Device and method of laser impact welding in warm state

A laser shock and heating technology, applied in laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of inability to heat temperature monitoring, low workpiece clamping accuracy, easy to break, etc., to improve welding efficiency and automation. High, precise clamping results for welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

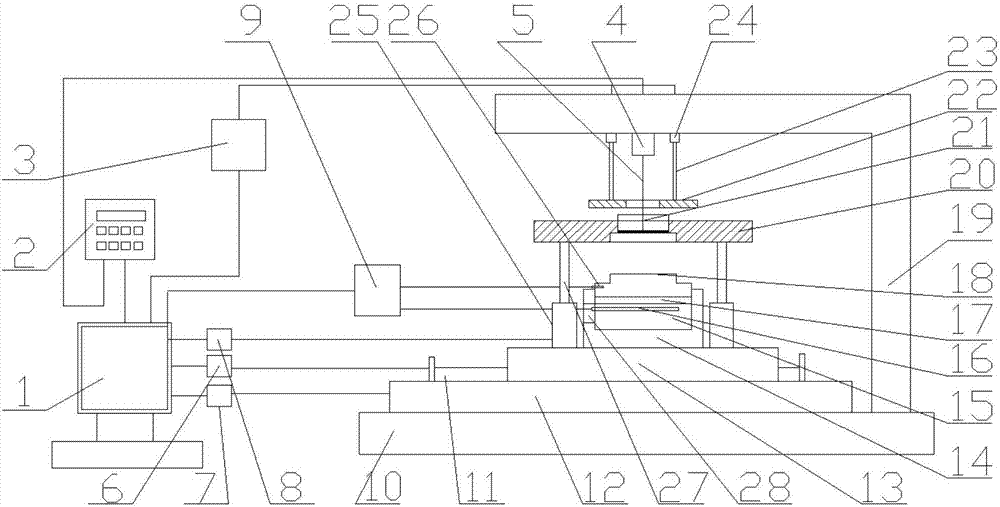

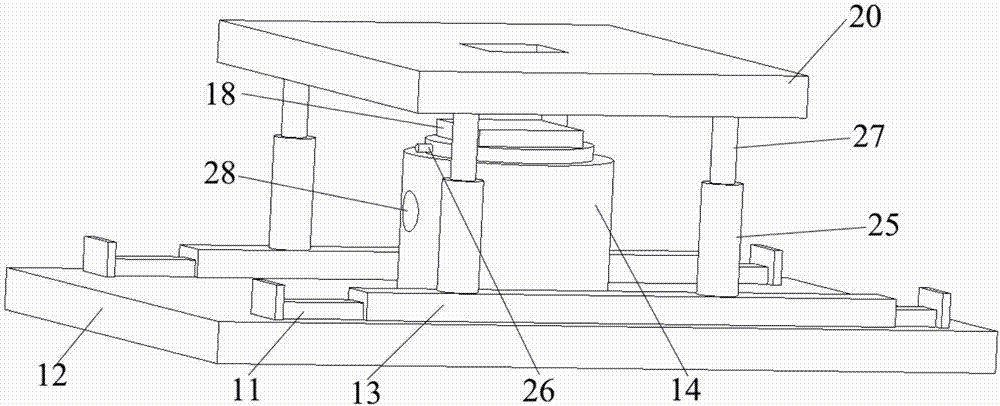

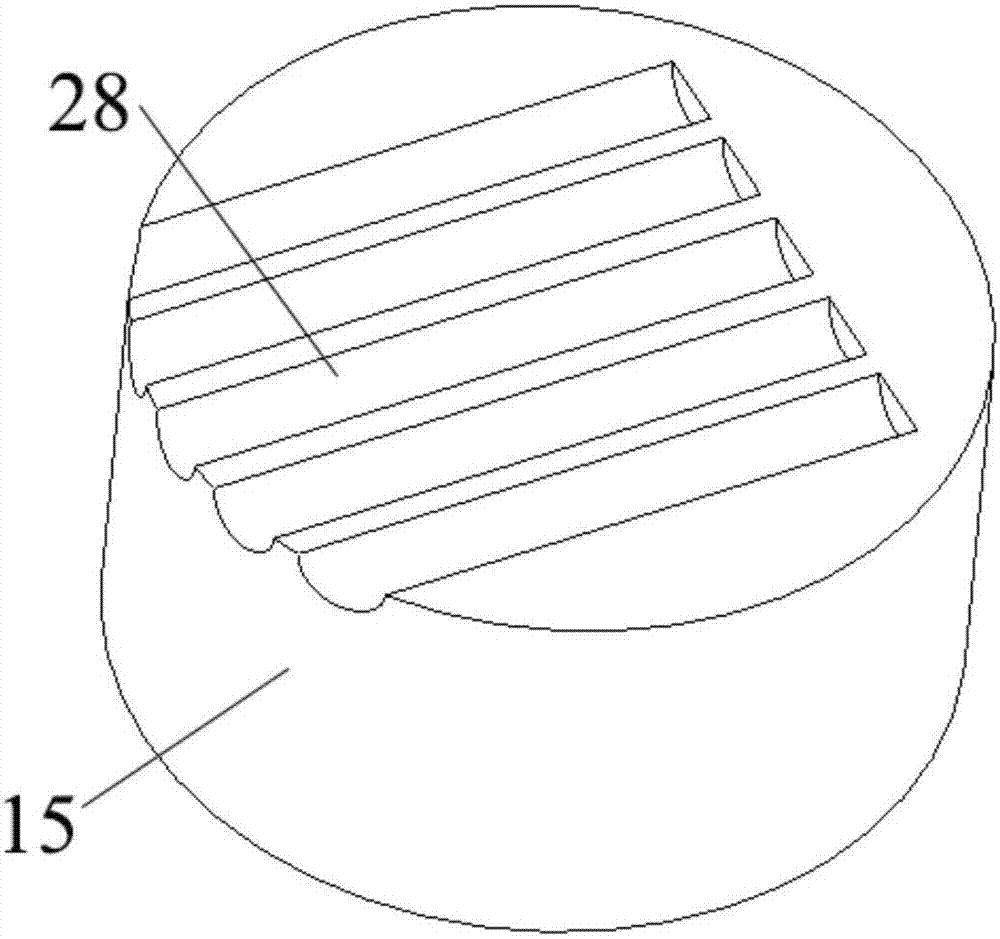

[0030] combined with Figures 1 to 4 , a device for laser shock welding in a warm state, the device includes a laser emitting system, a control system, and a workpiece warm welding operating system;

[0031]The laser emitting system includes a computer 1, a laser controller 2, a nanosecond laser 4, and a laser beam 5; the computer 1, the laser controller 2, and the nanosecond laser 4 are connected in sequence to form a laser light path, and the nanosecond laser 4 Connected on the inverted L-shaped support 19 by thread, the inverted L-shaped support 19 is installed on the base 10; the control system includes a three-dimensional mobile platform controller 7, a hydraulic controller 8, a slide rail controller 6, and a heating device controller 9 and the hydraulic small thimble controller 3, the three-dimensional mobile platform controller 7 realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com