Laser damage resistance testing system

A test system and anti-damage technology, applied in the direction of testing optical properties, etc., can solve the problems such as the inability to effectively and accurately judge the damage resistance of the sample, the single judgment method, and the inability to change the power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

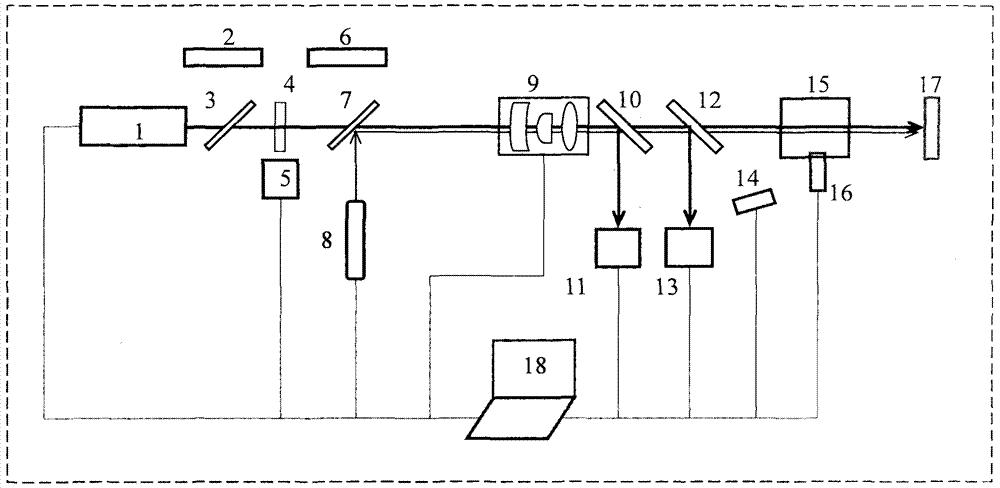

[0020] The laser damage resistance testing system includes: pulse laser 1, first light baffle plate 2, first polarizer 3, first 1 / 2 wave plate 4, first electric control rotary table 5, second light baffle plate 6, second polarizer 7. Indicating light source 8, electronically controlled zoom system 9, first 45° partial reflector 10, CCD spot analyzer 11, second 45° partial reflector 12, energy meter 13, photoelectric detector 14, lofting room 15, monitoring Camera 16, third light barrier 17, control system 18.

[0021] The connections between the components are:

[0022] Along the direction of the optical axis, the following components are arranged in sequence: pulsed laser 1, first polarizer 3, 1 / 2 wave plate 4, second polarizer 7, electronically controlled zoom system 9, first 45° partial reflector 10, second polarizer Two 45° partial reflector 12, lofting room 15, monitoring camera 16, third light blocking plate 17;

[0023] The first electronically controlled rotary table...

Embodiment 2

[0043] Other structures are the same as in Embodiment 1, and the anti-damage testing system also includes a second 1 / 2 wave plate 19, and a second electrically controlled rotary table 20, that is, there are two 1 / 2 wave plates between the pulse laser and the electronically controlled zoom system. The distribution of the wave plate and two polarizers along the optical axis is:

[0044] The pulse laser, the second 1 / 2 wave plate 19, the first polarizer 3, the first 1 / 2 wave plate 4, the second polarizer 7, and the electronically controlled zoom system 9 are arranged in the direction of the optical axis in sequence, and other components and their arrangement Same as in the first embodiment. The second electronically controlled rotating stage 20 controls the rotation angle of the second 1 / 2 wave plate 19 .

[0045] This structure can effectively fine-tune the output power of the laser, so that the laser power density of the final spot can reach about 0-100MW / cm 2 , 0-200MW / cm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com