Hollow light guiding cone coupling vacuum transmission laser device

A vacuum transmission and transmission device technology, applied in the coupling of optical waveguides, etc., can solve the problems of easily damaged fiber input end face, high power density, and high laser power density at the fiber end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention realizes the coupling of high-power laser into the optical fiber by adopting the hollow light guide cone of the non-imaging element, and increases the laser damage threshold of the optical fiber end face due to the increase of the light-receiving area of the injection end face. The use of hollow light guide cone and vacuum pumping technology inside the optical fiber improves the transmission efficiency of the optical fiber transmission system, reduces laser damage, and increases the laser capacity of optical fiber transmission.

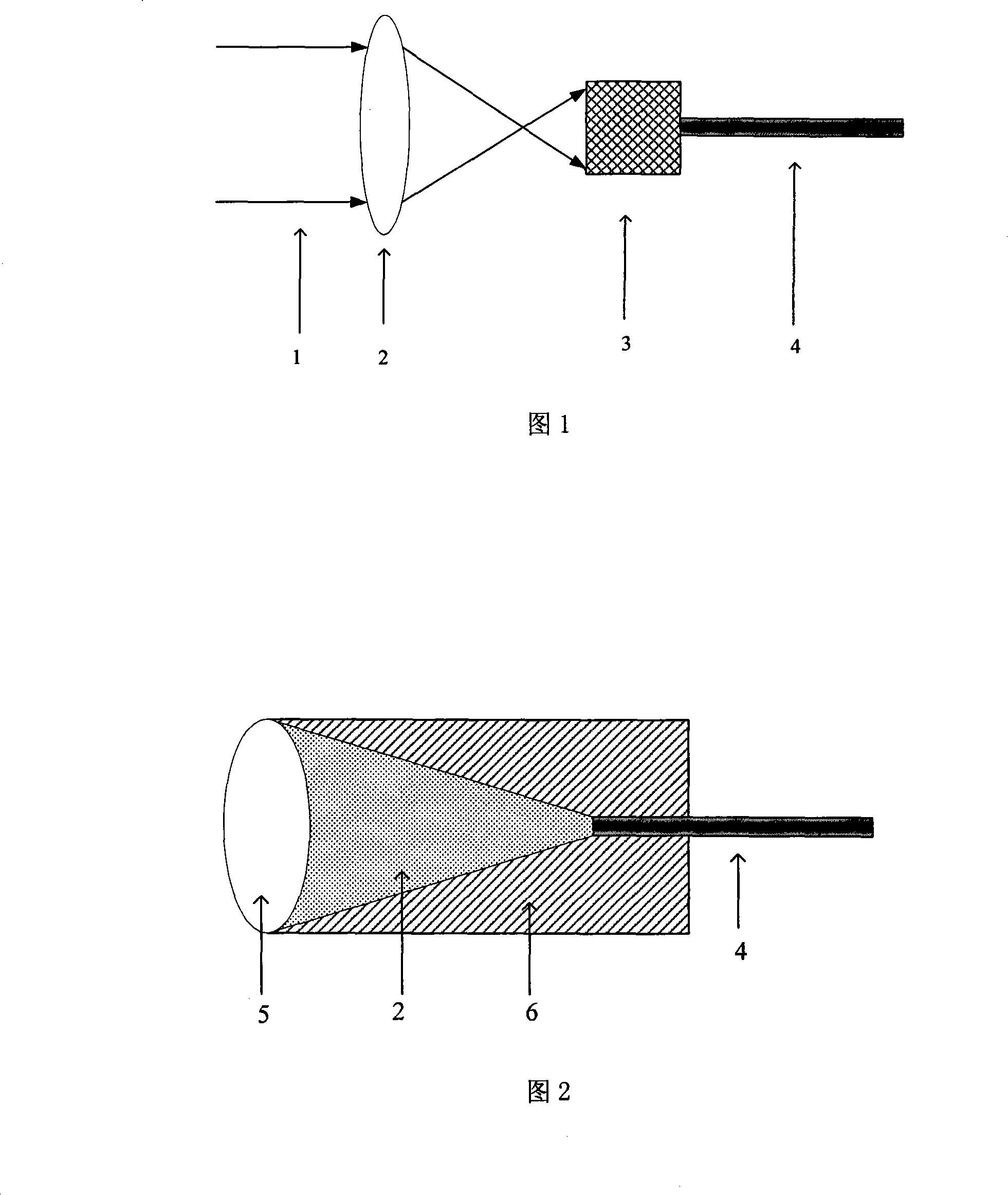

[0022] Figure 1 is a schematic diagram of a hollow light guide cone coupled vacuum transmission device. In the figure, the laser light 1 is focused by the focusing lens 2, and a suitable injection spot size is obtained at the large end of the hollow light guide cone 3, and the input end of the optical fiber 4 is connected with the small end of the hollow light guide cone 3. The laser light 1 is focused by the lens 2 and injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com