Laser preprocessing and restoring method and device having on-line detection function and used for optical elements

A technology of laser pretreatment and optical components, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of slowing down the growth rate of damage points, and achieve the effects of simplifying the processing and manufacturing process, saving costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

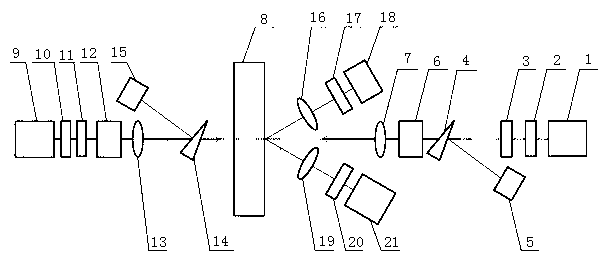

[0025] See figure 1 , a device for laser pretreatment and repair of optical elements with on-line detection applied to reflective optical elements, including a laser pretreatment and repair system and an online detection system; the laser pretreatment and repair system includes relative optical elements 8- The pretreatment light source or repair light source 1 set on the surface (front surface or back surface), and the first light set at the rear end of the pretreatment light source or repair light source 1 and at the front end of a surface (front surface or back surface) of the optical element 9 in sequence The switch 2, the light energy adjusting device 3 and the first splitting wedge 4 are arranged behind one output end of the first splitting wedge 4. The first light energy detecting device 5 is arranged behind the other output end of the first splitting wedge 4. And the first beam shaping processing device 6 and the first beam focusing device 7 located at the front end of ...

Embodiment 2

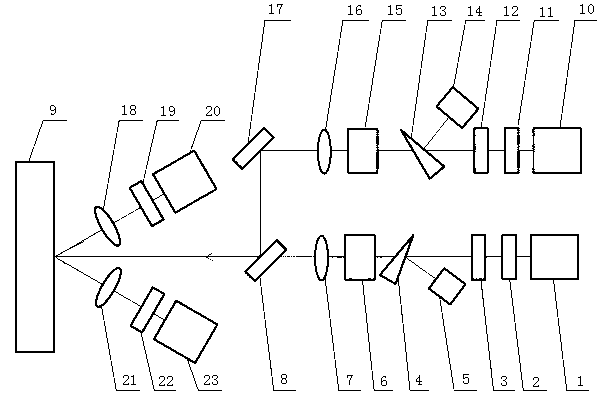

[0032] See figure 2 , a device for optical element laser pretreatment and repair with on-line detection applied to transmissive optical elements, including a laser pretreatment and repair system and an online detection system; the laser pretreatment and repair system includes a relative optical element 9- The pretreatment light source or repair light source 1 set on the surface (front surface or back surface), and the first light set at the rear end of the pretreatment light source or repair light source 1 and at the front end of a surface (front surface or back surface) of the optical element 9 in sequence The switch 2, the light energy adjusting device 3 and the first splitting wedge 4 are arranged behind one output end of the first splitting wedge 4. The first light energy detecting device 5 is arranged behind the other output end of the first splitting wedge 4. And the first beam shaping processing device 6, the first beam focusing device 7 and the dichroic mirror 8 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com