Automobile air conditioner compressor cylinder block boring machining tool

A technology for compressor cylinder block and automobile air conditioner, which is applied to metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problem of increasing tooling switching and debugging tooling tooling costs, poor verticality between cylinder bore and end face, and increasing workpiece loading. Clamping time and other issues, to avoid the damage of bearing holes and time-consuming and laborious, prevent machining accuracy, and reduce manufacturing and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

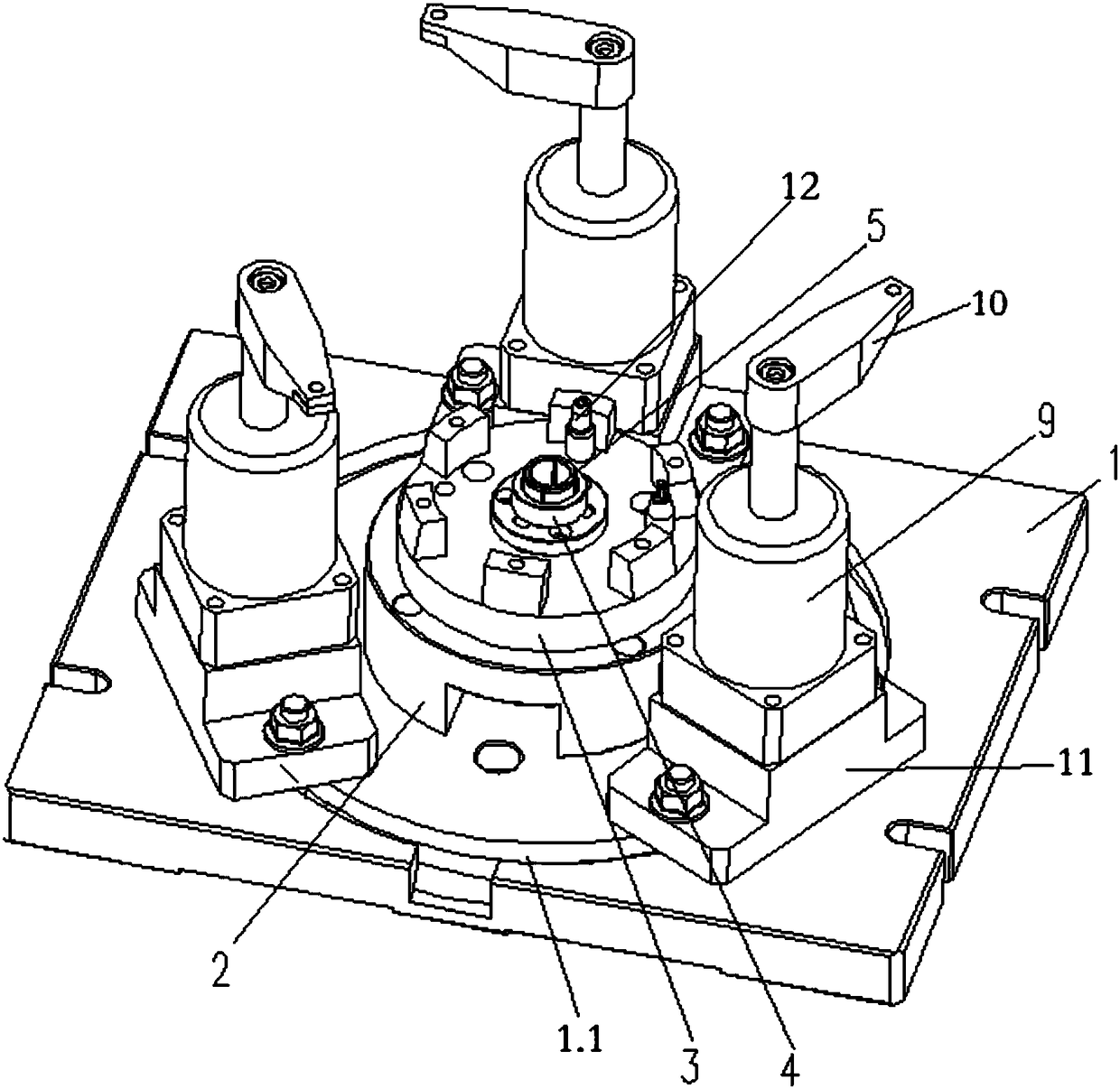

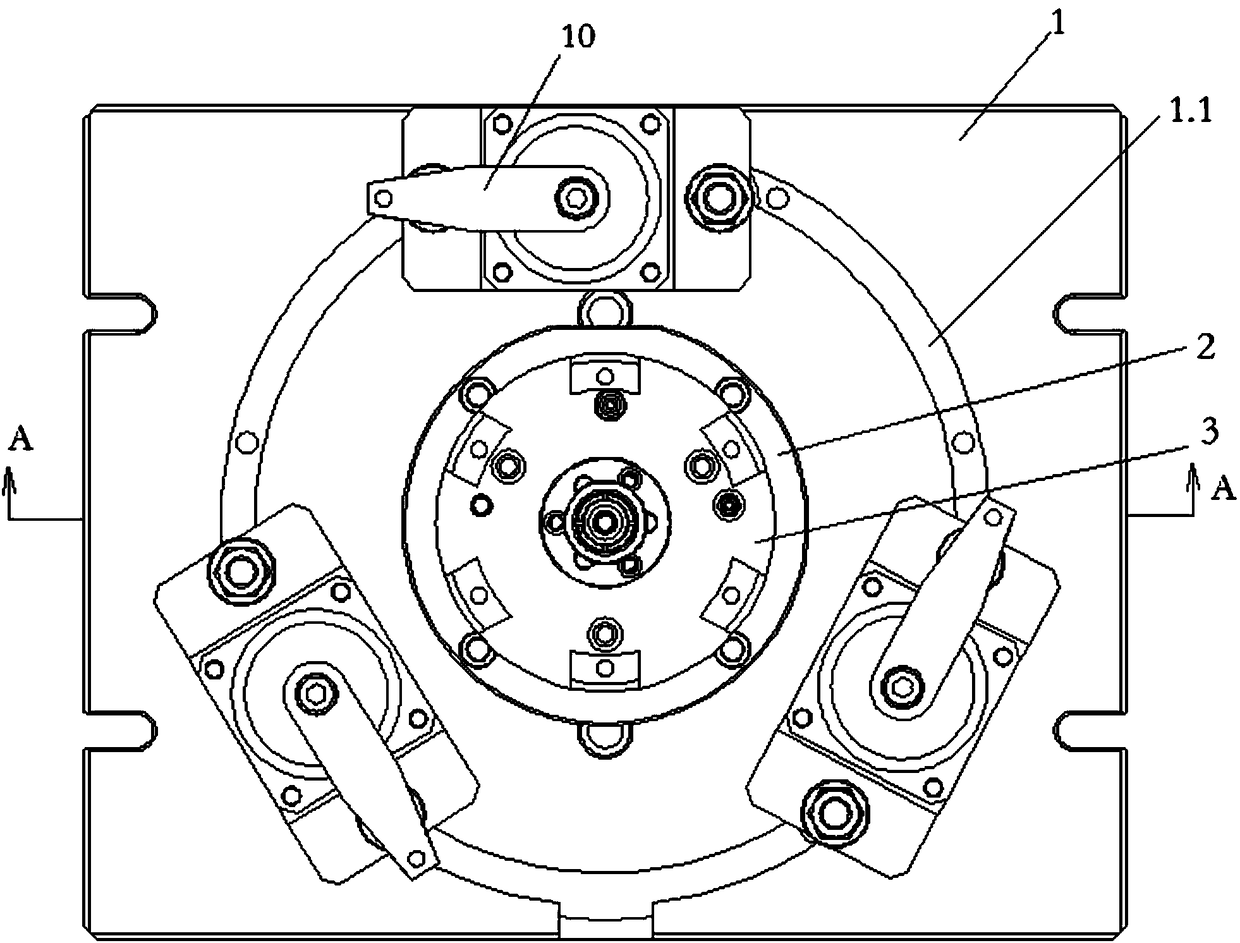

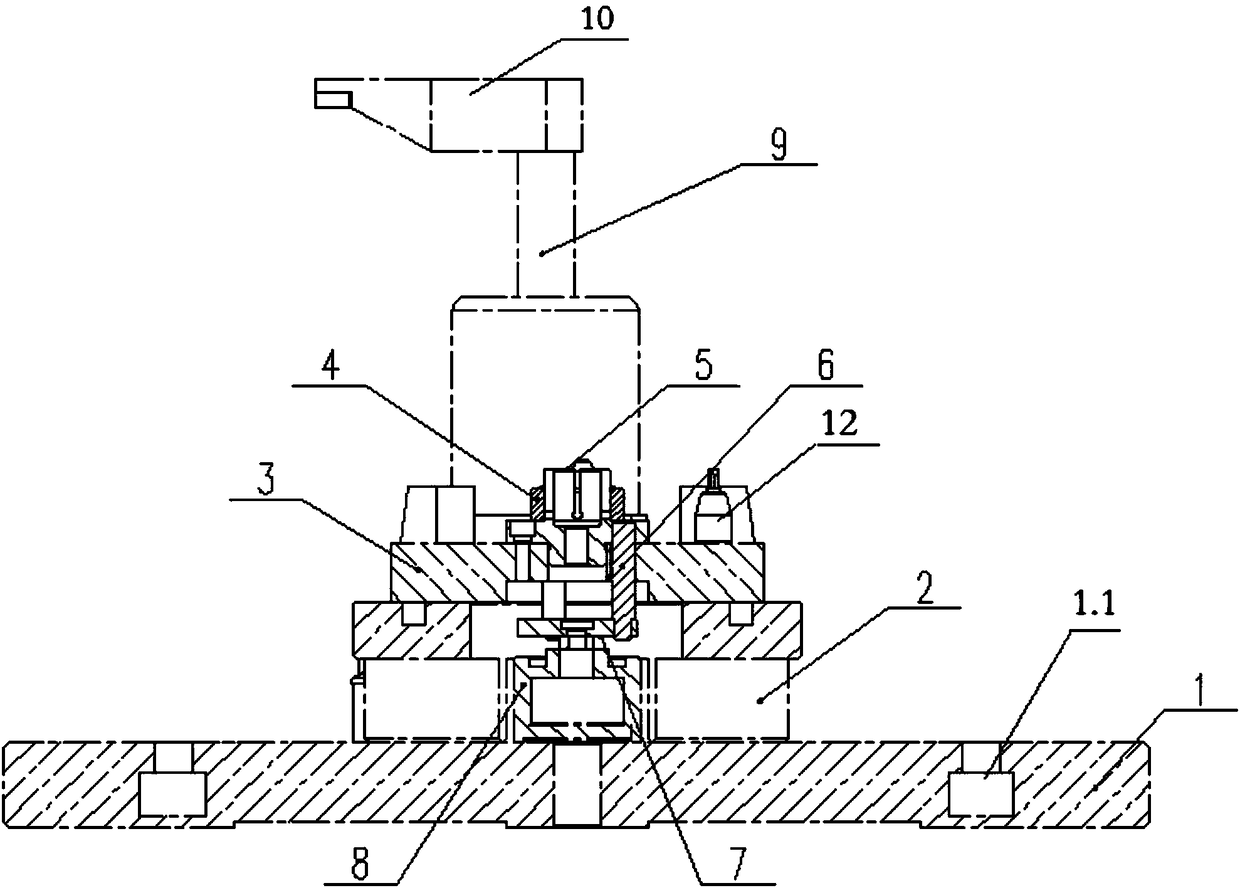

[0026] Such as Figure 1-5 As shown, a boring processing tool for the cylinder block of an automobile air-conditioning compressor includes a base plate 1, a base 2 is fixed in the middle of the base plate 1, and a compression cylinder 9 is fixed on the base plate 1 on the outer periphery of the base 2. , the piston rod of the compression cylinder 9 is connected with a pressure plate 10; the top of the base 2 is fixed with a positioning ring 3, and the center of the positioning ring 3 is fixed with an elastic mandrel 5, and the elastic mandrel The outer peripheral movable sleeve of 5 is provided with a push-out ring 4; the center hole of the base 2 is fixed with a lifting cylinder 8, and the piston end of the lifting cylinder 8 is horizontally fixed with a mounting plate 7, and on the mounting plate 7 A plurality of connecting rods 6 are fixed, and the top ends of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com