Adjustable clamp for high-speed friction and and wear testing machine

A friction and wear test and adjustable technology, applied in the field of machinery, can solve the problems that the fixture cannot be translated, and the friction and wear test clamping of machining tools cannot be realized, so as to avoid singleness, ensure the clamping accuracy, and improve the positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

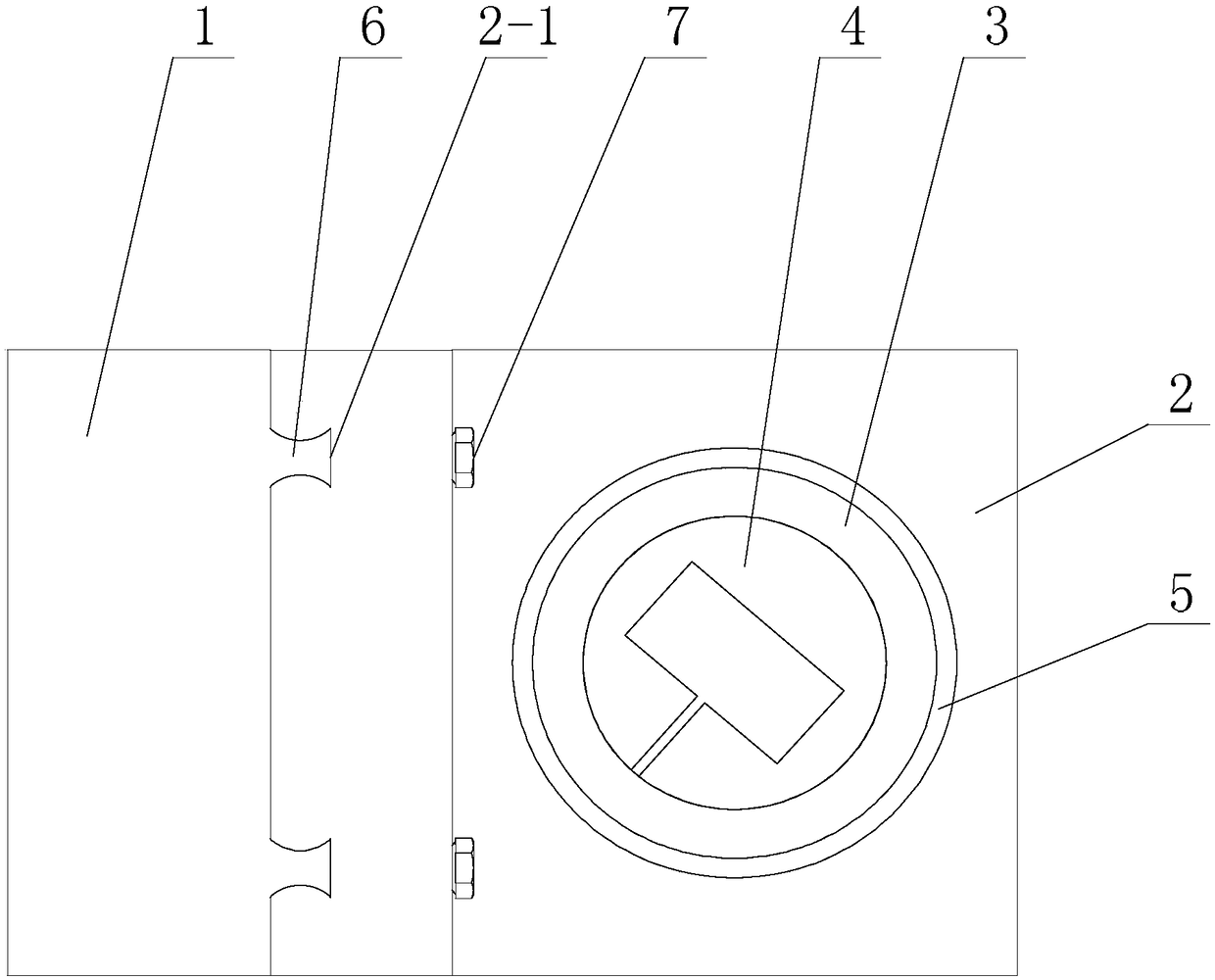

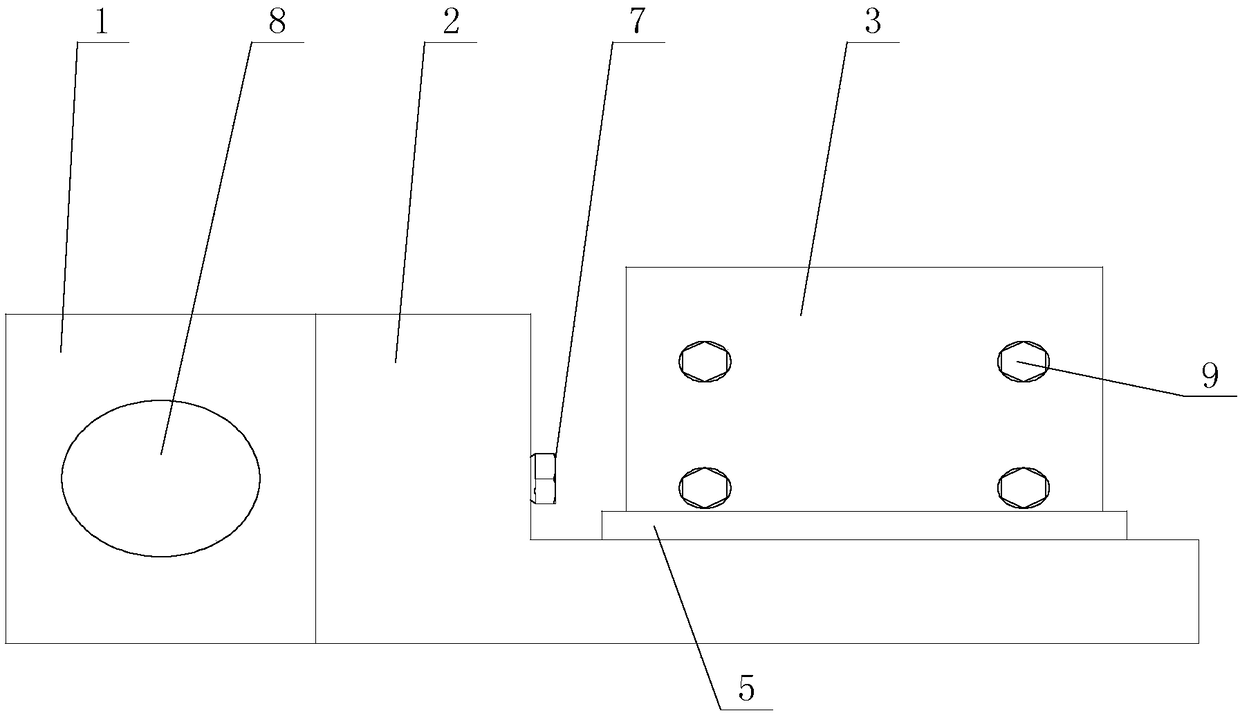

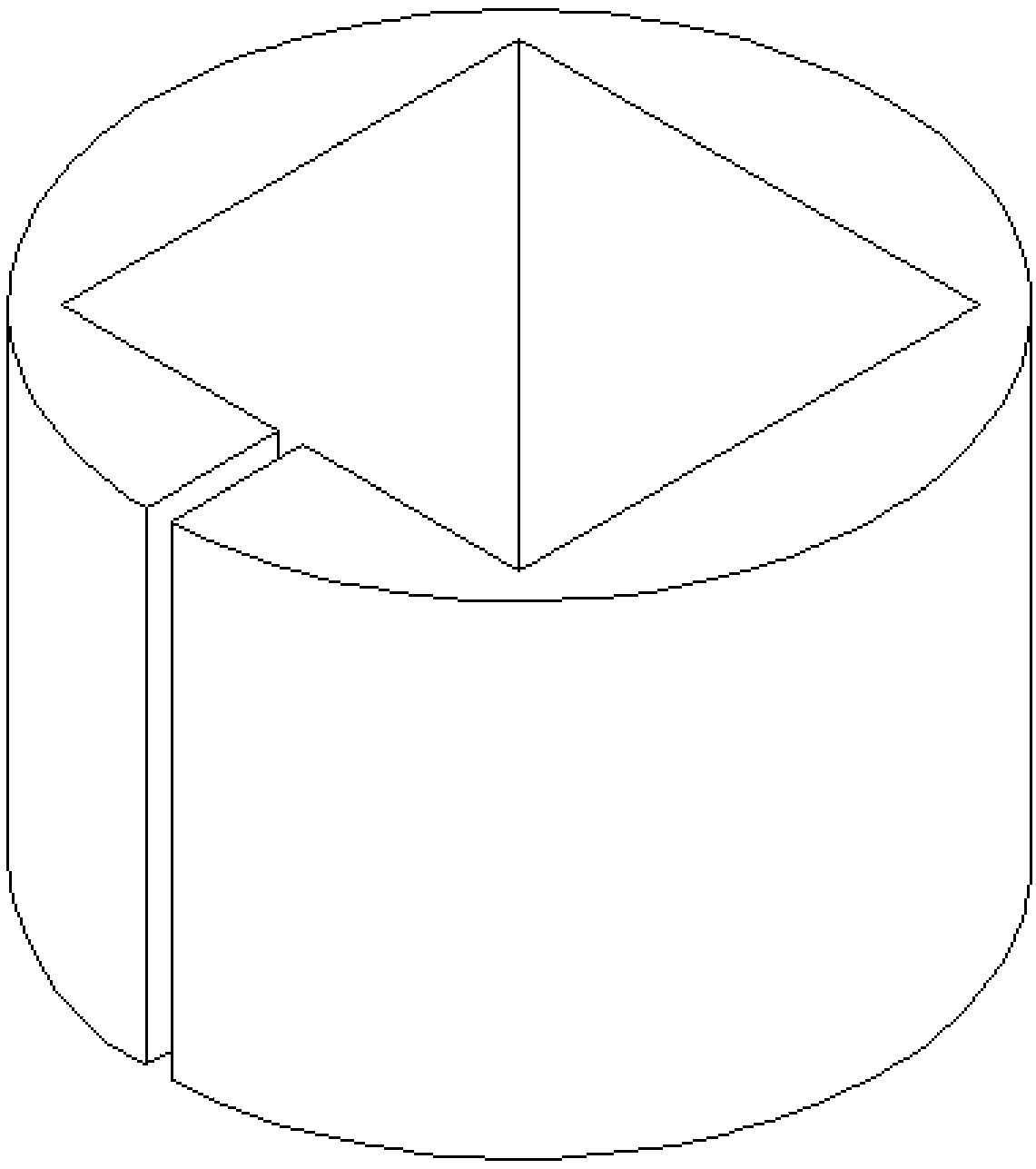

[0019] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a kind of adjustable high-speed friction and wear testing machine fixture described in this embodiment includes connecting block 1, mobile platform 2, fixture sleeve 3 and friction style sleeve 4, the connecting block 1 and mobile platform 2 One end is connected, the clamp sleeve 3 is installed vertically on the mobile platform 2 , and the friction pattern sleeve 4 is inserted in the clamp sleeve 3 .

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, the mobile platform 2 of the fixture for an adjustable high-speed friction and wear testing machine described in this embodiment is provided with a fixture sleeve positioning boss 5, and the fixture sleeve 3 is installed on the fixture sleeve positioning boss 5 Above, at least one fixing bolt 9 for fixing the friction pattern sleeve 4 is provided on the outer wall of the clamp sleeve 3 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, the connection block 1 of the clamp for an adjustable high-speed friction and wear testing machine described in this embodiment is connected with the mobile platform 2, and two guide rails 6 are arranged side by side in parallel. One end face is provided with two slide grooves 2-1 matched with the guide rails 6, and the two guide rails 6 are respectively inserted into the two slide grooves 2-1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com