Lathe pneumatic fixture

A pneumatic clamp and lathe technology, applied in the field of machinery, can solve the problems of small clamping range, cumbersome operation process, and failure to clamp, etc., and achieve the effect of wide application range, convenient clamping and good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

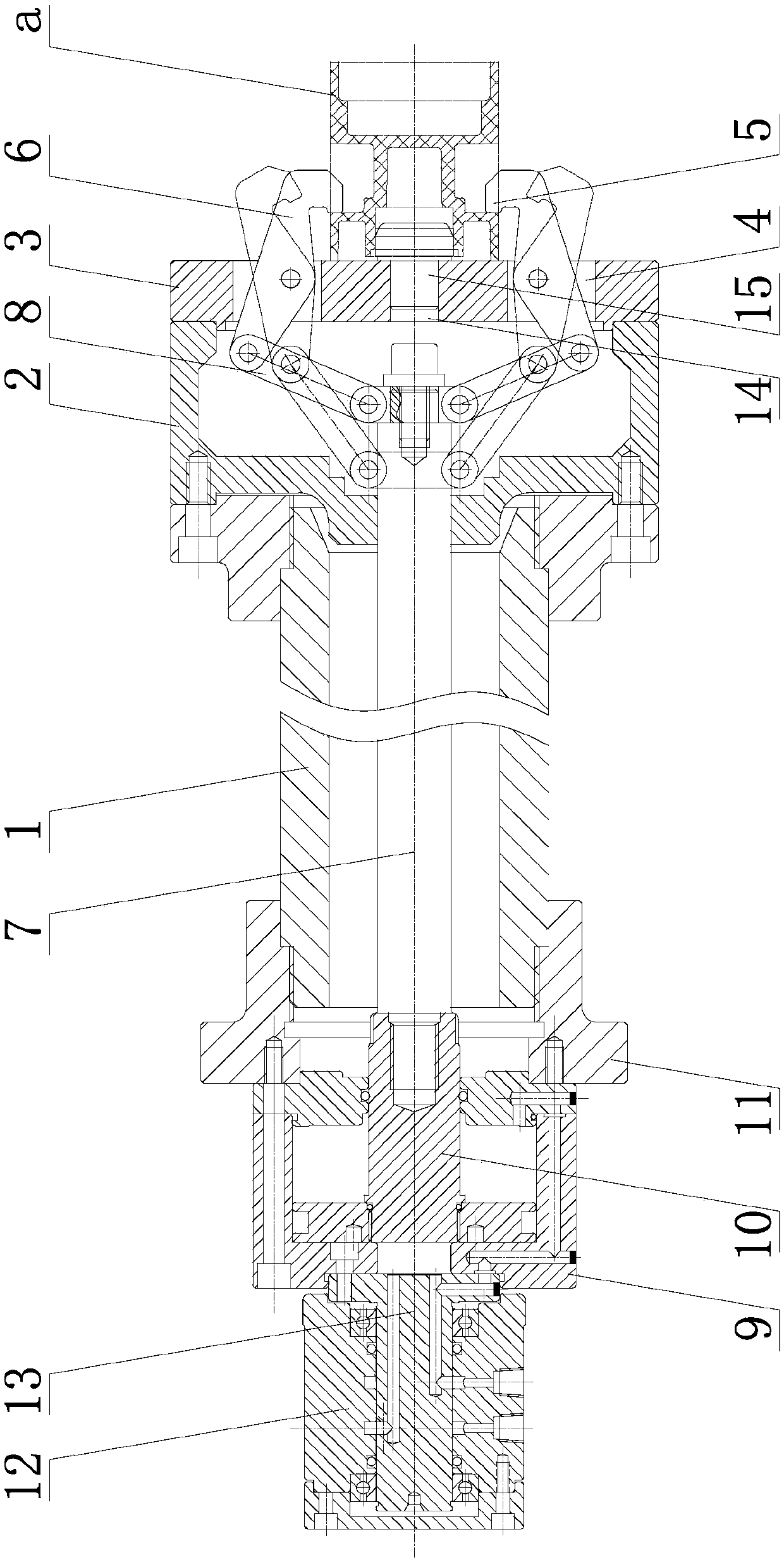

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0021] Such as figure 1 The lathe pneumatic clamp shown is set on the lathe spindle 1 with a shaft hole inside, and includes a clamp body 2 fixed on the front end of the lathe spindle 1. The clamp body 2 has a cavity concave from front to rear, and the clamp body 2 The front end is also provided with a support plate 3 for supporting the workpiece a. The support plate 3 has a number of piercing holes 4 evenly distributed along the central axis of the lathe spindle 1, and each piercing hole 4 is hinged with a belt clamping part 5 The jaws 6 are evenly distributed along the central axis of the lathe spindle 1, and the cavity is provided with a driving assembly for simultaneously driving the jaws 6 to swing around the hinge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com