Method for realizing lossless evaluation for damage performance of optical element

A technology for optical components and performance, applied in the field of non-destructive evaluation of optical components, can solve problems such as small scale, damage of optical components, and improvement of laser output, and achieve the effect of achieving damage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

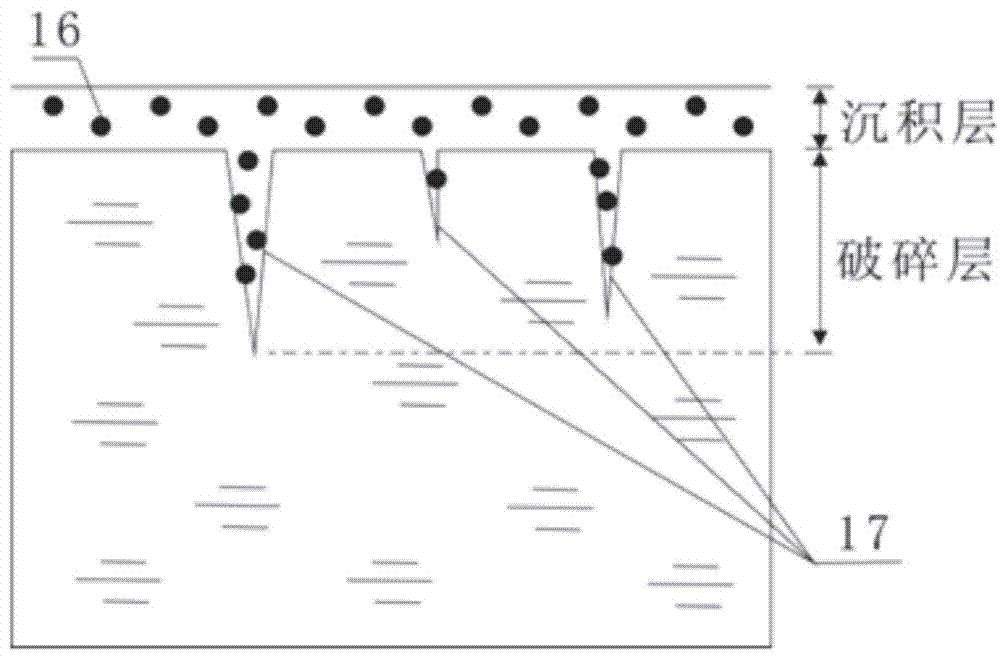

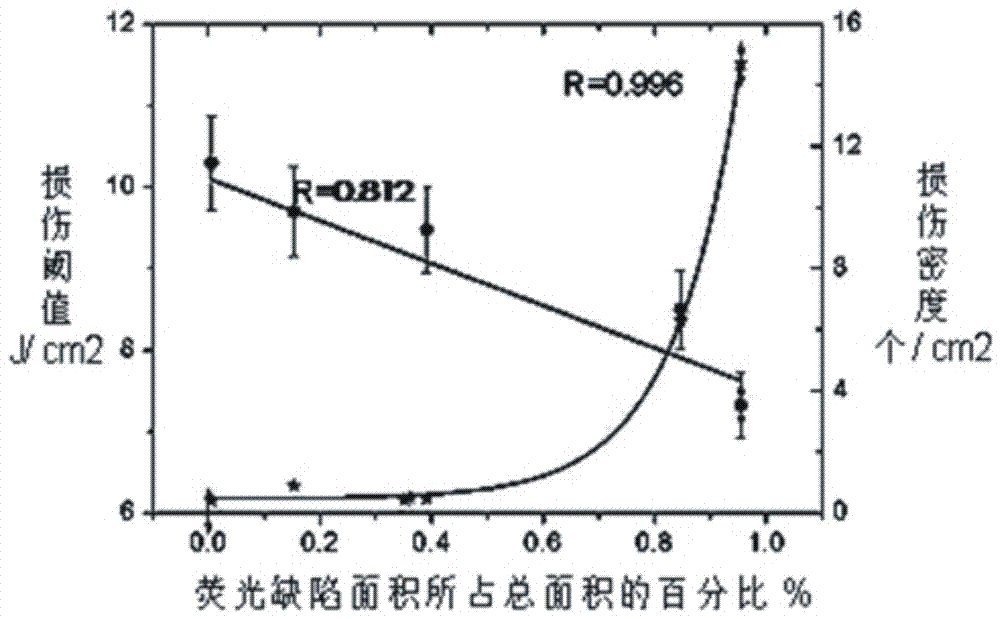

[0029] Embodiment 1: see figure 1 , the surface of sample 5 is divided into a sedimentary layer and a broken layer. The surface of the sedimentary layer is polished, and there are many microcracks 17 in the broken layer below it. Both the sedimentary layer and the broken layer contain impurities 16. Based on the damage mechanism of the optical element, that is, the subsurface microcracks 17 embedded in the polluting impurities 16 are easy to absorb high-flux laser energy to cause damage under laser irradiation. For the buried polluting impurities 16, the corresponding fluorescent defects are obtained by detecting the fluorescence emitted by them.

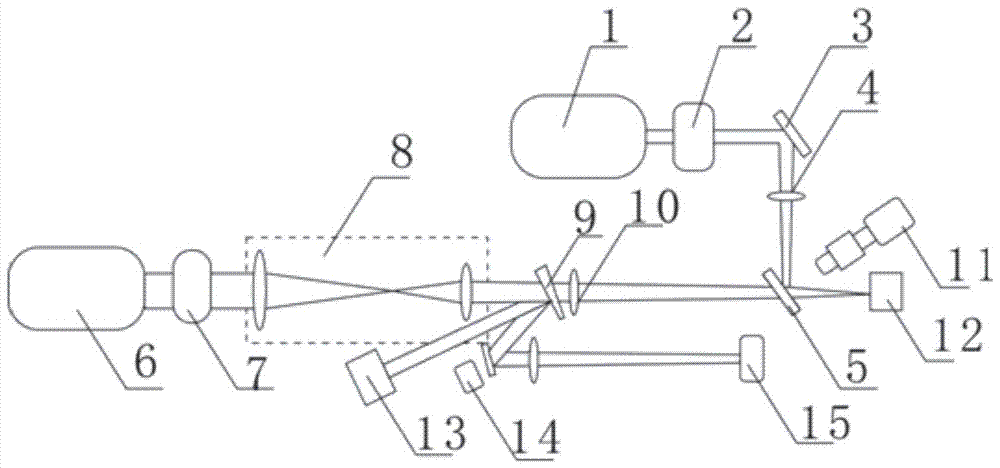

[0030] see figure 2 with image 3 , in order to test, must use optical path system, we construct a kind of optical path system for the present invention, described optical path system comprises continuous laser 1, pulsed laser 6, sample stage, microscopic imaging system 11, sample stage can move three-dimensionally And the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com