Multifunctional high-efficiency laser damage test device and method in vacuum environment

A vacuum environment, high-efficiency technology, applied in the direction of testing optical properties, can solve the problems of breaking vacuum, low efficiency, single function, etc., and achieve the effect of saving time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

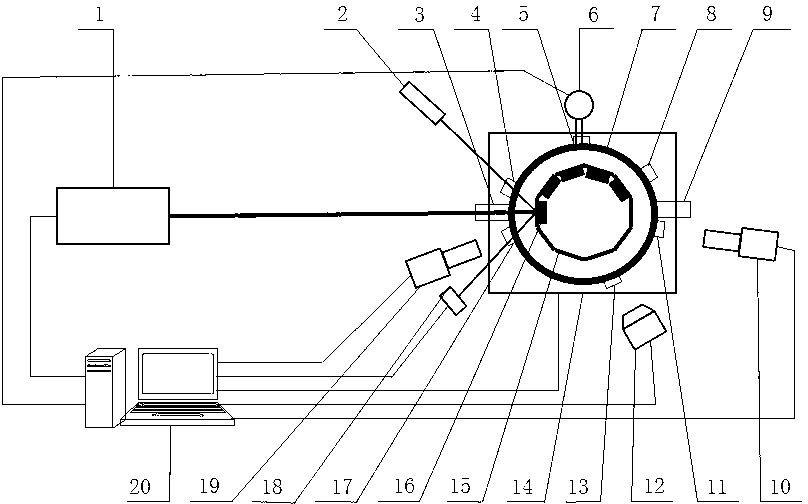

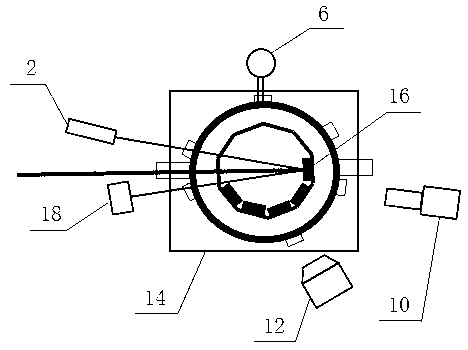

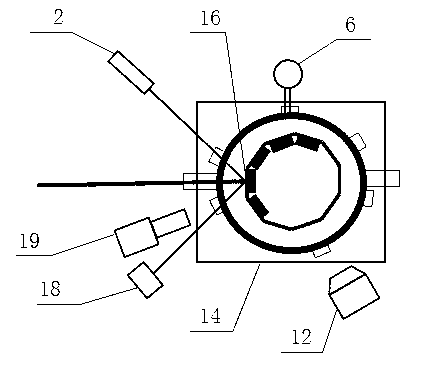

[0031] Embodiment 1: see figure 1, Nd:YAG laser 1, He-Ne detection laser 2, pressure detection element 6, vacuum chamber 7, first CCD camera 10, high power microscope 12, motor system 14, tested sample 16, photoelectric detection element 18, second CCD Camera 19 and computer 20. The components of the vacuum cavity 7 include a laser incident window 3, a laser exit window 9, a detection laser entrance window 4, a detection laser exit window 17, a pressure detection window 5, a CCD camera monitoring window 11, a vacuum pump window 8, an offline observation window 13 and a rotating Sample stage 15. in:

[0032] The tested sample 16 is placed on the rotating sample stage 15 in the vacuum chamber 7 , and the vacuum chamber 7 is fixed on the motor system 14 .

[0033] The motor system 14 includes a motorized translation stage and a rotation motor.

[0034] The sample to be tested 16 together with the vacuum chamber 7 is controlled by an electric moving translation stage to move h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com