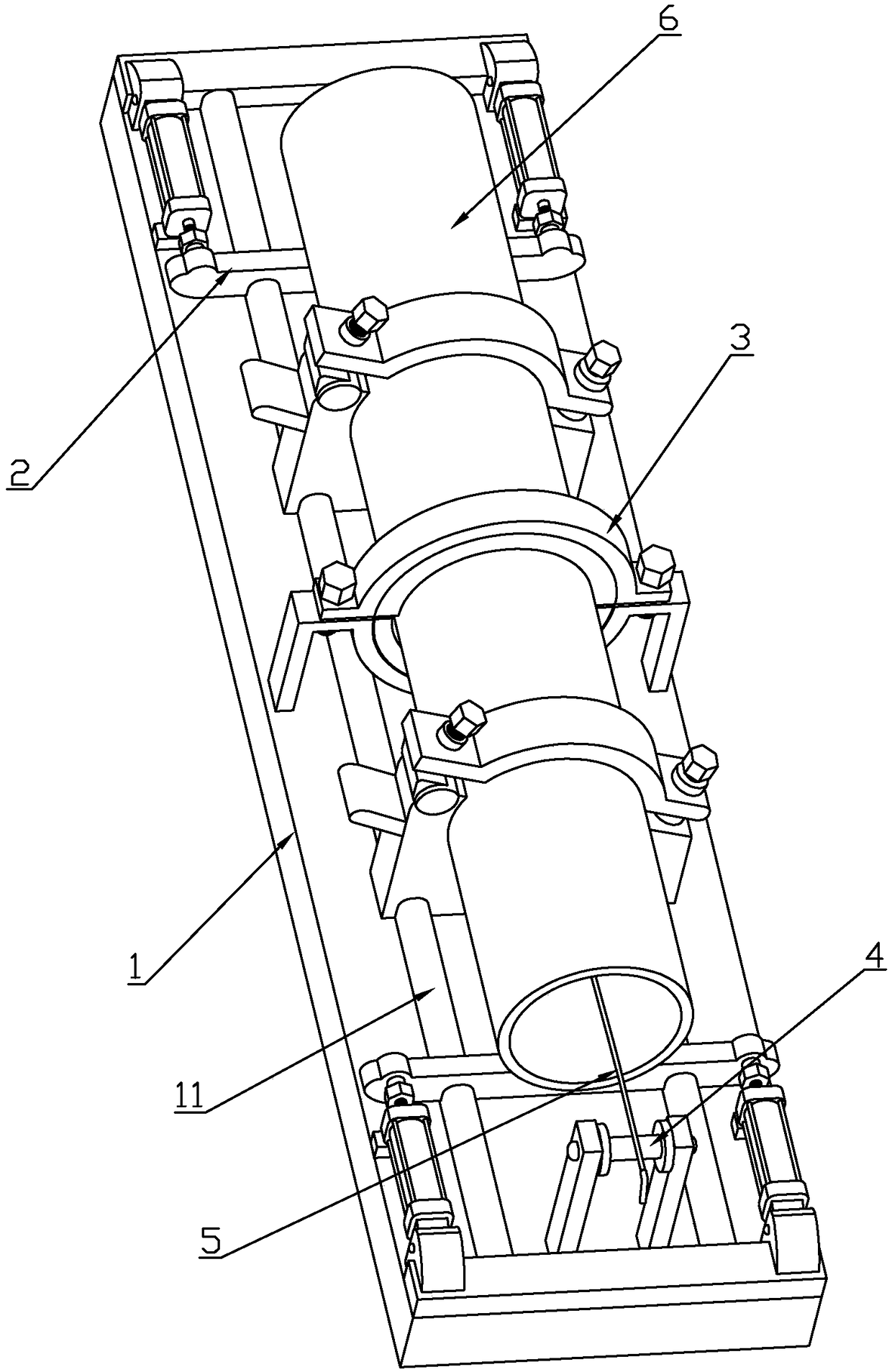

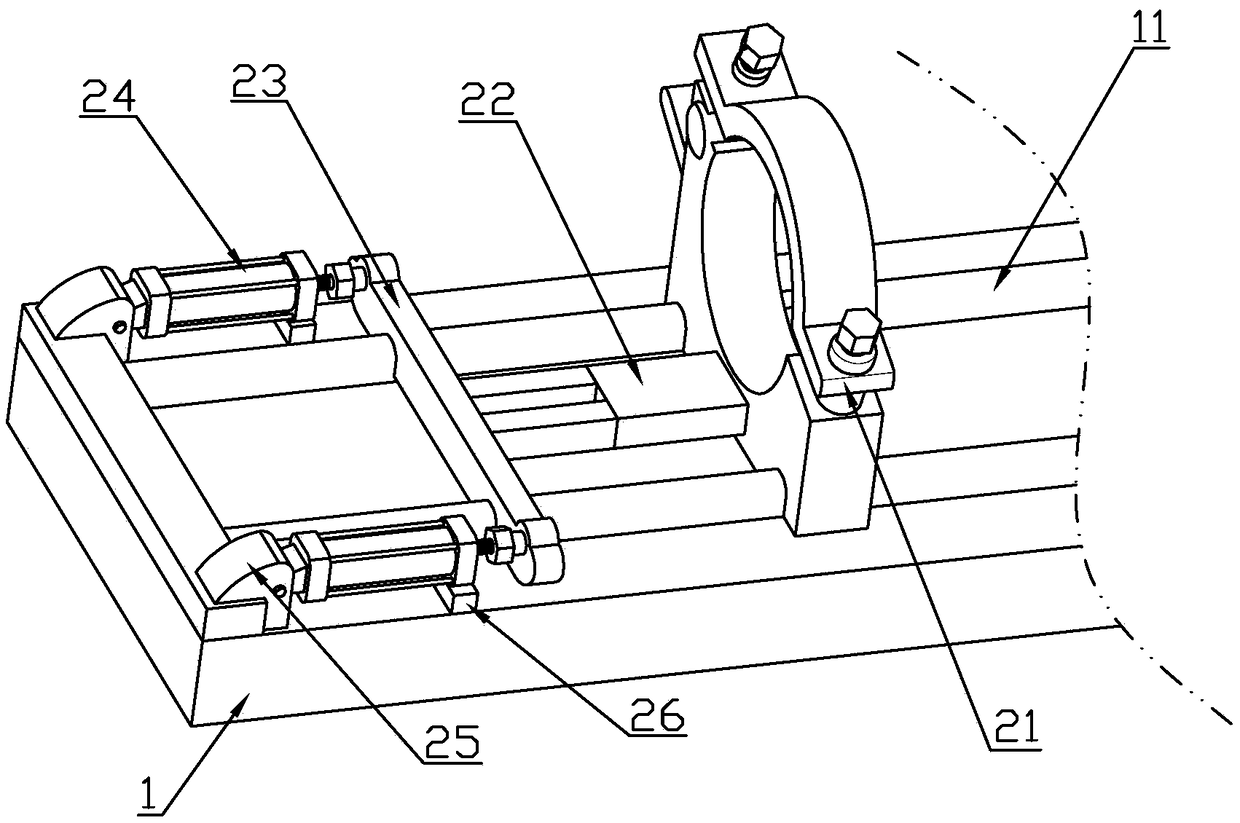

[0024] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-6 , to further specifically describe the technical solution of the present invention.

[0025] A plastic pipe hot-melt docking equipment, including a base 1, a push mechanism 2, a docking mechanism 3, and a traction rope 5, the base 1 is provided with two slide rails 11, and the middle part of the top side of the base 1 is provided with a docking mechanism 3 , the two sides of the docking mechanism 3 are respectively provided with a push mechanism 2, the push mechanism 2 is slidably socketed on the outside of the slide rail 11, and the two push mechanisms 2 respectively clamp the two pipes that need to be connected, and then they are close to each other, and the The joints of the pipes that need to be butted are placed inside the docking mechanism 3, and the butt joint is completed by the docking mechanism 3. The push mechanism 2 moves along the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com