ArF laser film element irradiation damage test device with high irradiation density uniformity

A laser thin film and testing device technology, applied in the measurement of scattering characteristics, etc., can solve the problems of differentiation, complex damage mechanism, and many factors of damage to ArF laser thin film components, and achieve reduced uncertainty, high uniformity, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

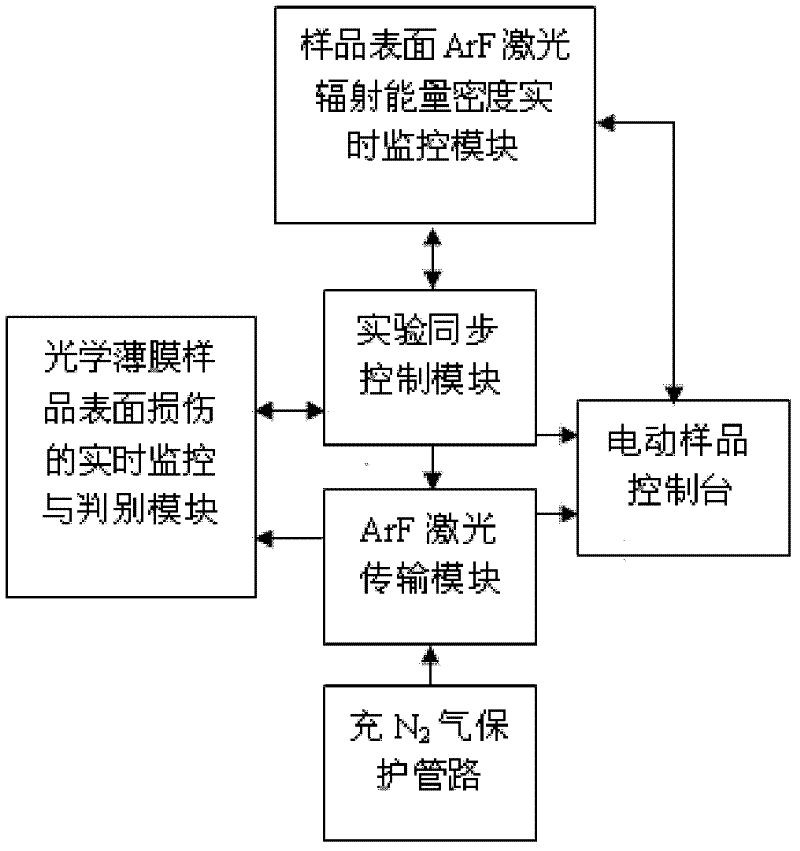

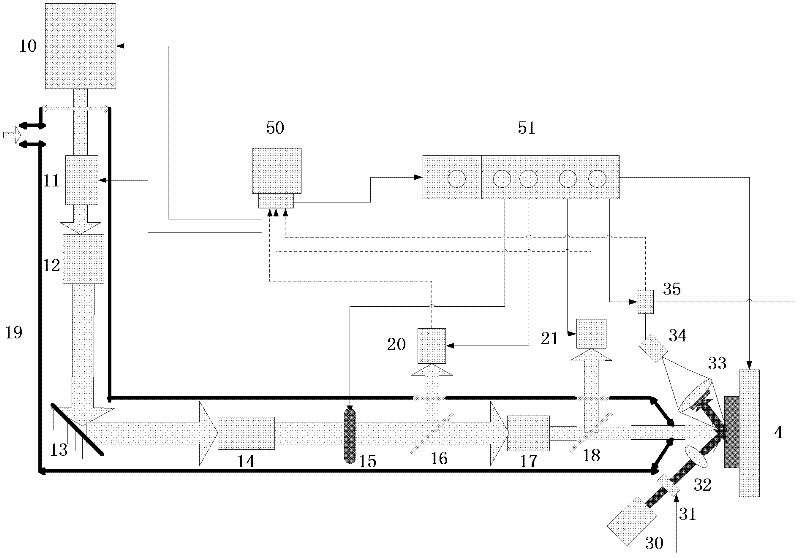

[0015] Depend on figure 1 As shown, the ArF laser thin film element damage test device with high uniformity of irradiation density, the device includes: ArF laser transmission module, real-time monitoring module of ArF laser radiation energy density on the sample surface, real-time monitoring and discrimination module of optical film sample surface damage, Motorized sample console and experimental synchronization control and data acquisition module;

[0016] The ArF laser transmission module emits and transmits the ArF laser with high uniformity of radiation energy density, and radiates to the sample surface through two beam splitter mirrors in the ArF laser radiation energy density real-time monitoring module;

[0017] The real-time monitoring module of the ArF laser radiation energy density on the sample surface is used to obtain the ArF laser radiation energy density of the sample surface, control its measurement action through the experiment synchronization control module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com