Tool for machining thin-walled disc-shaped part of aero-engine

A technology of aero-engine and parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

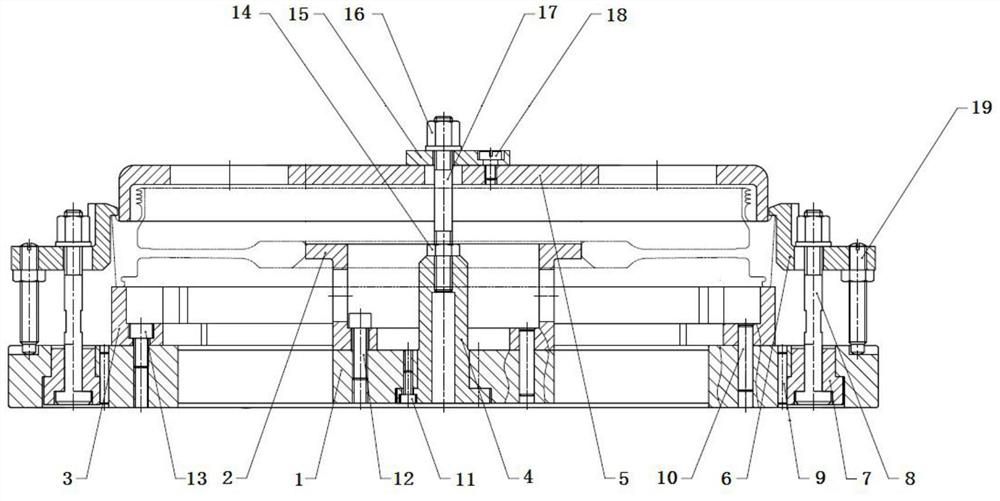

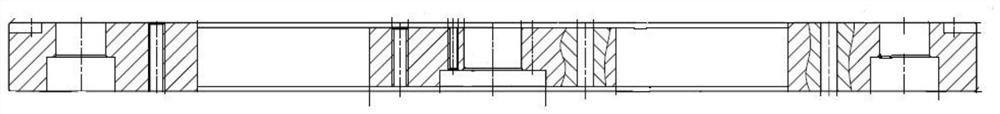

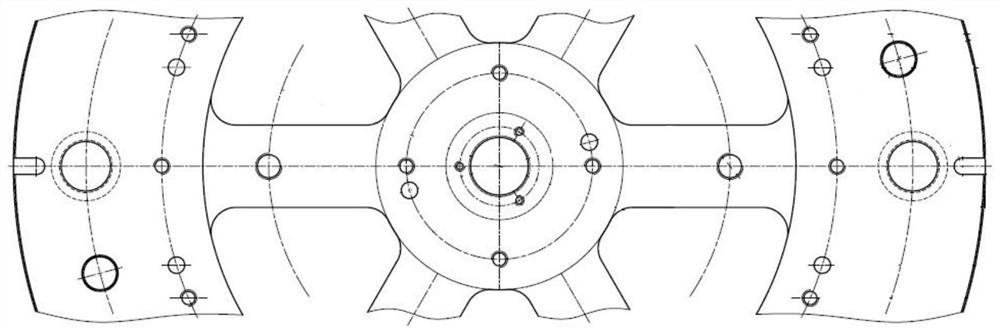

[0030] Such as Figure 1-9 As shown, a tooling for processing thin-walled disc-shaped parts of aero-engines according to the present invention includes a C-shaped circular base 1, a positioning ring 2, a support block 3, a shaft 4, a gland 5, a pressure plate 6, a lining Cover 7, bolt 8, second screw 12, third screw 13, second nut 16, stud 17;

[0031] The C-shaped circular base 1 is a ring-shaped hollow structure in the middle, with mounting threaded holes in the middle, and six evenly distributed countersunk threaded holes on the peripheral annular support surface. The purpose of the countersunk holes is to insert bolts. 8. The C-shaped circular base 1 is connected with the machine tool;

[0032] The locating ring 2 is hollow and annular, and its outer diameter is compatible with the diameter of the inner ring of the part to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com